Blowing interface of blowing and sucking machine

A blower and interface technology, which is applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve the problems of plane cleaning before discomfort, heavy workload, cumbersome replacement and use, etc., and achieve effective It is beneficial to popularization and application, reduces production cost, and has the effects of simple and convenient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

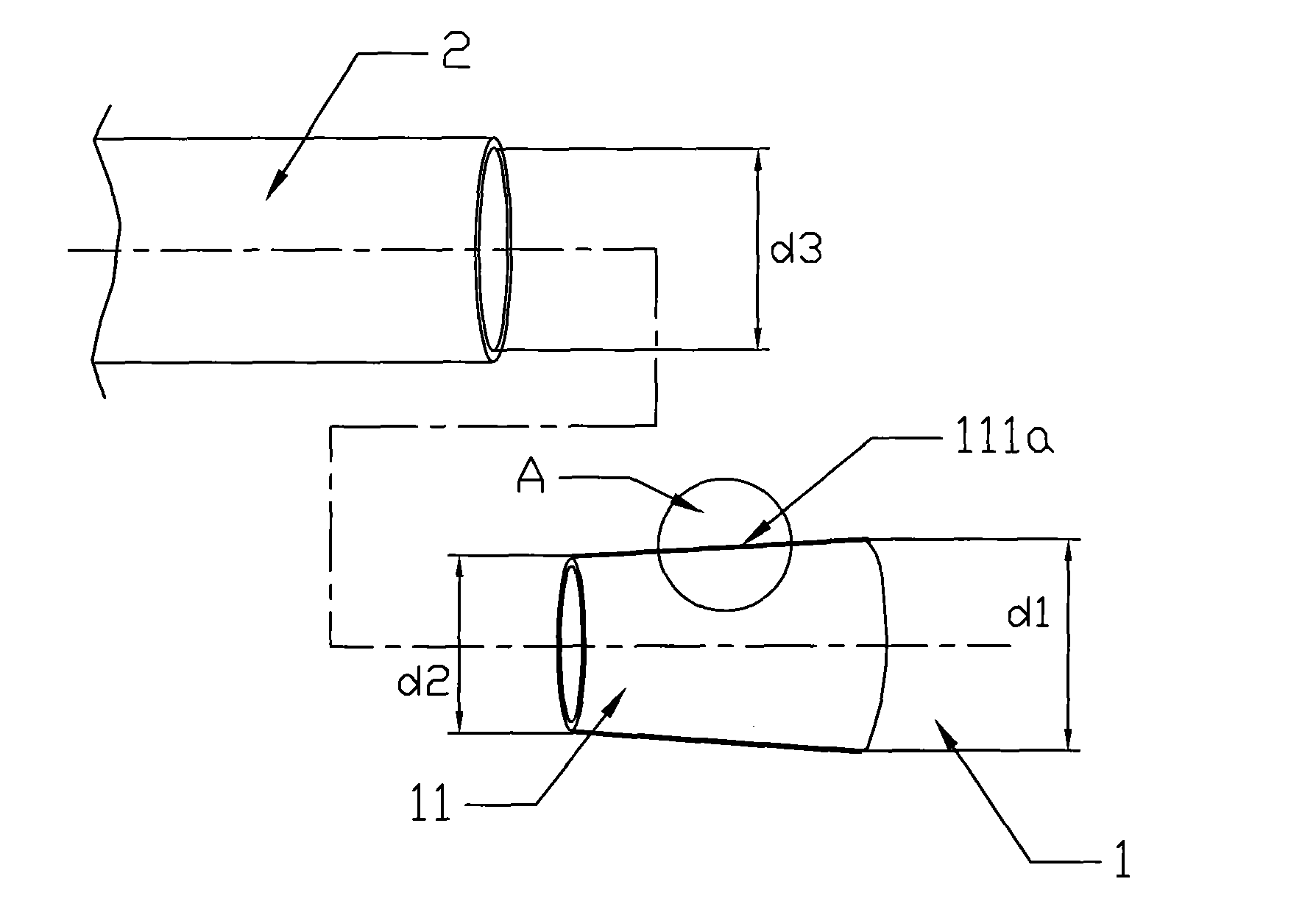

[0018] Such as figure 1 and Figure 1a As shown, the end of the exhaust pipe 1 of the blower is processed into a tapered pipe 11, that is, the outer diameter is tapered along the air outlet direction, and the diameter difference between the largest outer diameter d1 and the smallest outer diameter d2 is greater than 5mm. Moreover, the nozzle 2 of the extension pipe or blowing booster nozzle that is used to connect with the exhaust pipe 1 is designed to have no change in inner diameter, and its inner diameter d3 is between the maximum outer diameter d1 and the smallest outer diameter d2 of the tapered pipe. between.

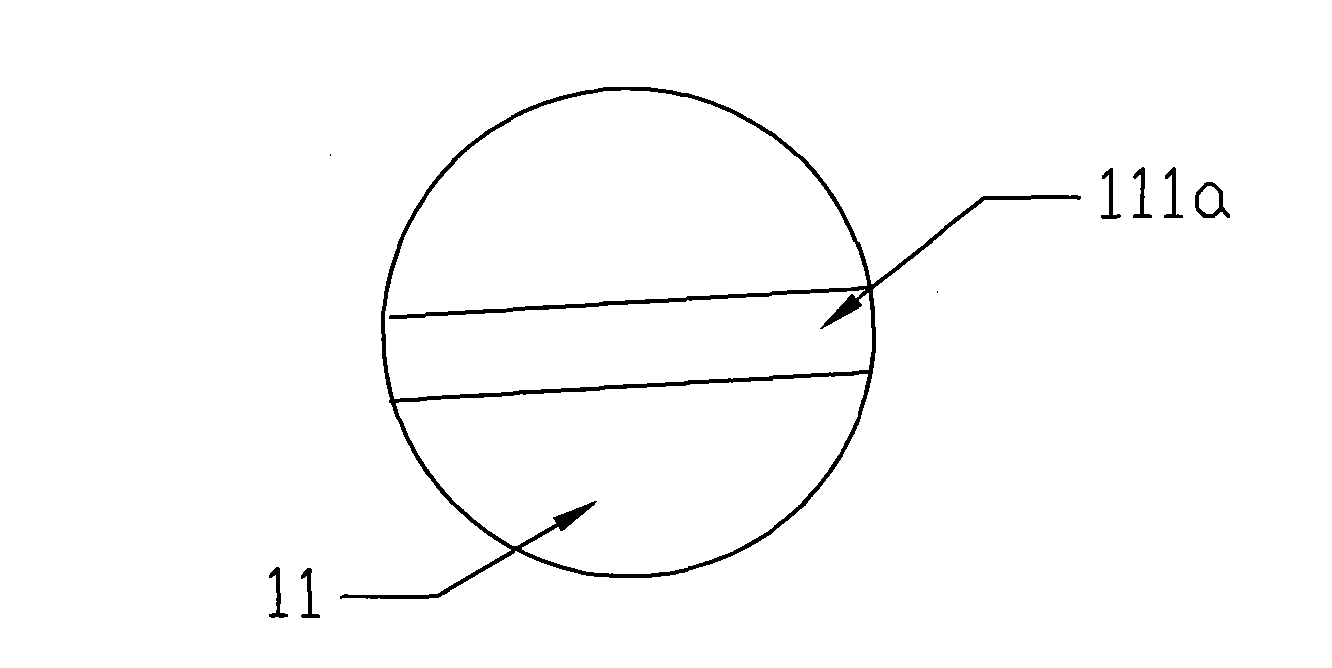

[0019] It can also be seen from the figure that the contact damping layer 111a of rubber material is distributed on the surface of the conical tube 11 of this embodiment with equal thickness, so that when the nozzle 2 is sleeved on the conical tube 11, the The contact damping layer 111a is tightly bonded, and even through a simple direct insertion method, the te...

Embodiment 2

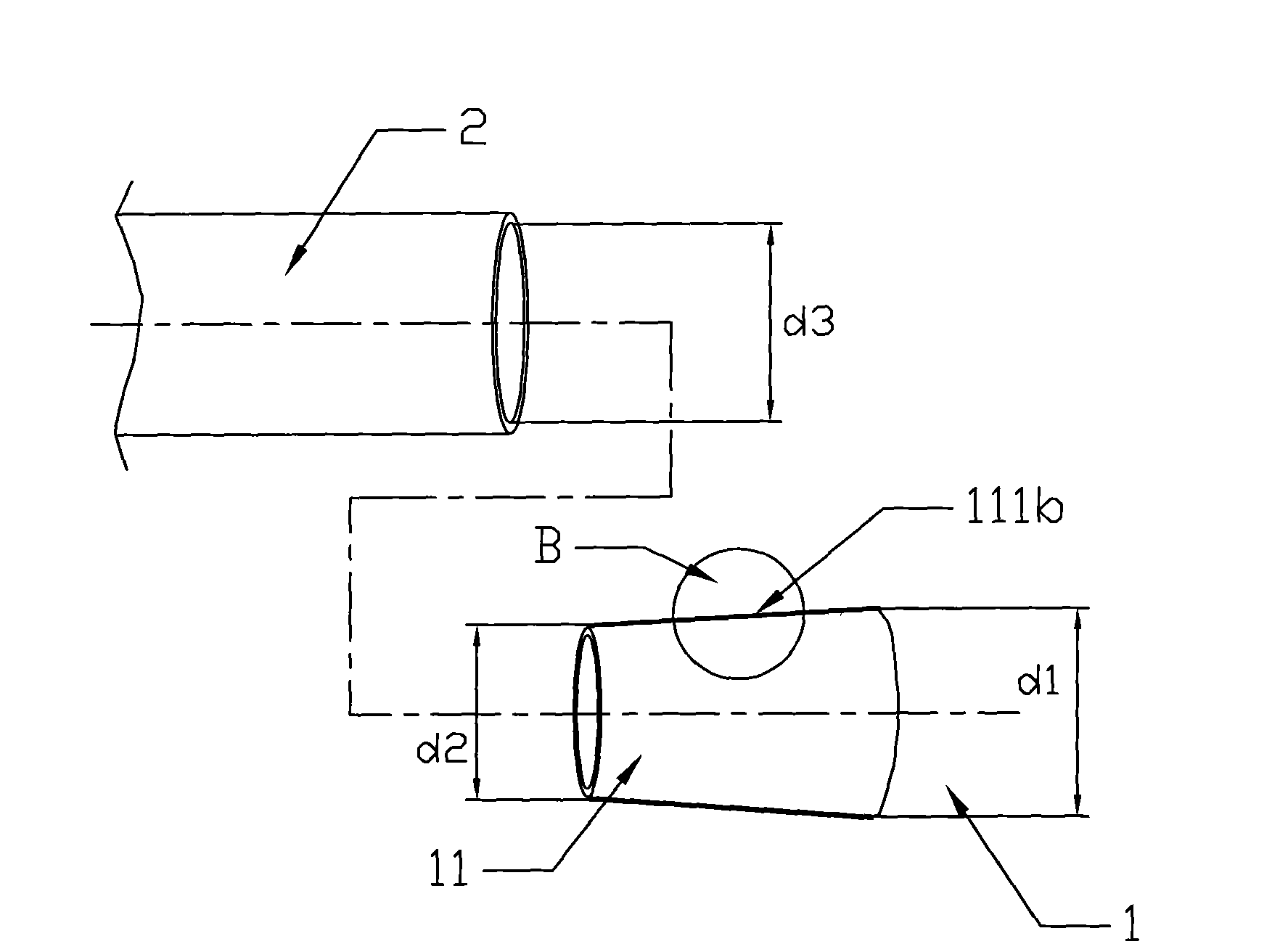

[0021] Such as figure 2 and Figure 2a As shown, the overall structure of this preferred embodiment is roughly the same as that of Embodiment 1, especially the characteristic structure is also processed into the form of a tapered pipe 11 at the end of the exhaust pipe, and the pipes of optional components are externally connected by means of direct insertion. Port 2, and the surface of the conical tube 11 is also distributed with a contact damping layer on the entire circumference. The difference is that the contact damping layer 111b made of polyester is designed to be non-uniform in thickness, and its thickness increases step by step as the outer diameter of the tapered tube 11 increases (d2→d1).

[0022] In this way, when the nozzle 2 is sleeved on the tapered tube 11, it can be sealed and fastened by the continuously thickened contact damping layer 111b, even through a simple direct plug-in method, a tight joint can still be obtained. The technical effect is high, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com