Piston for two-stroke crank round sliding block internal-combustion engine and internal-combustion engine thereof

A technology of crank round sliders and internal combustion engines, applied in the direction of internal combustion piston engines, pistons, combustion engines, etc., to achieve good scavenging effect, improve scavenging efficiency, and improve combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

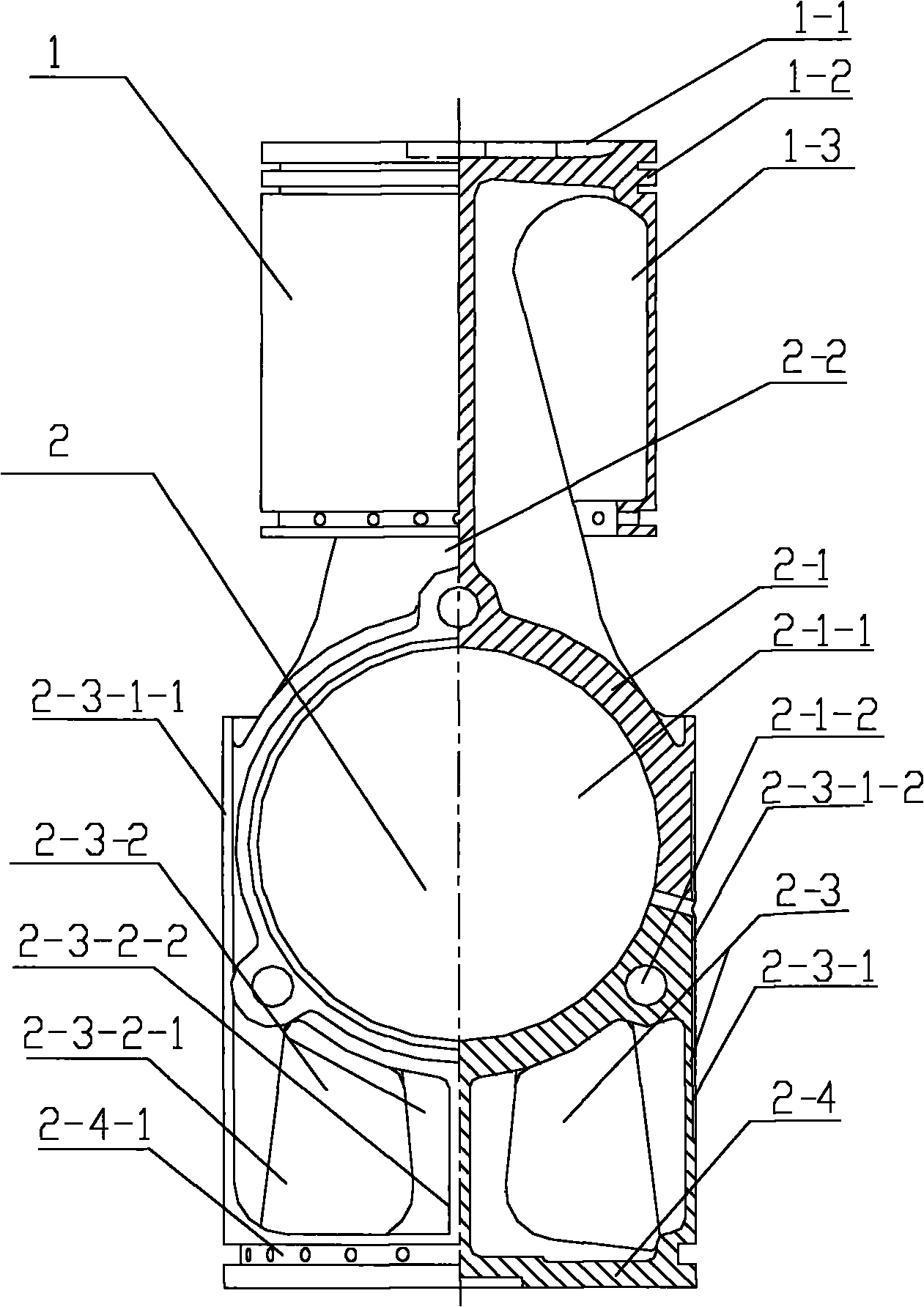

[0035] The piston seat 2 as a whole is a flat frame structure with a circular seat bottom at the bottom, which can be divided into a circular slider housing body 2-1, an upper connecting frame 2-2, a guide part 2-3, and a scavenging piston crown part 2- 4 in three parts. Please see also Figure 4 , which shows a half-sectional view of the piston seat 2.

[0036] The slider accommodating body 2-1 is located in the middle of the frame mechanism of the piston seat 2. The slider accommodating body 2-1 is ring-shaped, and its center is the slider accommodating hole 2-1 for accommodating the slider. 1-1, the diameter of the accommodating hole 2-1-1 of the circular slider is adapted to the sliding bearing or rolling bearing to be arranged and matched with the circular slider. According to needs, the opening of the circular slider accommodating hole 2-1-1 is provided with an axial positioning structure, such as a step, a notch, and the like. In actual use, the single-cylinder inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com