Computer subsidiary product assembling sequence generation method

A computer-aided, assembly sequence technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as the generation of large-scale complex product assembly sequences, and achieve the effect of improving flexibility, efficiency, and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

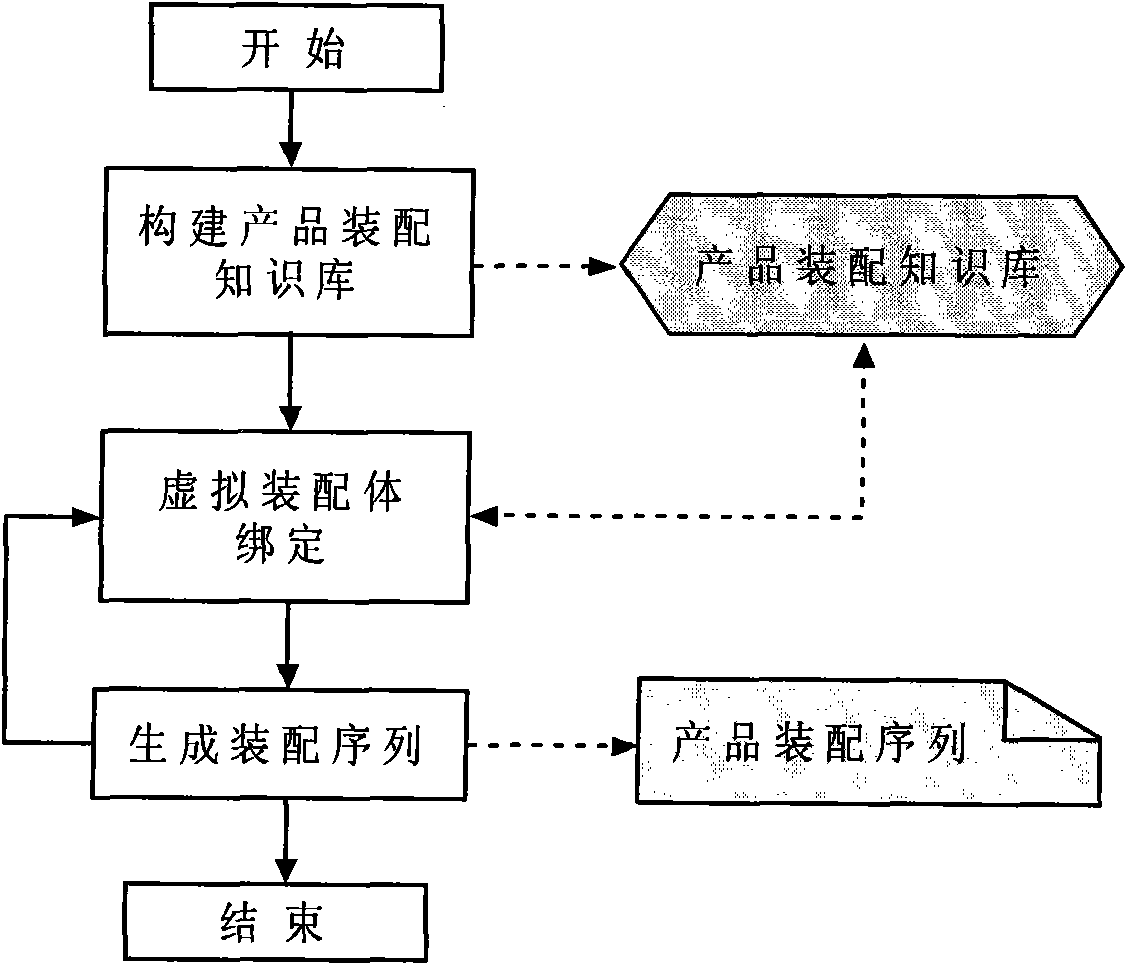

[0020] figure 1 It is a flowchart of a method for generating a computer-aided product assembly sequence proposed by the present invention, including:

[0021] Step 1. Based on the hierarchical task network planning method, construct the product assembly knowledge base structure;

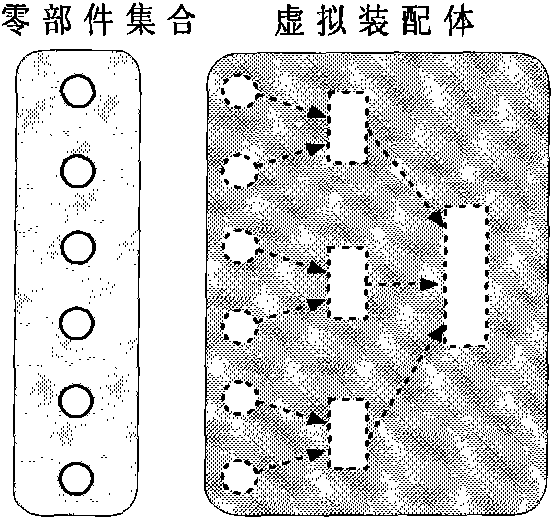

[0022] Step 2, the virtual assembly binding process, guided by the hierarchical structure of the virtual assembly and the connection structure of the components, binds the actual components to the corresponding virtual components of the virtual assembly;

[0023] Step 3, generate product assembly sequence based on virtual assembly binding.

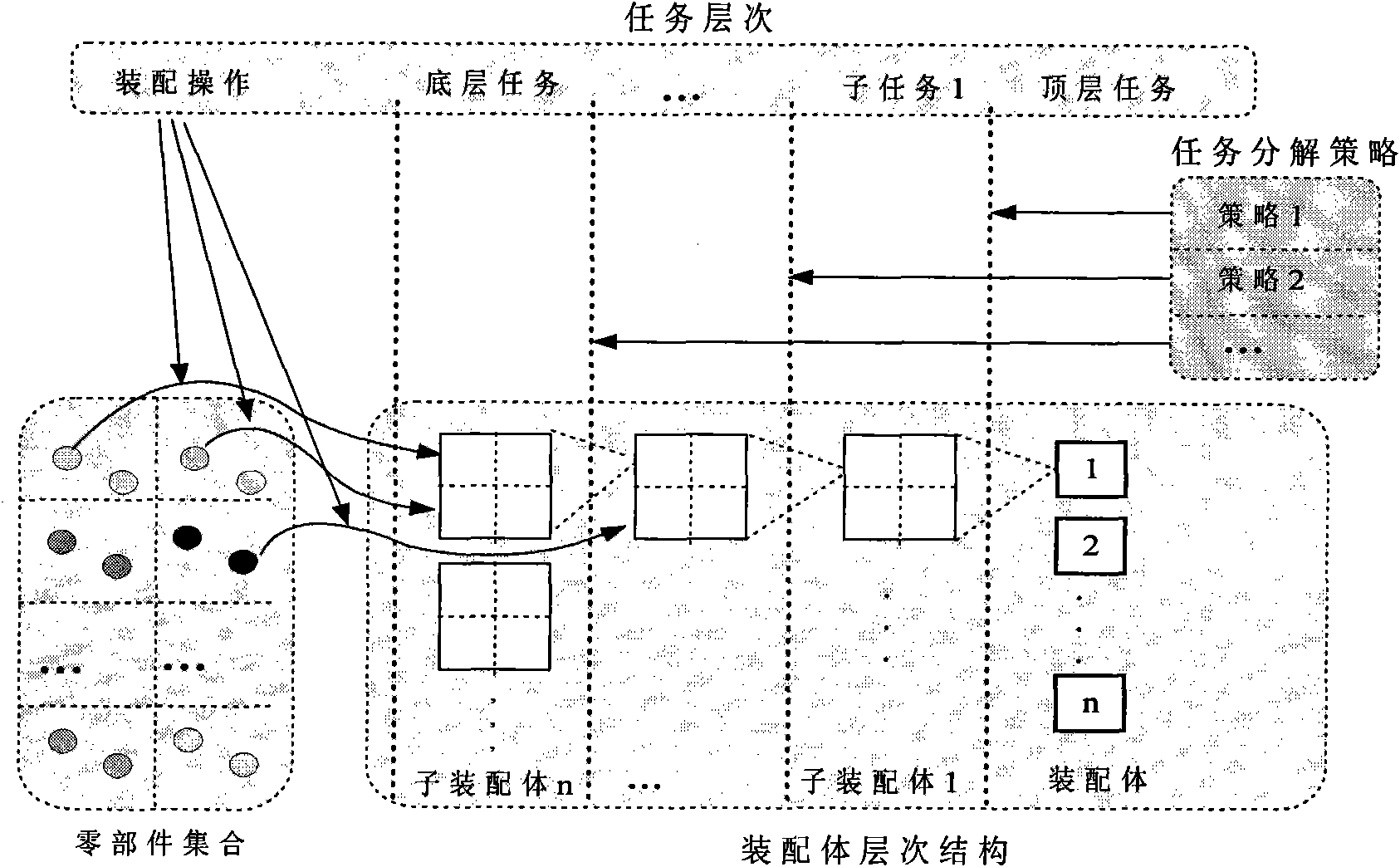

[0024] figure 2 is a schematic diagram of the structure of the product assembly knowledge base, in figure 2 In , the structure of the product assembly knowledge base is composed of four parts: component collection, assembly hierarchy, tas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com