Cotton picker spindle with grease reservoir and a grease and dirt seal

一种摘棉机、锭子的技术,应用在棉花收获机的锭子领域,能够解决增加大量阻力、增加所需动力、密封装置不实用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation plan

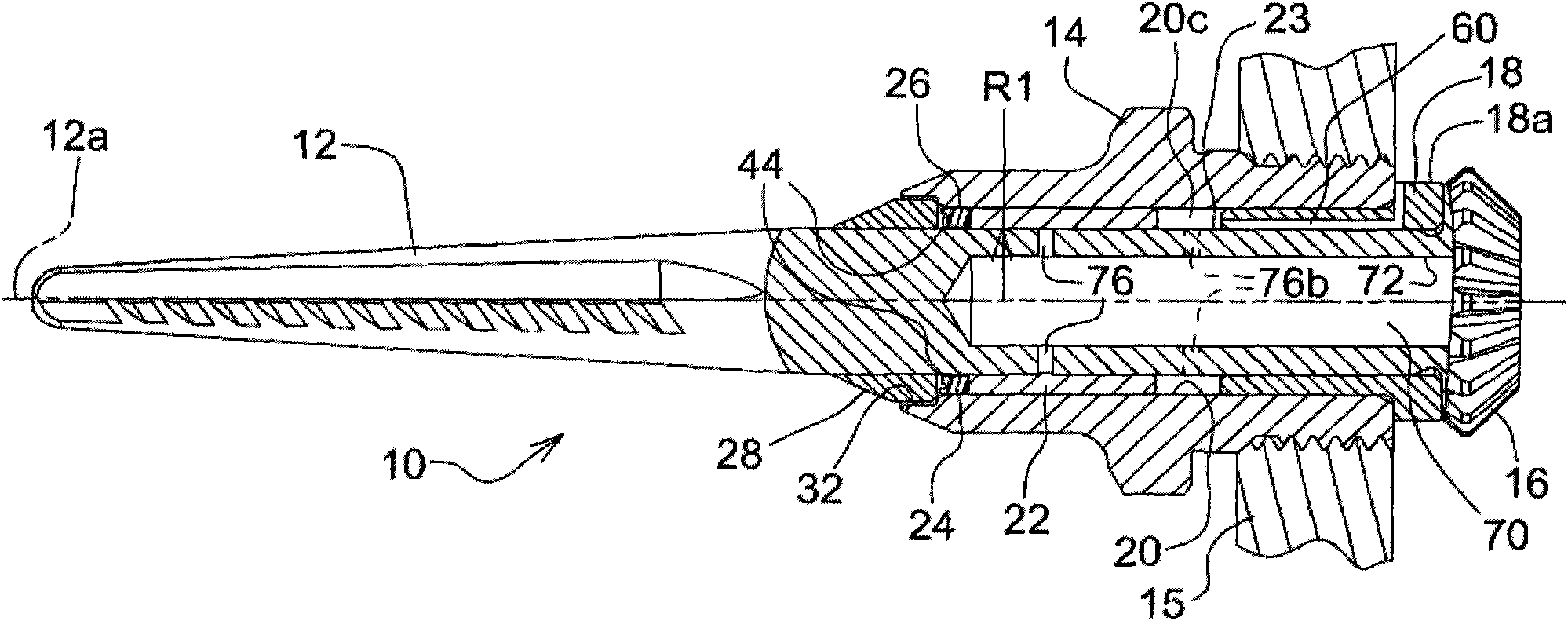

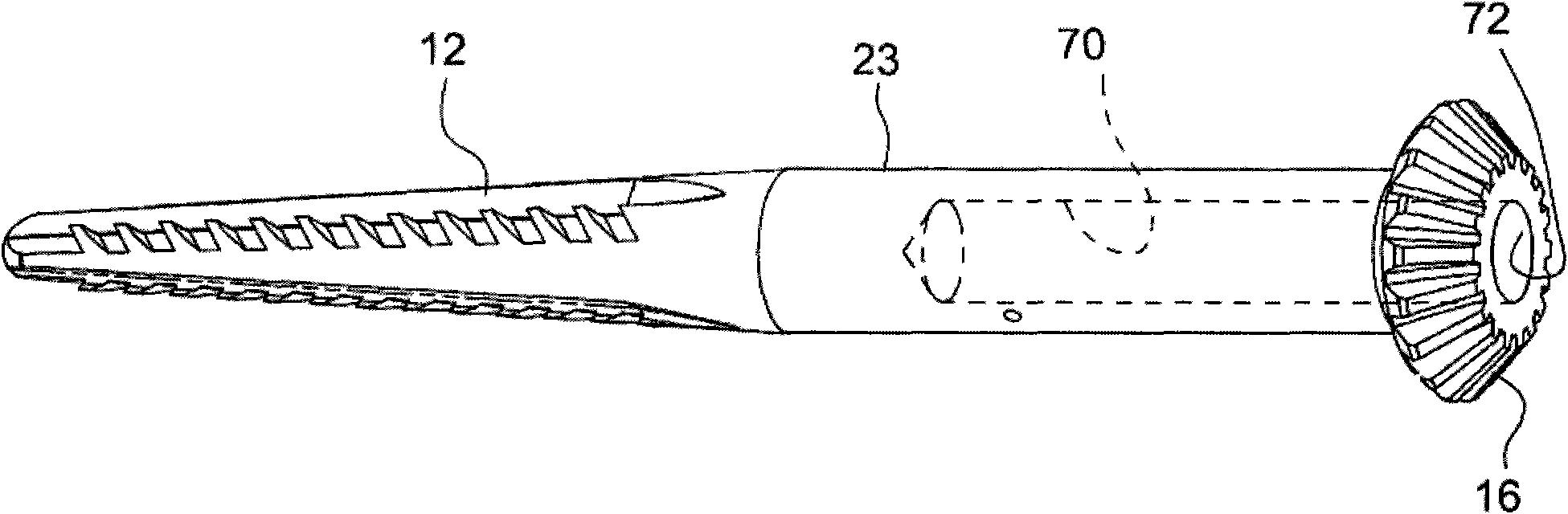

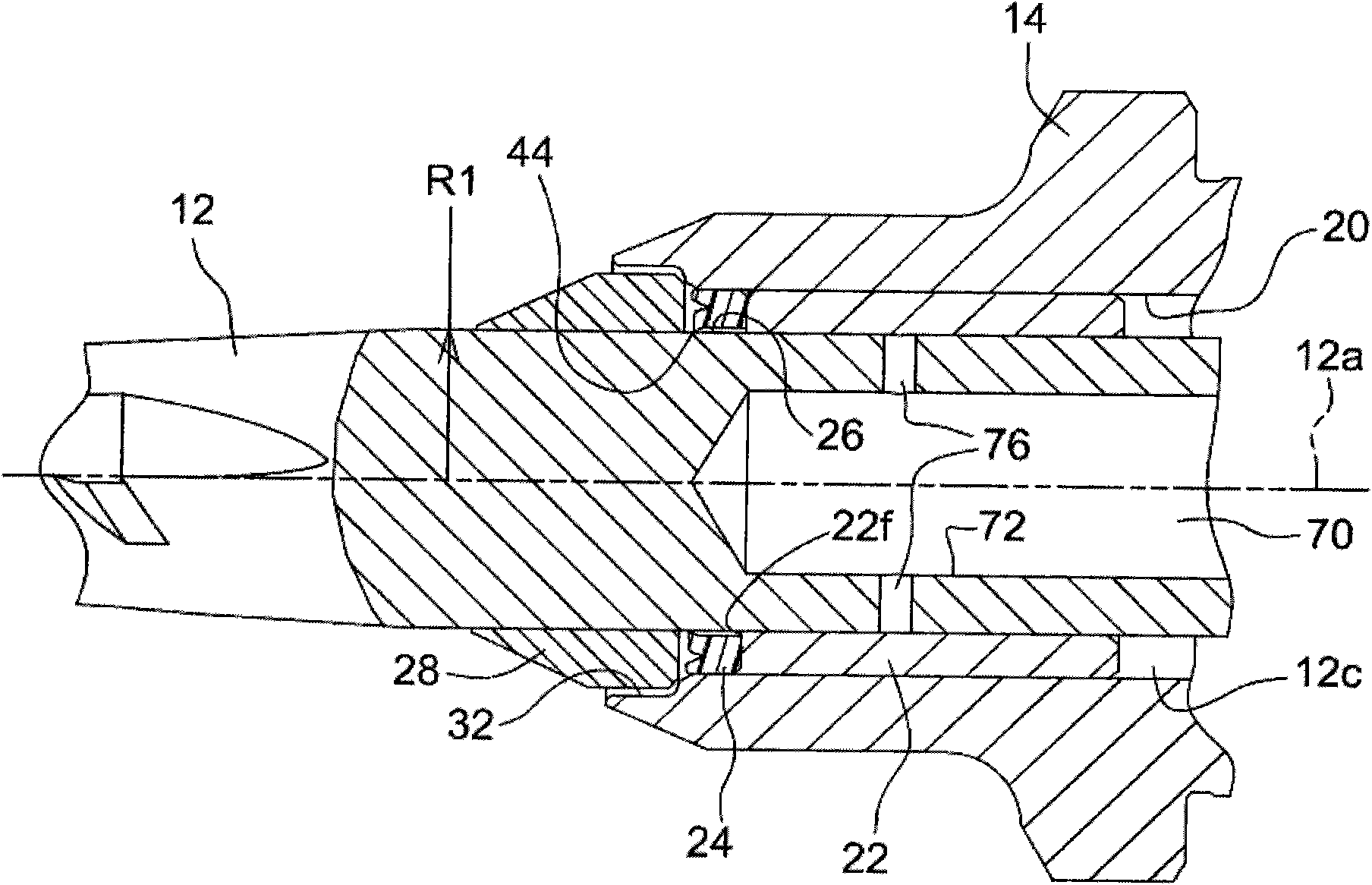

[0017] Such as figure 1 As shown, a spindle assembly 10 is shown which includes a barbed picking spindle 12 which rotates within a conventional spindle nut 14 about a spindle axis 12a. Spindle nut 14 is threaded and adapted to be mounted on an upright picker rod, a portion of which is indicated at 15 . Spindle 12 includes a bevel gear 16 adapted to cooperate with a similar bevel gear (not shown) supported for rotation within picking bar 15 . For further details on the picking bar assembly and drive arrangement reference can be made to US Patent No. 4,463,543 issued to Hubbard et al. and incorporated herein by reference.

[0018] Assembly 10 includes a first or inner bushing 18 which is press-fitted into a cylindrical bore 20 in shaft nut 14 ; Fitted into the bore 20 and offset axially outward from the outer end of the bushing 18 to define an annular cavity 20c surrounding the cylindrical journal region or shank 23 of the spindle 12; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com