Processing method of prestress butt-joint precision mechanical steel guide rail

A technology of precision machinery and processing methods, applied in the field of prestressed butt joint precision mechanical steel guide rails and its processing, to achieve the effects of improved bearing capacity, good assembly process, and high butt joint accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

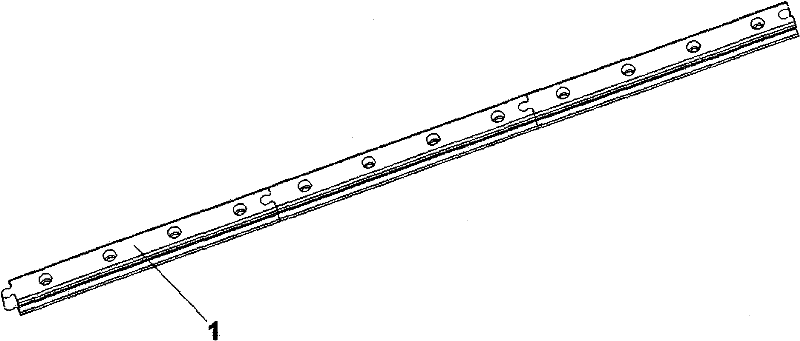

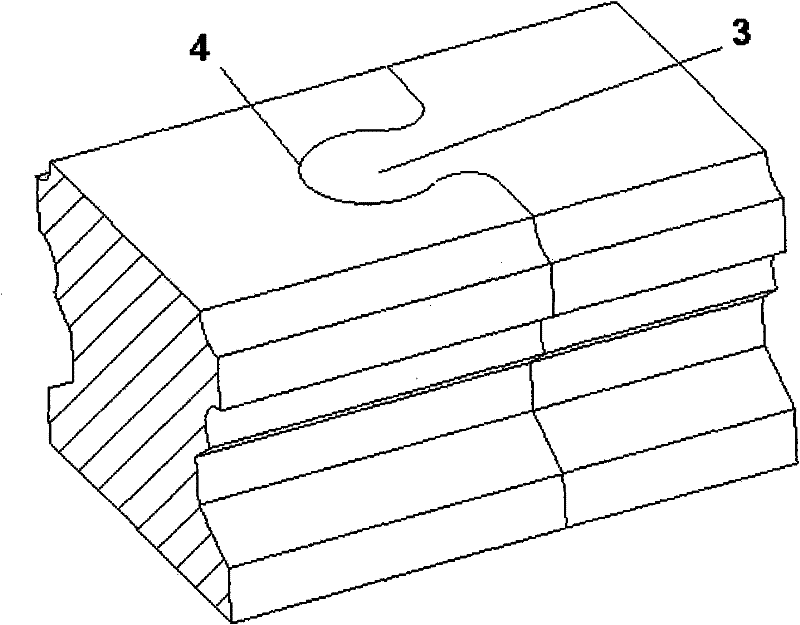

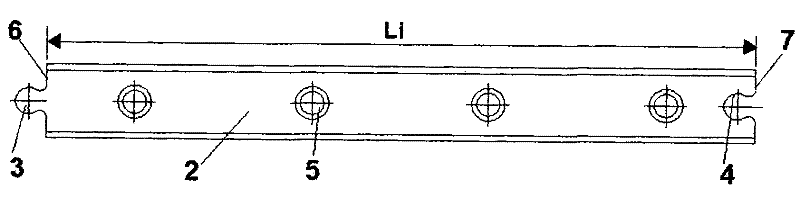

[0045] figure 1 It is a schematic diagram of the embodiment of the prestressed butt joint precision mechanical steel guide rail of the present invention. figure 2 It is a three-dimensional view of the partial structure of the joint of the embodiment of the prestressed butt joint precision mechanical steel guide rail of the present invention. image 3 It is a schematic diagram of the structural appearance of the embodiment of the butt steel guide rail section of the present invention. Figure 4 It is a structural cross-sectional schematic diagram of the embodiment of the butt steel guide rail section of the present invention. Figure 5 It is a schematic diagram of tenon structure parameters of the embodiment of the butt steel guide rail section of the present invention. Figure 6 It is a schematic diagram of the modified tongue and groove st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com