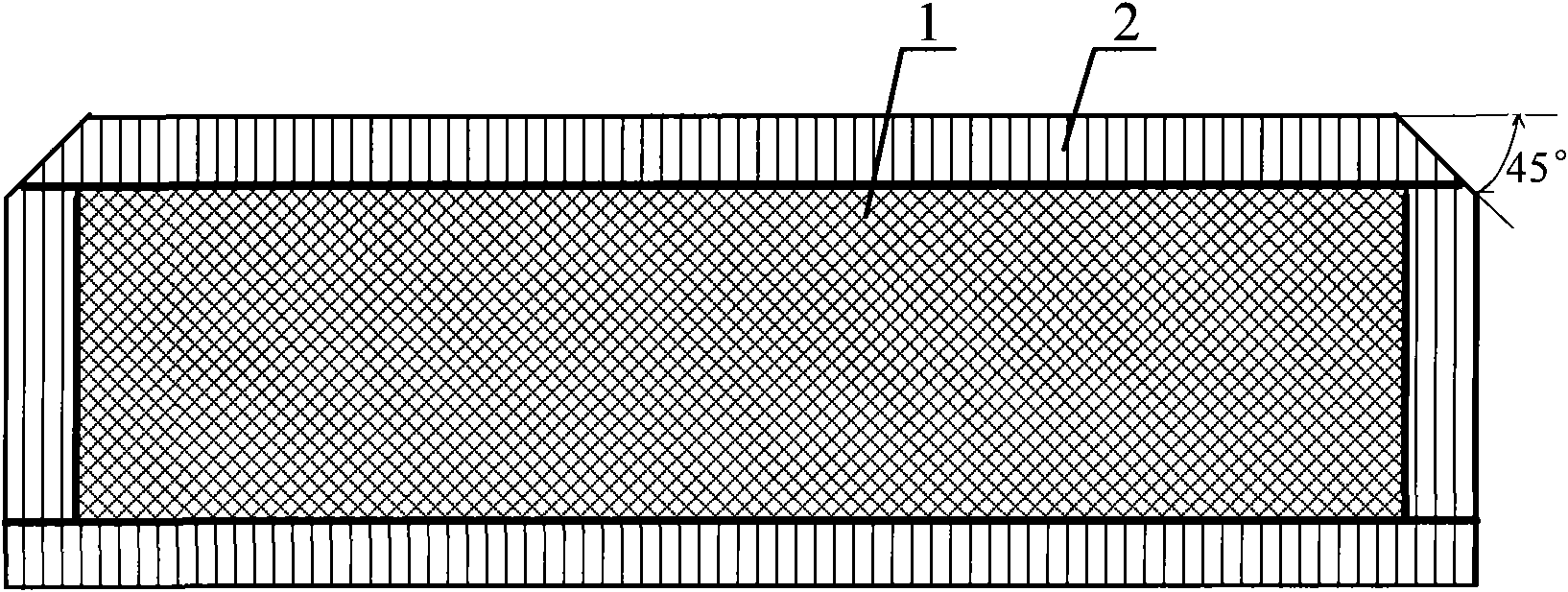

Novel acrylic splicing decorative panel and manufacturing process thereof

An acrylic board and acrylic technology, applied in the field of decorative materials, can solve the problems of improper use of furniture, poor waterproof and moisture-proof performance, and easy surface damage, and achieve the effect of increasing application fields, beautiful appearance and unique shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

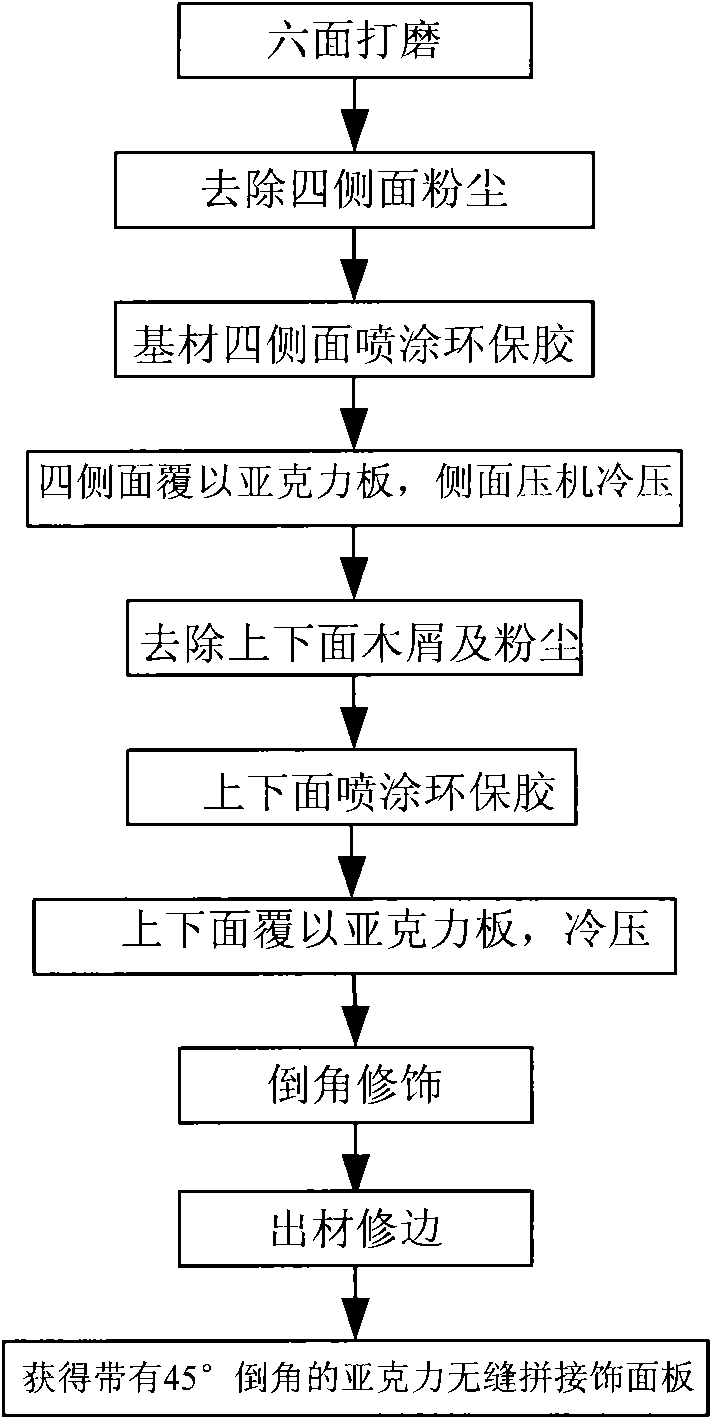

Embodiment 1

[0025] Select the density board as the substrate, and use sandpaper to regularly polish the six sides of the density board at least twice; brush off the dust on the front, back, left, and right sides of the density board; The side is sprayed with environmentally friendly spray glue, and the density board and acrylic board are sent to the side cold press for cold pressing. The pressing time is 3 minutes / batch, and the cold pressing pressure is 1.0MPa, so that the front, rear and left sides of the density board , The four right sides are all bonded with acrylic boards, and the heights of the front, back, left and right four acrylic boards are equal to the height of the density board; the dust on the upper and lower surfaces of the obtained boards is brushed off; the upper and lower surfaces of the above boards are coated with environmental protection Type spray glue, send the above board and acrylic board coated with environmentally friendly spray glue into the cold press machine...

Embodiment 2

[0027] Choose particleboard as the substrate, and use sandpaper to regularly polish the six sides of the particleboard at least twice; brush off the dust on the front, back, left, and right sides of the particleboard; spray environmental protection on the front, back, left, and right sides of the particleboard. Type spray glue, send the particle board and acrylic board into the side cold press machine, and carry out cold pressing. The pressing time is 2 minutes / batch, and the cold pressing pressure is 2.0MPa, so that the front, rear, left and right sides of the particle board are uniform Adhesive with acrylic boards, the height of the front, back, left and right four acrylic boards is equal to the height of the particleboard; brush off the dust on the upper and lower surfaces of the obtained boards; The above boards and acrylic boards with environmentally friendly spray glue are sent into the cold press machine, and the center line of the above boards and acrylic boards coincid...

Embodiment 3

[0029] Select the multi-layer board as the substrate, and use sandpaper to regularly polish the six sides of the multi-layer board at least twice; brush off the dust on the front, back, left, and right sides of the multi-layer board; The left and right sides are sprayed with environmentally friendly spray glue, and the multi-layer board and acrylic board are sent to the side cold press for cold pressing. The pressing time is 2 minutes / batch, and the cold pressing pressure is 1.5MPa, so that the multi-layer board Acrylic panels are bonded to the front, rear, left and right sides of the front, rear, left and right sides, and the height of the four acrylic panels is equal to the height of the multi-layer board; brush off the dust on the upper and lower surfaces of the board obtained; The upper and lower surfaces of the board are coated with environmentally-friendly spray glue, and the above-mentioned board and acrylic board coated with environmentally-friendly spray glue are sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com