Washer for conveying parts in turntable stepping mode

A step-by-step cleaning machine technology, applied in the field of cleaning machines, can solve the problems of large equipment footprint, complex equipment structure, and inconvenient daily maintenance, and achieve the effects of small footprint, reduced equipment volume, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

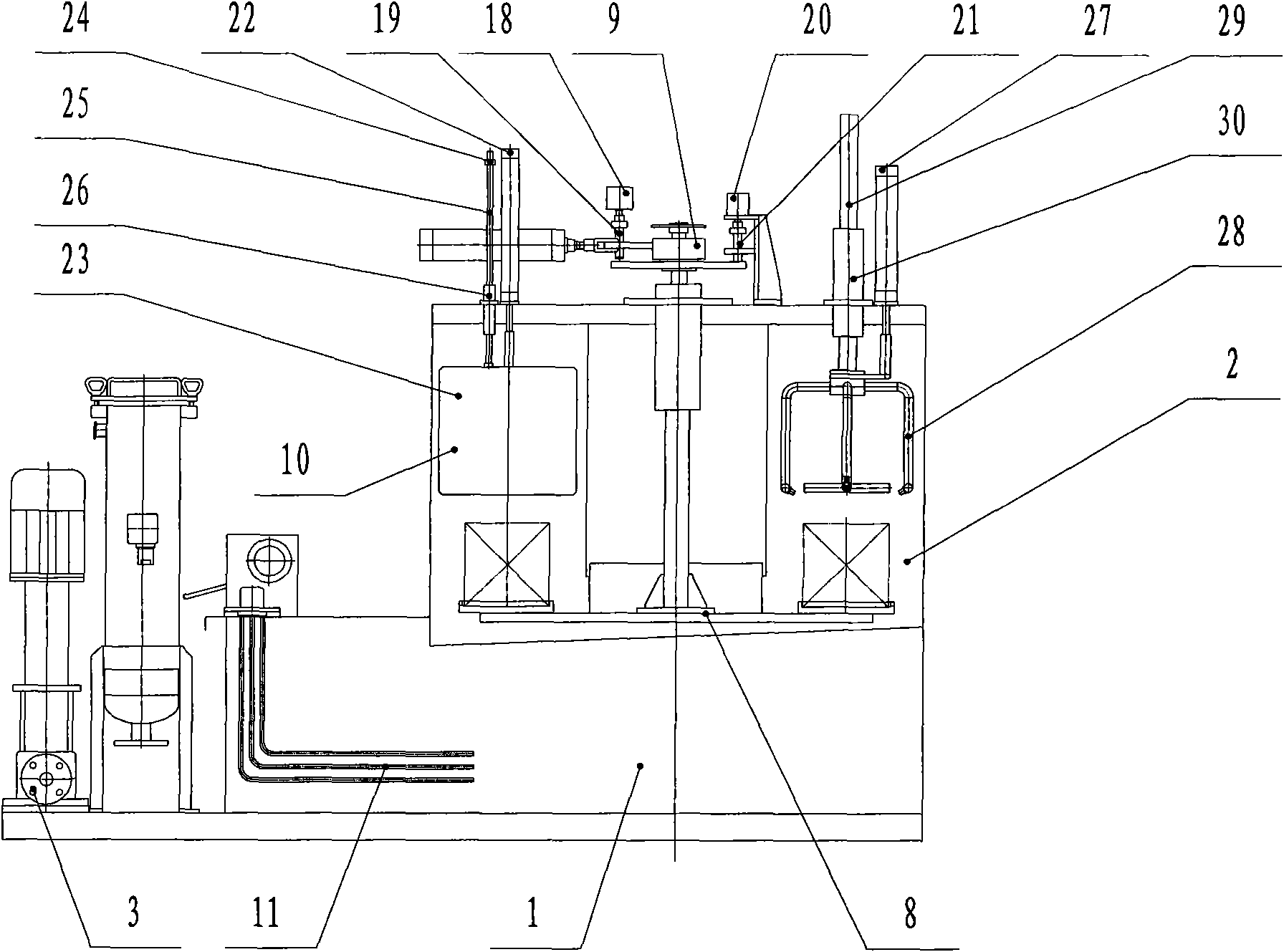

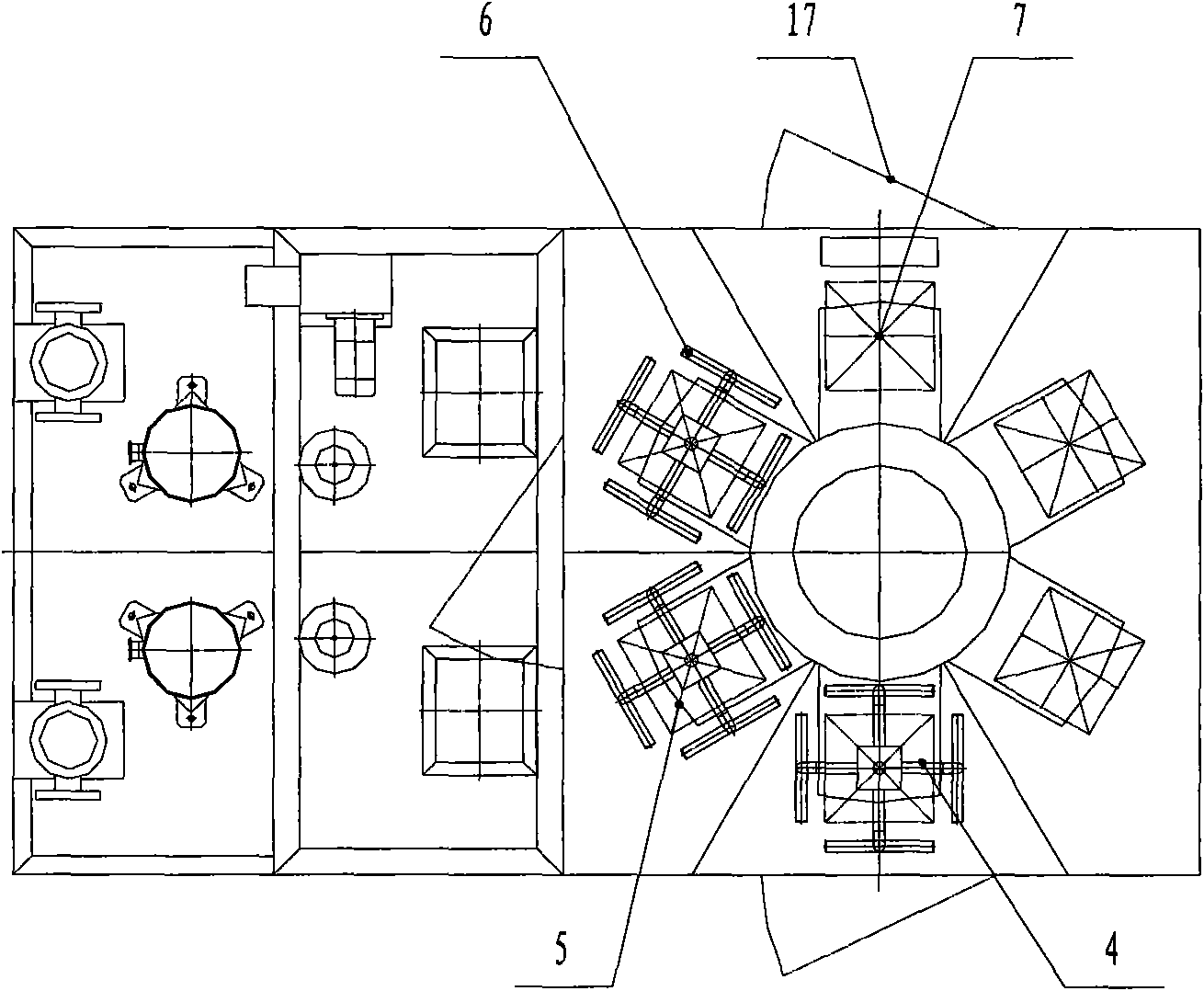

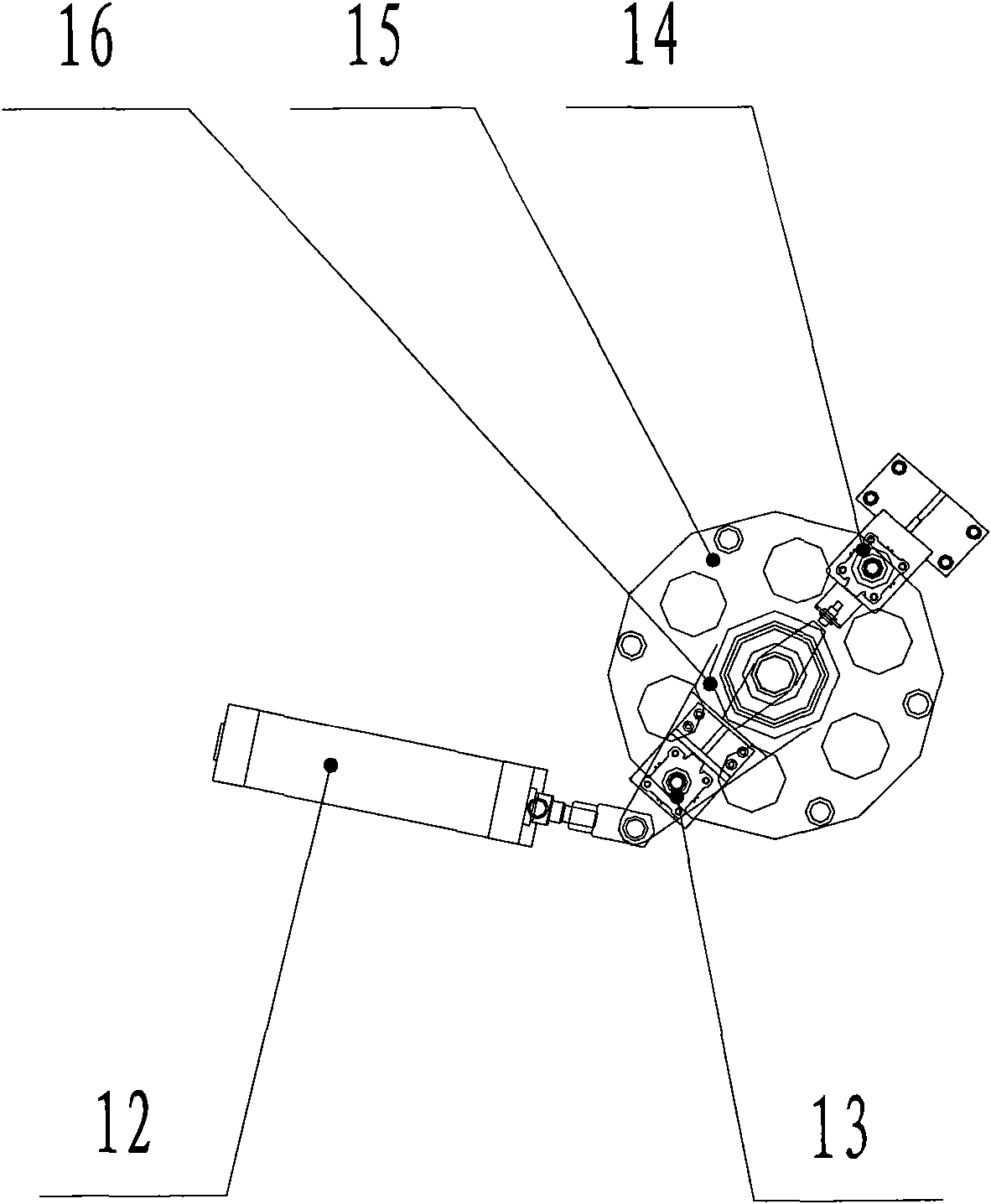

Embodiment 1

[0031] The driving device includes an electric motor, a pneumatic pump and a hydraulic pump, and the pneumatic pump is used as the driving device in this embodiment.

[0032] The parts are put into the feeding station in the working room body 2, the program controls the driving device 18 of the positioning bolt mechanism 13, that is, the pneumatic pump, and the stepping turntable 15 and the swing arm 16 are connected into one body through the bolt 19, and the stepping driving device 12 action, drive the swing arm 16 to rotate, push the stepping turntable 15 to rotate a station, the driving device 18 of the positioning latch mechanism 13 retracts, and the latch 19 retracts at the same time; the stop driving device 20 of the stop latch mechanism 14 stretches out, passes The stop bolt 21 fixes the stepping turntable 15, and the stepping drive 12 drives the swing arm 16 to get back to its original position during the return journey, so that the next working cycle can be started, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com