Railway traction locomotive dual-axis bogie

A railway traction and bogie technology, applied in the direction of self-adjustment of wheel axles, etc., can solve problems that have not yet been applied, and achieve the effects of improving curve guiding performance, enhancing running stability, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

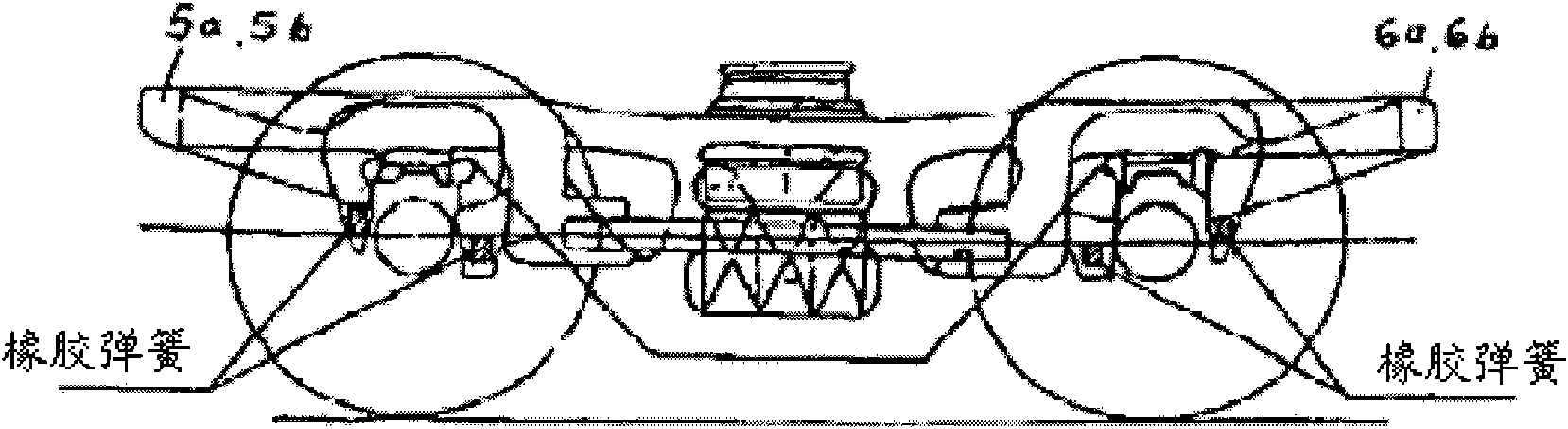

[0036] see Image 6 , 7 As shown, the technical solution provided in this embodiment is applied to a Y25 bogie.

[0037] One free arm of the L-shaped size adjuster 3 has an eyelet 5 to which the first pull rod 4 and / or the second pull rod 7 is connected, while the other free arm of the L-shaped size adjuster 3 is connected to the axle box luggage rack 2 on.

[0038] The axle box luggage rack 2 is an integral part of the axle box 1, which is connected to the axle box 1 by welding. Alternatively, the axle box luggage rack 2 is connected to the axle box 1 by means of screw connection. Alternatively, the axle box luggage rack 2 is cast integrally with the axle box 1 as a component of the axle box 1 .

[0039] Based on the size adaptor 3 is firmly connected to the axle box luggage rack 2 by means of threads. Alternatively, the size adjuster 3 and the axle box rack 2 can be connected by pins or as castings, then the axle box 1 is a single piece including the axle box rack 2 and...

Embodiment 2

[0047] see Figure 8 , 9 As shown, as in the first embodiment, the technical solution provided in this embodiment is applied to the Y25 bogie.

[0048] The L-shaped size adjuster 3 is connected to the axle box luggage rack 2, wherein the bottom short arm and the long free arm of the size adjuster 3 together with the holes 5 are connected to the first pull rod 4 (or the second pull rod 7) to form an L-shaped, short The arm is the base of the sizer 3.

[0049] The axle box luggage rack 2 is a constituent part of the axle box 1 . The axle box luggage rack 2 can be connected with the axle box 1 by welding. Alternatively, the axle box luggage rack 2 is connected to the axle box 1 by means of screw connection. Alternatively, the axle box luggage rack 2 is cast integrally with the axle box 1 as a component of the axle box 1 .

[0050] The arm of the size adjuster 3 is firmly connected to the axle box luggage rack 2 by means of a screw connection. Alternatively, the connection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com