Cooling outer wall structure of building and molding method thereof

A technology for building exterior walls and walls, applied to building components, building structures, buildings, etc., can solve problems such as limited heat insulation, complicated construction technology, unpopularity, etc., and achieve low cost, good economy and society Benefits, the effect of saving air-conditioning electricity bills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

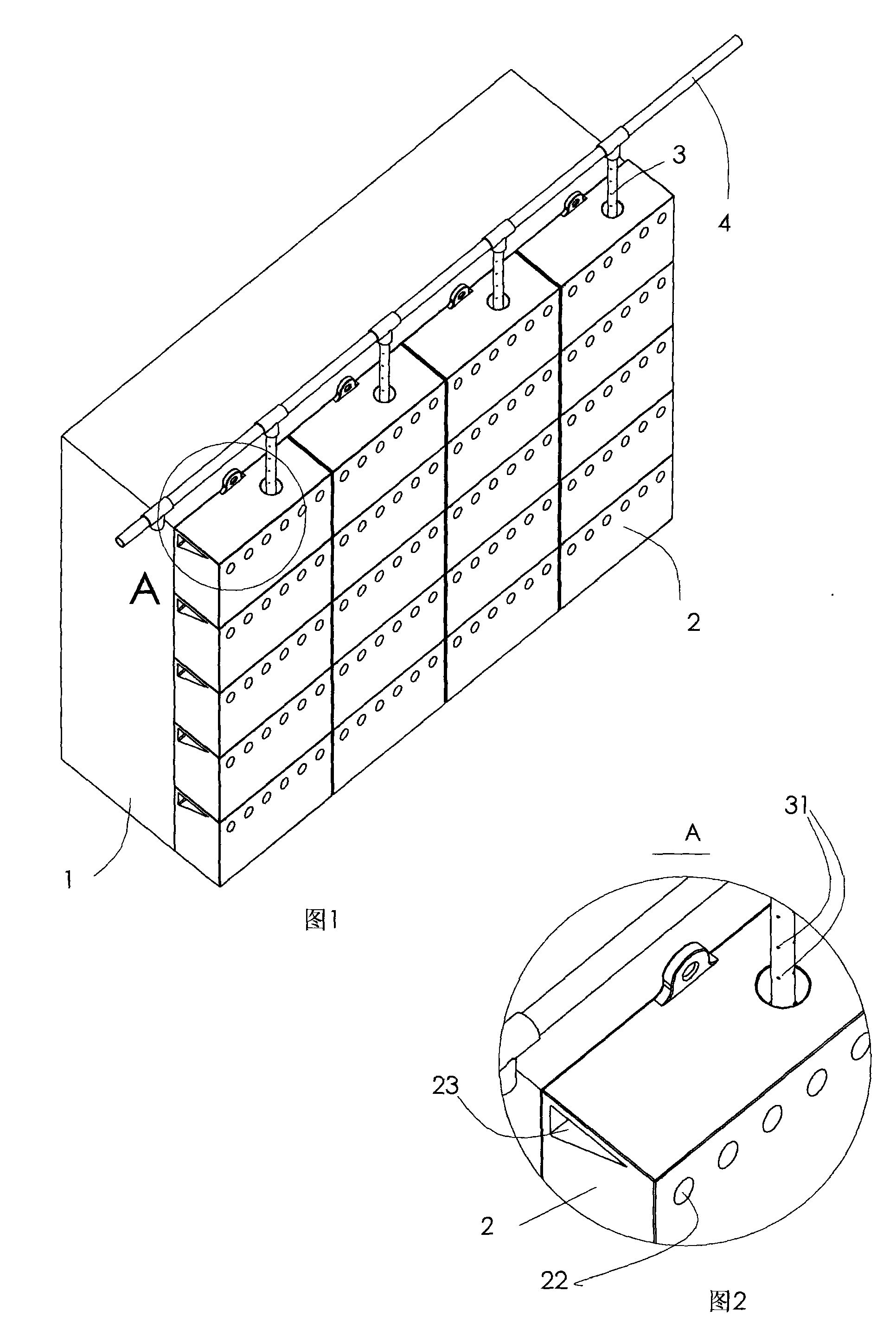

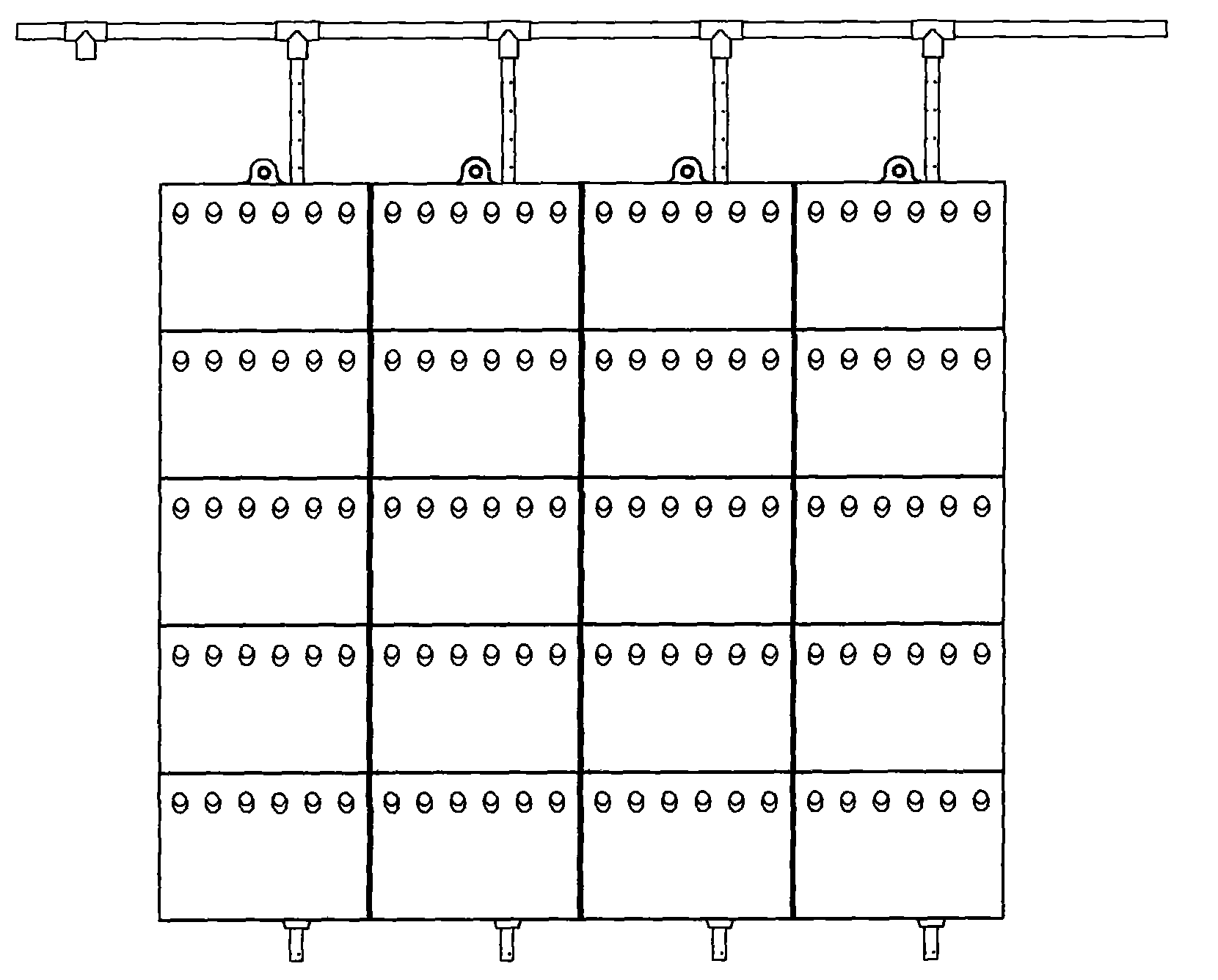

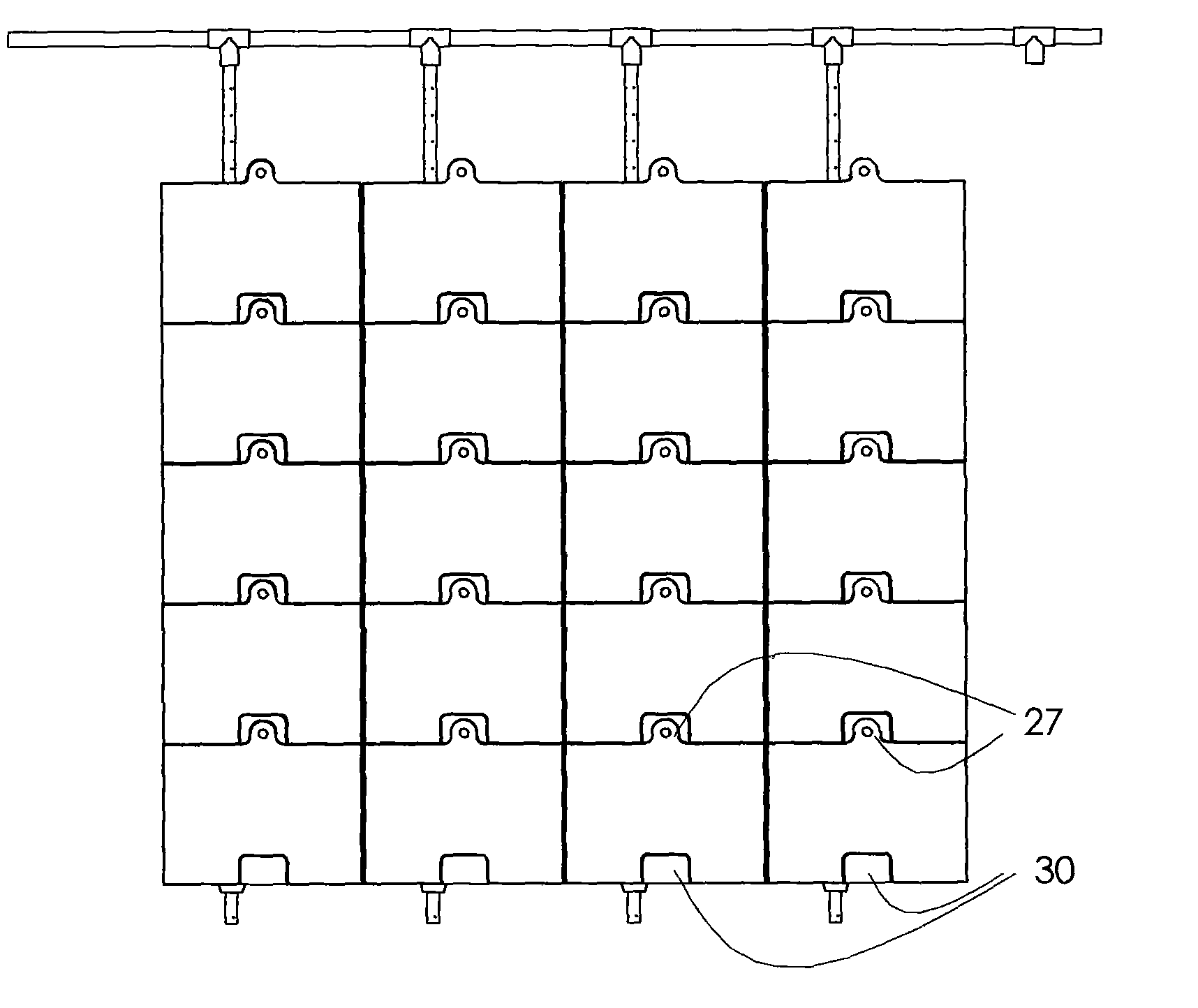

[0017] The cooling building exterior wall structure of the present invention is realized in this way: a cooling tile 2 and a drip irrigation pipe 3 are arranged outside the outer wall body 1, and the cooling tile is provided with an inner cavity 21, an air hole 22, an insulating cavity 23, an upper perforation 24 and The lower perforation 25 is provided with a mud material 26 in the inner cavity. The air holes 22 and the insulating cavity 23 are arranged on the mud material 26 . The drip irrigation pipe 3 is provided with several drip irrigation holes 31 . The drip irrigation pipe 3 runs through the upper perforation 24 and the lower perforation 25 of the cooling tile, and one end is connected with the water source pipe 4 (the water source can be non-potable water, if a pool is built on the roof, the water source pipe can be connected from the pool. The water source pipe is connected to the tap water). When the outdoor temperature increased, the moisture in the mud material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com