Nondestructive examination device and method of crack defects of inner surface of underground foundation embedded section of electric pole

A non-destructive testing, inner surface technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of heavy workload, surface crack defect detection, inconvenient operation, etc., to achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

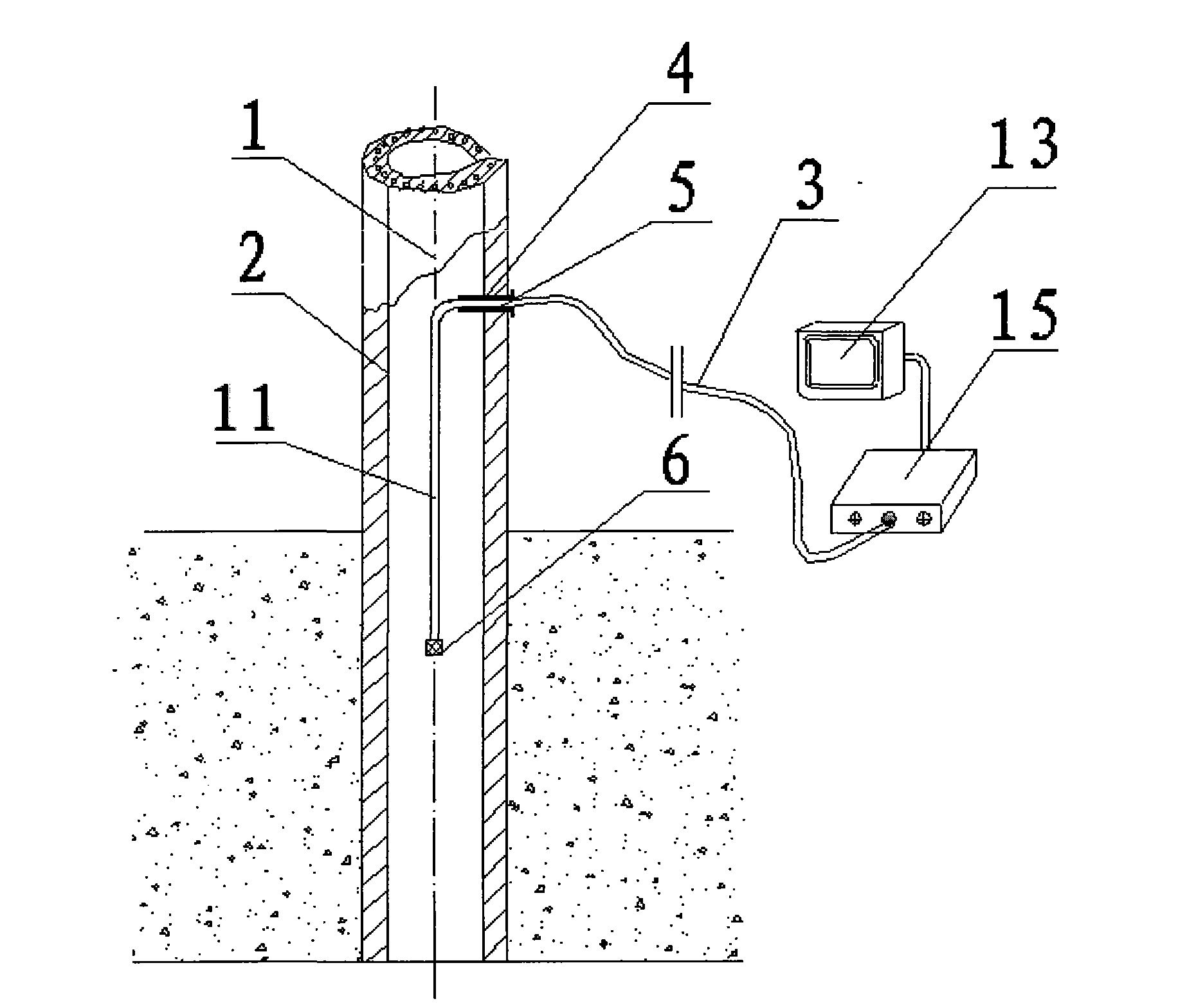

[0062] The device and method for non-destructive detection of cracks on the inner surface of the buried section of the underground foundation of the electric pole of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0063] See figure 1 with 4 The device for non-destructive detection of cracks on the inner surface of the buried deep section of the electric pole underground foundation of the present invention is composed of a supporting sleeve 5 and an endoscope system 3. The endoscope system 3 is composed of an endoscope probe 6, a signal line 10, a flexible hose 11, an external controller 12, a video monitor 13, a connector 14, and a computer 15. The endoscope probe 6 is composed of an objective lens 16, a light source 17. It is composed of a CCD camera 18, and the flexible hose 11 is connected to an external power source and a computer 15 through a connector 14.

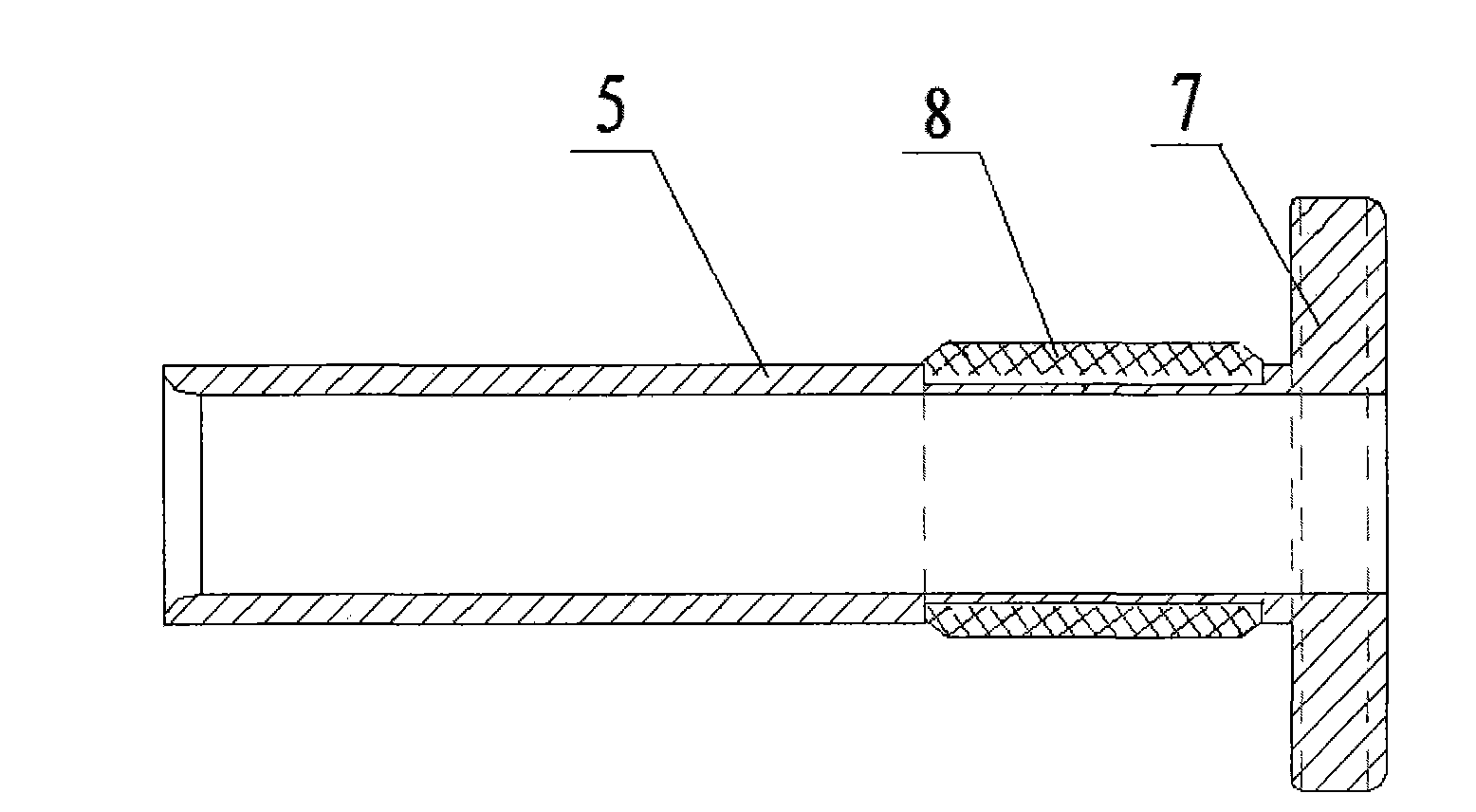

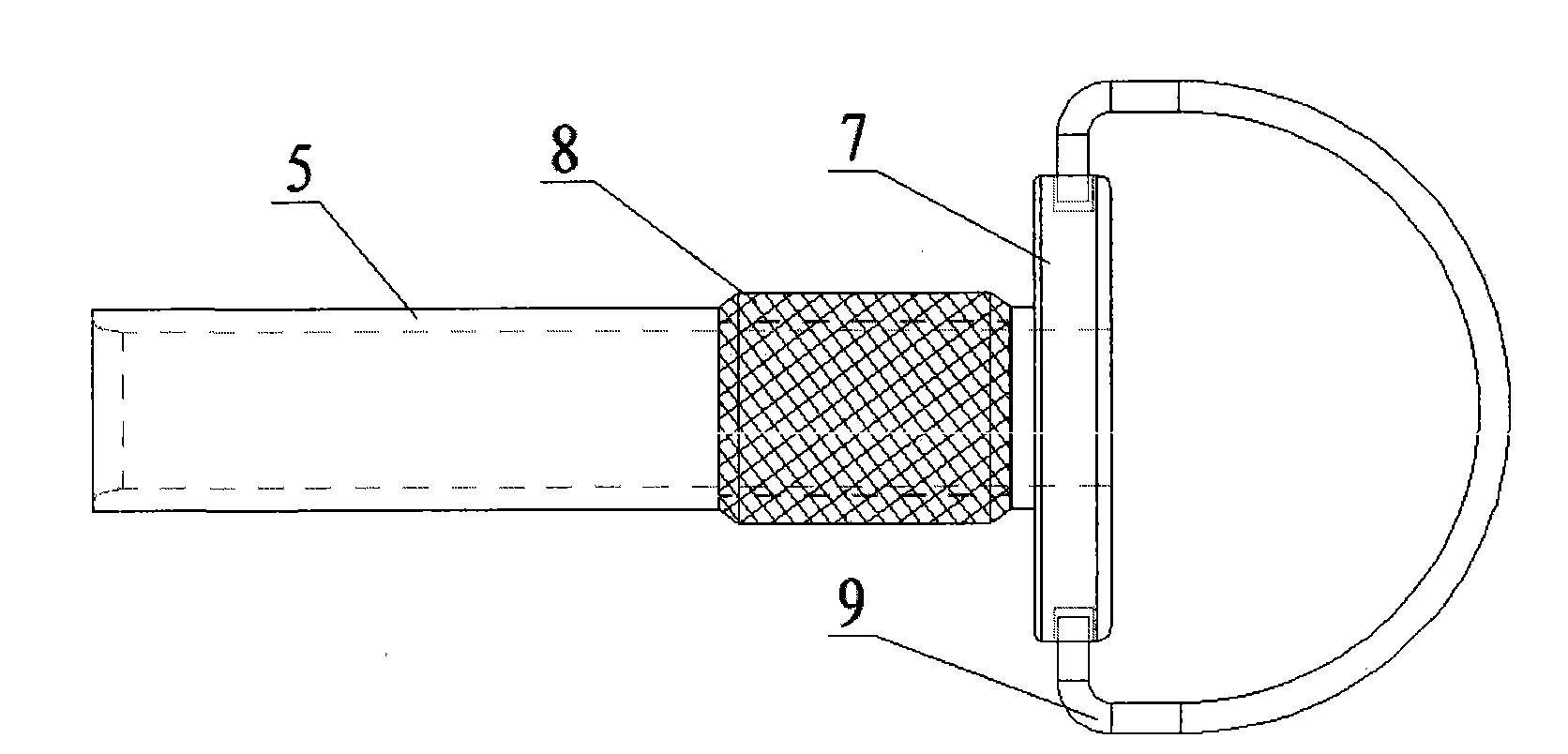

[0064] See figure 2 The support sleeve 5 has a cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com