Hydrostatic and hydrodynamic combined type three-stage mechanical seal device for nuclear main pump

A mechanical seal device and mechanical seal technology are applied to parts of pumping devices for elastic fluids, liquid fuel engines, mechanical equipment, etc., which can solve problems such as the inability to establish fluid dynamic pressure effects and friction and wear of sealing surfaces, and achieve Good lubricating effect on the end face, leakage control, and uniform pressure distribution in the end face flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

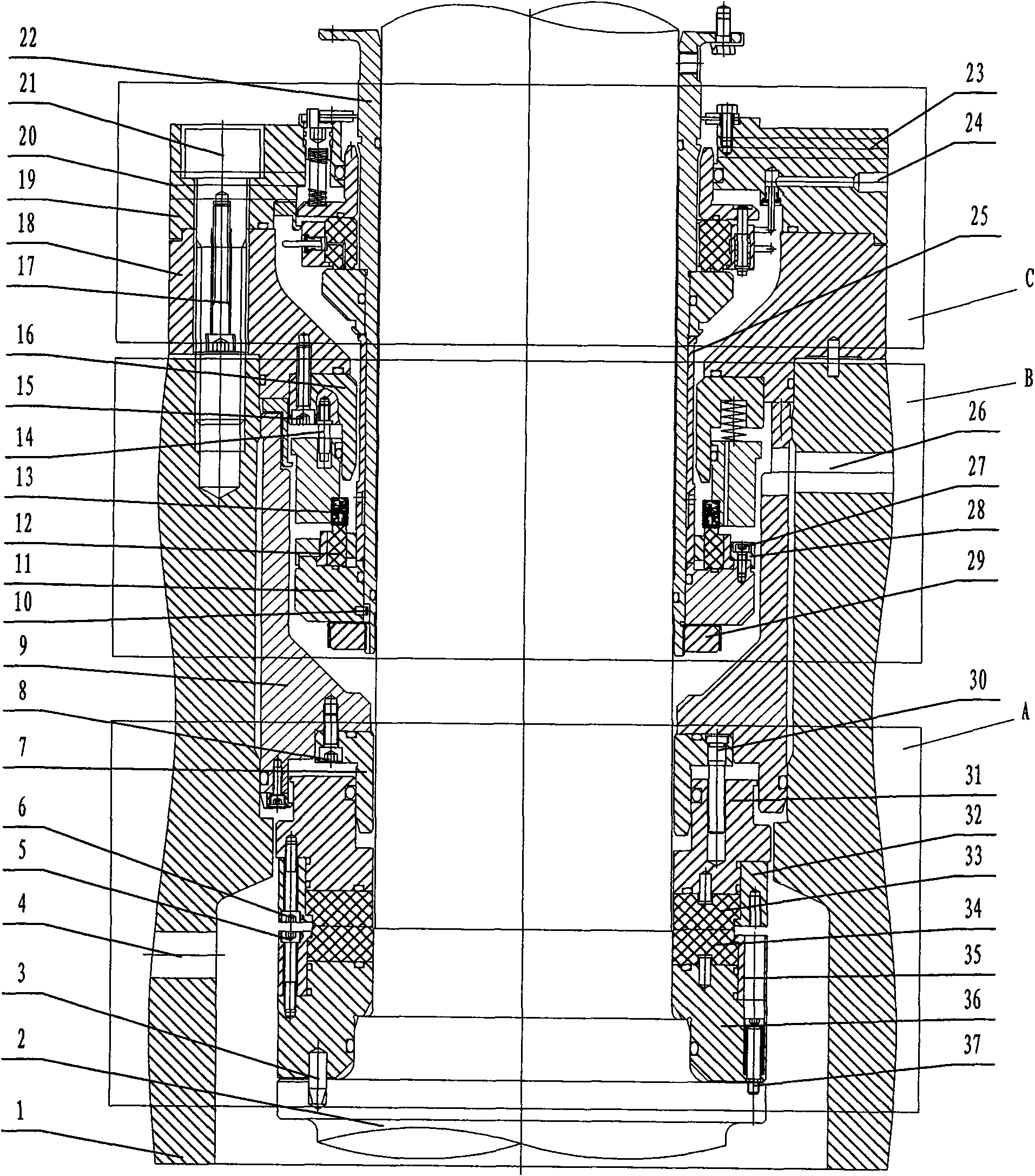

[0021] see figure 2 In this embodiment, three stages of mechanical seals are arranged in sequence along the pump shaft 2 from bottom to top. The first stage seal A is a hydrostatic mechanical seal, the second stage seal B is a hydrodynamic mechanical seal, and the third stage seal C is a contact mechanical seal.

[0022] The structure of the first level seal A is set as:

[0023] The first-stage sealing moving ring 34 and the first-stage moving ring seat 36 are sealed and fixed through the first-stage moving ring gland 35 and the first-stage moving ring gland screw 5, and the first-stage sealing moving ring seat 36 is sealed and fixed through the first-stage moving ring seat 36. The connecting screw 37 of the moving ring seat is sealed and firmly connected with the pump shaft 2, and the torque is transmitted through the transmission pin 3; The static ring gland screw 6 is sealed and fixed, the first stage static ring seat 31 is sealed and connected with the first stage bala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com