Crush type grid

A crushing grid and blade technology, which is applied in waterway systems, drainage structures, grain processing, etc., can solve the problems of reducing the performance of the water pump, the life of the impeller of the pump, reducing the water efficiency of the grid, and affecting the performance of the grid. Cost, unlimited visual space, beautification of the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

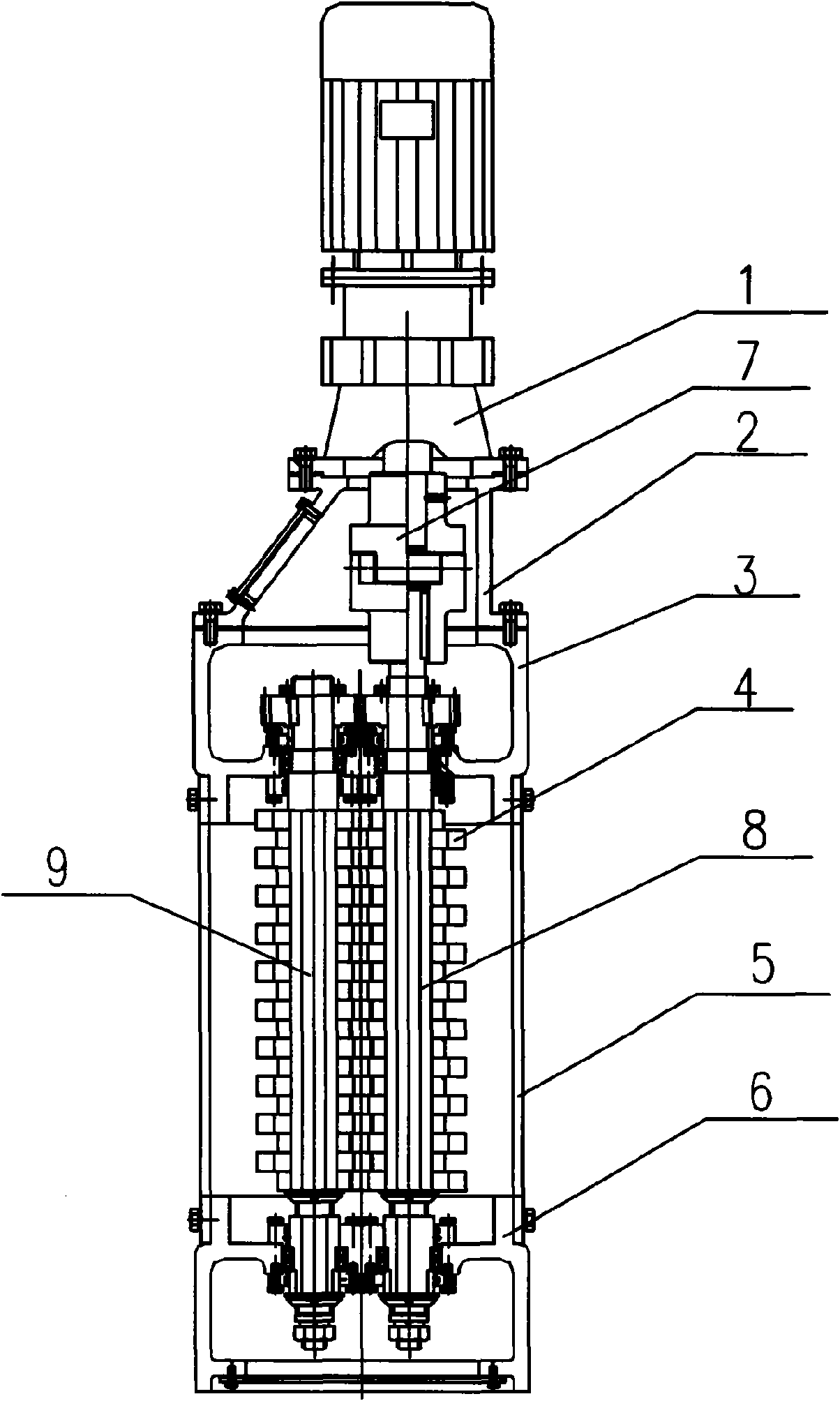

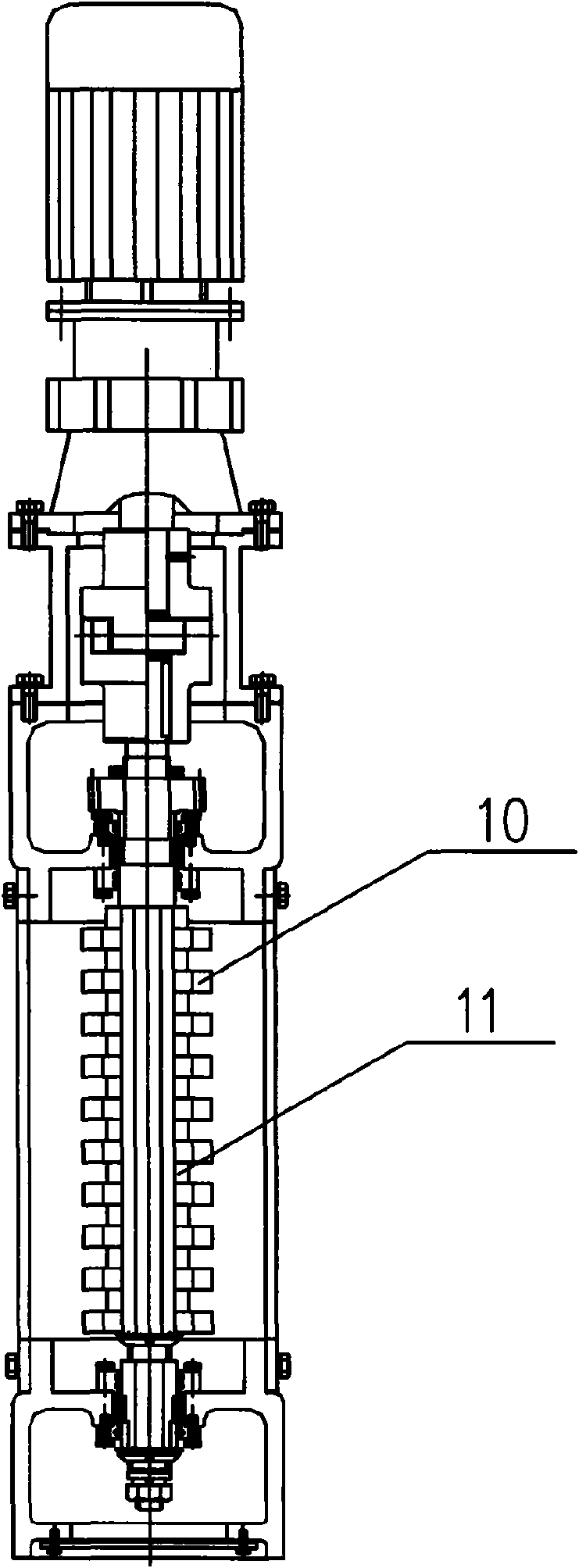

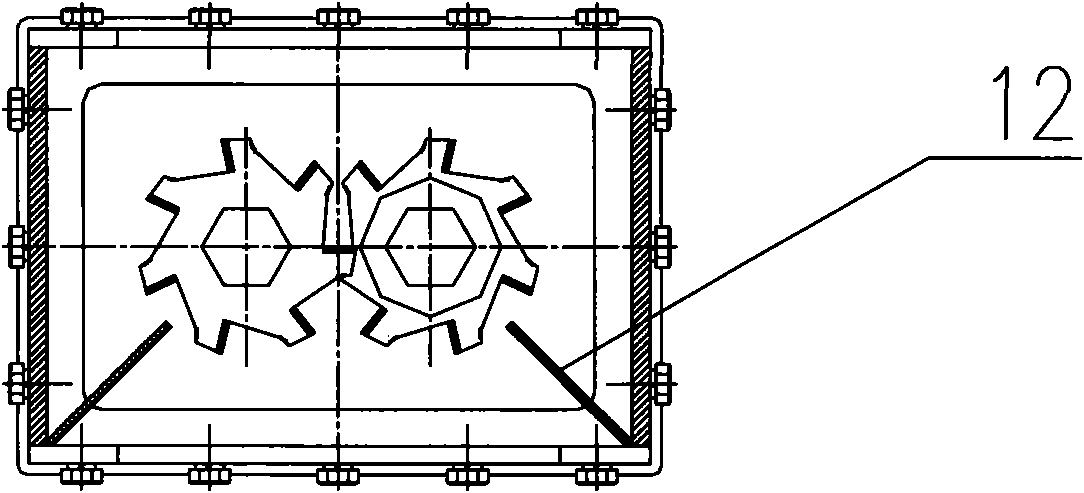

[0031] Such as Figure 1-Figure 3 As shown, the crushed grille of the present invention mainly includes a geared motor 1, a coupling box 2, a transmission shaft box 3, a guide bracket 5, and a tail box 6, from top to bottom, and each component is vertically installed in sequence. among them:

[0032] The output shaft of the reduction motor 1 is connected to the upper end of the driving shaft 8 through a coupling 7; the driven shaft 9 and the driving shaft 8 are arranged in parallel, and the upper and lower ends of the two are respectively supported by the transmission shaft box 3 and the tail box through bearings 6, and the middle part passes through the entire diversion bracket 5, the front and rear sides of the diversion bracket 5 have diversion openings, and the two sides of the diversion opening are provided with guide plates 12 inward. The driven shaft 9 and the driving shaft 8 are connected by a transmission mechanism, and the coupling-type tool assembly 4 is respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com