Method for manufacturing annular test-piece from cylindrical rock-soil material sample

A technology of geotechnical materials and cylindrical shape, which is applied in the field of preparing ring-shaped test pieces, can solve problems such as unstable clamping, difficult sampling methods, and damage to the structure of test pieces, and achieves convenient operation, high economic value and application value , The effect of simple method steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

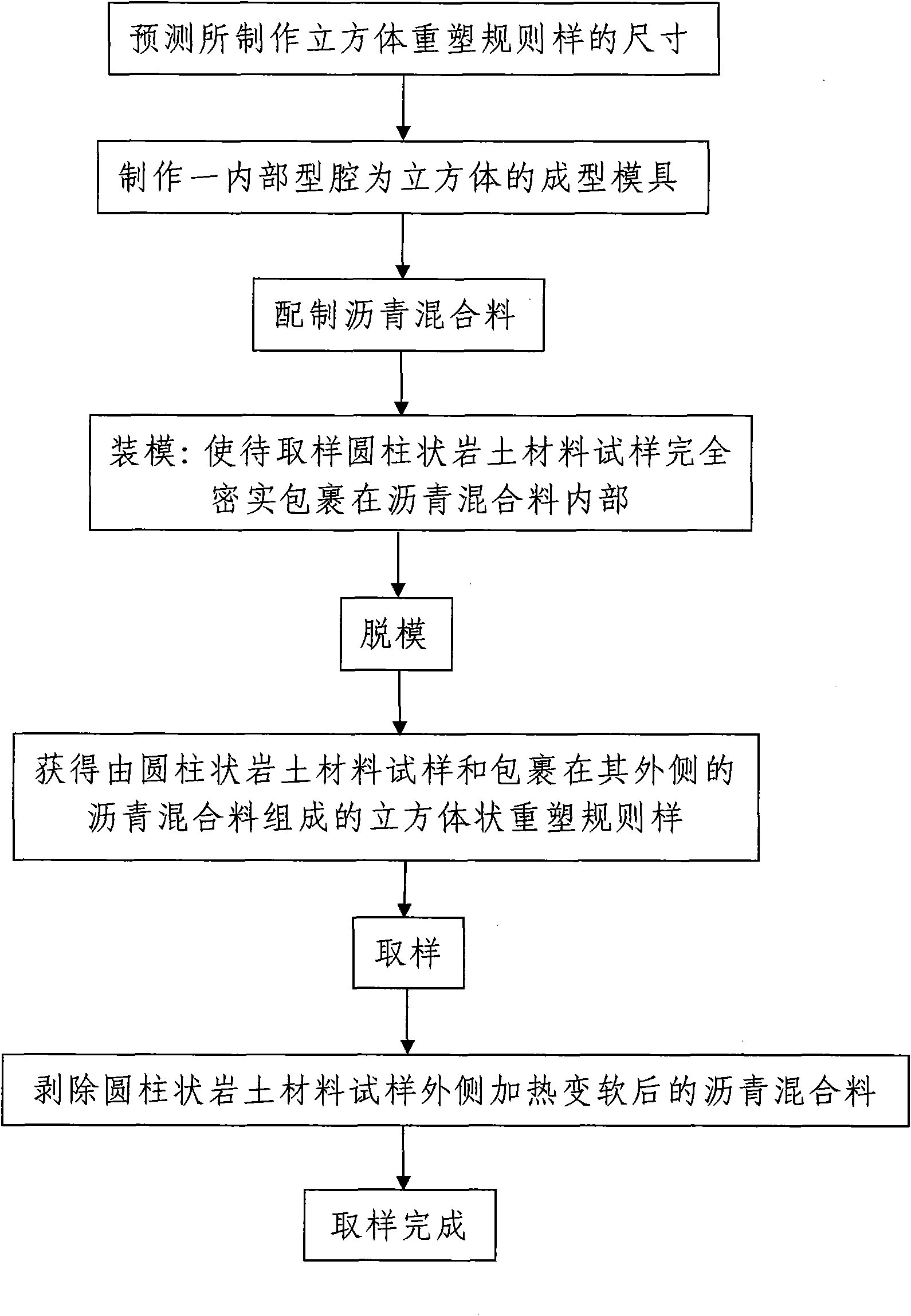

[0036] Such as figure 1 Shown, a kind of sampling method of making annular test piece from cylindrical geotechnical material sample of the present invention, comprises the following steps:

[0037] Step 1. Make a regular shape of the cube. The making process includes the following steps:

[0038] 101. According to the model size of the sampling rig used and the structure and size of the cylindrical geotechnical material sample to be sampled, predict and determine the size of the cubic remodeling regular sample made. The length, width and height of the remodeling regular sample are all different. less than the length, width and height of the cylindrical geotechnical material sample to be sampled.

[0039] In this embodiment, the cylindrical rock-soil material sample to be sampled is a cylindrical coal sample retrieved from the site.

[0040] 102. According to the predicted size of the cube remodeling regular shape, process and manufacture a molding mold with a cubic inner cav...

Embodiment 2

[0058] In this embodiment, the difference from Embodiment 1 is that the cylindrical rock-soil material sample to be sampled in step 101 is a soil sample, and the diameter of the cylindrical soil sample is Φ100 mm and its height is 100 mm. First of all, the soil sample should be prepared according to the conventional method and the soil sample should be made by pressing the mold, and the dry density of the undisturbed soil used is 1.7g / cm 3 , the moisture content is 16.7%. In step 102, the formed mold is a square wooden box with an inner cavity of 130mm×130mm×150mm. When loading the mold in step 104, it is also necessary to mark the center position of the soil sample on the upper part of the asphalt mixture wrapped outside the soil sample. In step 105, cold water is used for demoulding. Before the demoulding, first reshape the molding mold together with the cube inside it into a regular shape, let it stand for cooling for 2 minutes, then put it into cold water for demoulding,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com