Method for preparing polyether-ether-ketone (PEEK) pipe

A technology of polyetheretherketone pipe and polyether ether ketone, which is applied in the field of preparation of pipes with polyether ether ketone as the main raw material, can solve the problems of wasting raw materials and processing costs, high height, wasting raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

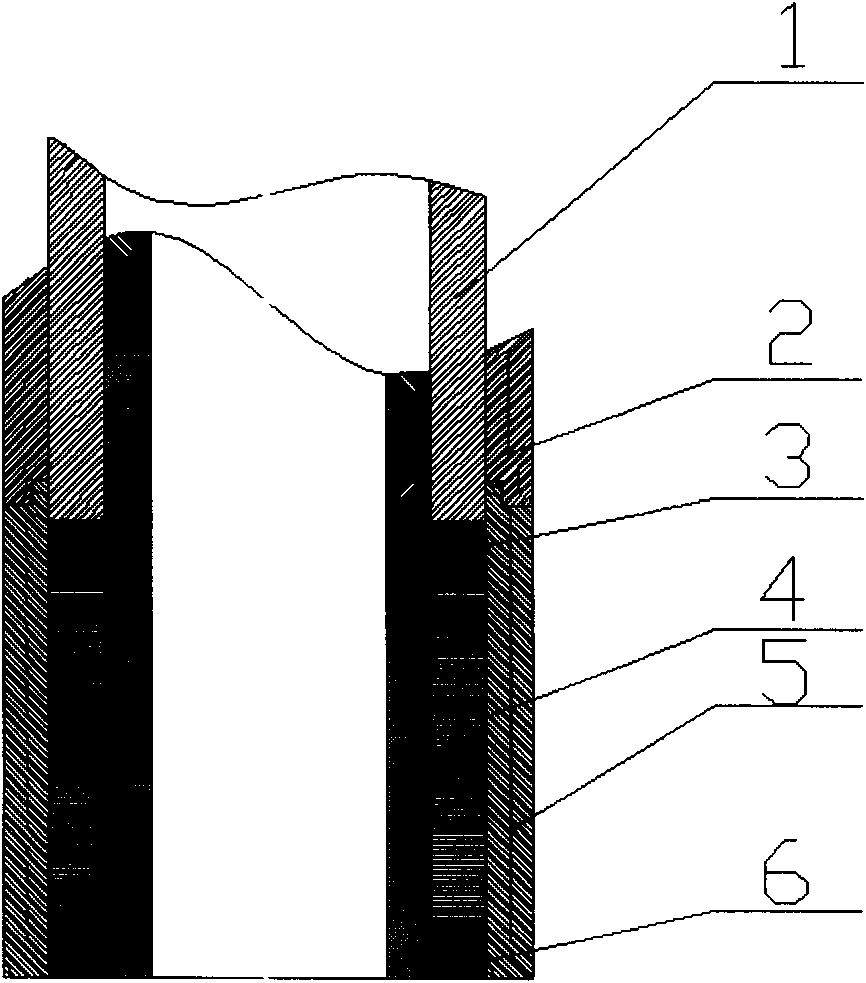

[0020] First get 1.8Kg of PEEK powder that has been baked for 4 hours and place it in the mold (see figure 1 ), pressurize to 15MPa on a 350-ton press, hold the pressure for 3 minutes, then remove the auxiliary feeding part, place the mold in a sintering furnace at 380°C for 8 hours, take out the mold and add it to the 350-ton press Press to 10MPa, cool for 40 minutes, demould when the temperature drops to 180°C, place the pipe in an oven at 200°C for heat treatment, and get a product of ¢260*210*80, which can be used to process bearings and gaskets , Seals, plating rings, piston rings, check rings, support rings, pump body or valve parts. Such products are mainly used to produce electroplating rings. This selective electroplating is a high-speed and economical electroplating method, which is suitable for electroplating lead frames of electronic components such as ICs, diodes, triodes, connectors, and LEDs. Due to the purposeful selective electroplating of the functional area...

Embodiment 2

[0022] First take 1.2KG of PEEK powder that has been baked for 4 hours and place it in the mold (see figure 1 ), pressurize to 20MPa on a 500-ton press, hold the pressure for 3 minutes, then remove the auxiliary feeding part, place the mold in a sintering furnace at 390°C for 8 hours, take out the mold and add it to the 500-ton press Press to 10MPa, cool for 40 minutes, demould when the temperature drops to 190°C, place the pipe in an oven at 240°C for heat treatment, and get a product with ¢200*175*80, which can be used to process bearings and gaskets , Seals, electroplated rings, piston rings, check rings, support rings, pump body or valve parts. A support ring of ¢198*178*10 can be produced with the blank of this specification.

Embodiment 3

[0024] First take 2KG of PEEK modified powder (PEEK+graphite+molybdenum disulfide+glass fiber+PTFE) that has been baked for 4 hours, and place it in the mold (see figure 1 ), pressurize to 18MPa on a 500-ton press, hold the pressure for 3 minutes, then remove the auxiliary feeding part, place the mold in a sintering furnace at 390°C for 10 hours, take out the mold and add it to the 500-ton press Press to 10MPa, cool for 40 minutes, demould when the temperature drops to 200°C, place the pipe in an oven at 260°C for heat treatment, and get a product with ¢260*210*85, which can be used to process bearings and gaskets , Seals, piston rings, check rings, support rings, pump body or valve parts.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap