Piston ring set used for natural gas engine

A technology for engines and piston rings, which is applied in the field of piston rings for natural gas engines, which can solve the problems of high exhaust temperature, poor lubrication effect, long processing technology of spiral spring oil rings, and difficulty in adapting to the requirements of low engine oil consumption. and other issues to achieve the effect of light weight, strong deformation ability and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings.

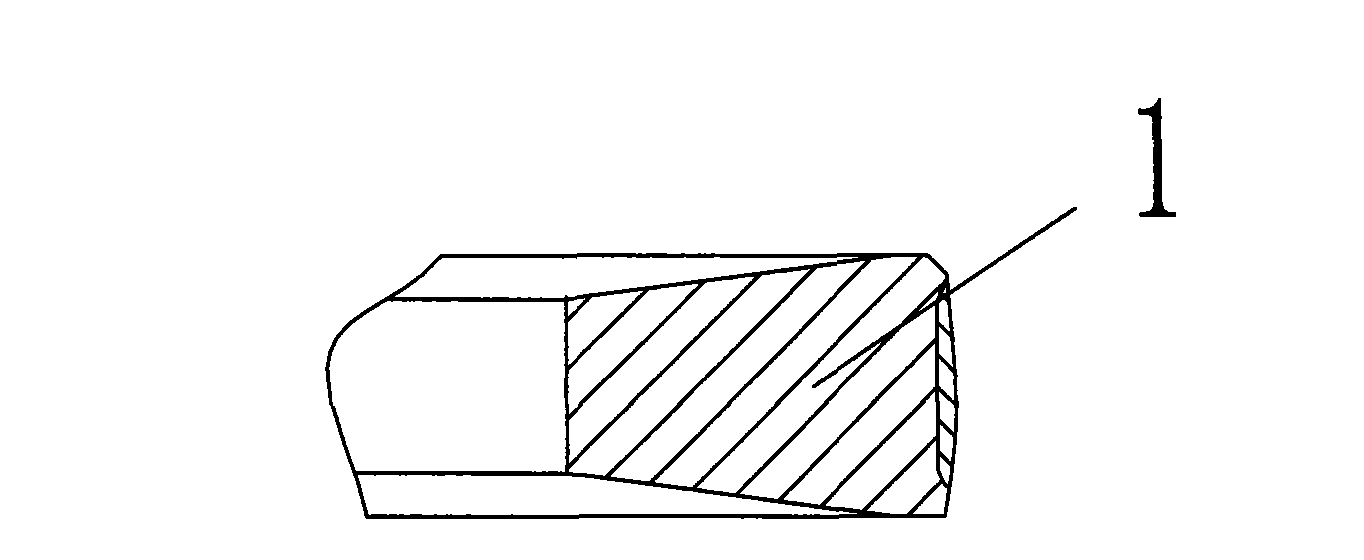

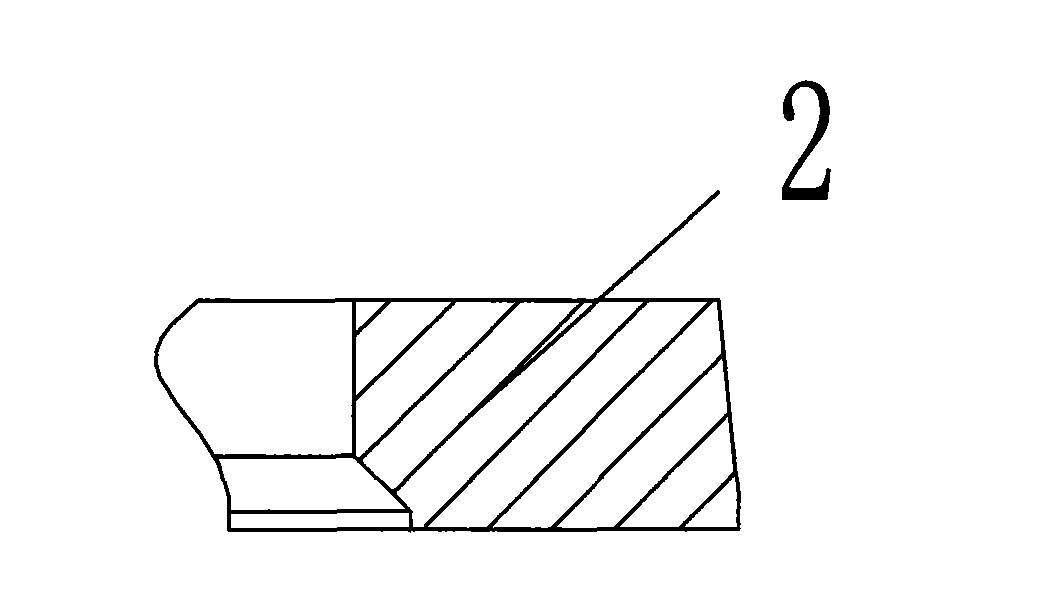

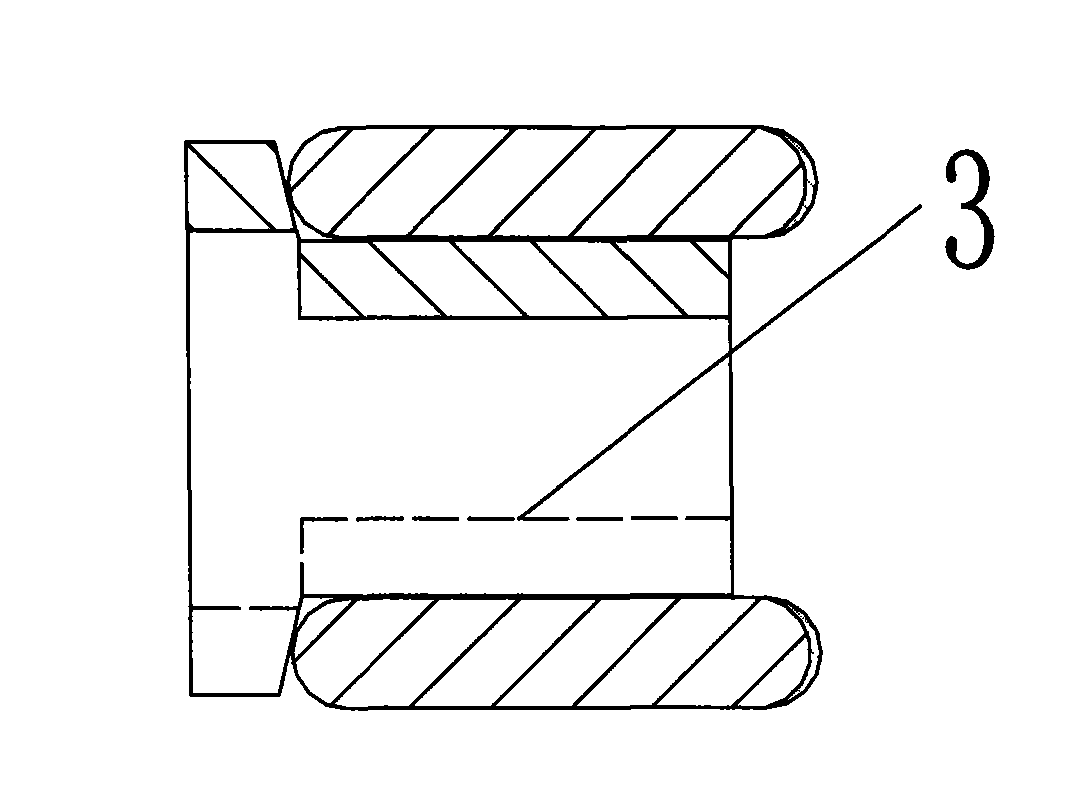

[0018] Such as Figure 1-a , Ren b and 1-c, the piston ring set of the present invention consists of two gas rings and one oil ring.

[0019] The design of the three-ring group comprehensively considers gas pressure, temperature, linear velocity of the piston assembly, and lubricating oil characteristics, and is functionally combined to ensure the sealing of high-temperature and high-pressure gas and the minimum lubricating oil film thickness.

[0020] The first air ring 1 adopts a double-ladder structure, and the surface is inlaid with molybdenum spraying treatment: the fine gaps in the molybdenum layer store lubricating oil to prevent fusion wear and cylinder scuffing in high temperature environments. The selection of air ring surface treatment must ensure long-lasting wear resistance and cylinder resistance, so the surface treatment layer is required to have good se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com