Generator local discharge on-line monitoring device and monitoring method thereof

A partial discharge and monitoring device technology, applied in the field of generator partial discharge on-line monitoring device, can solve problems such as single anti-interference means, low measurement bandwidth, and reduced sensitivity and reliability of measurement results, so as to achieve good anti-dry effect and improve reliability High safety and high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

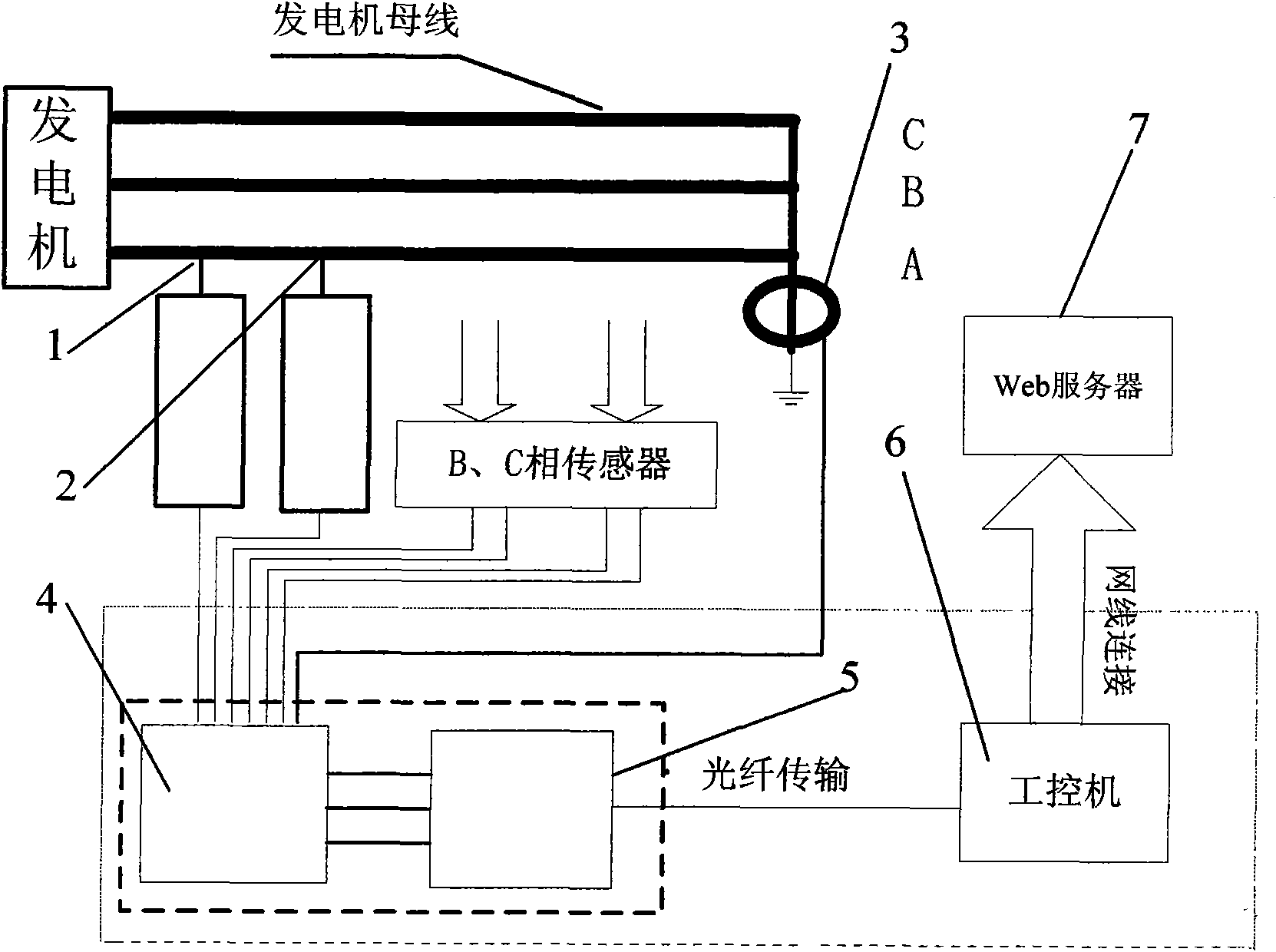

[0042] An online monitoring method for partial discharge of generators, including the following steps:

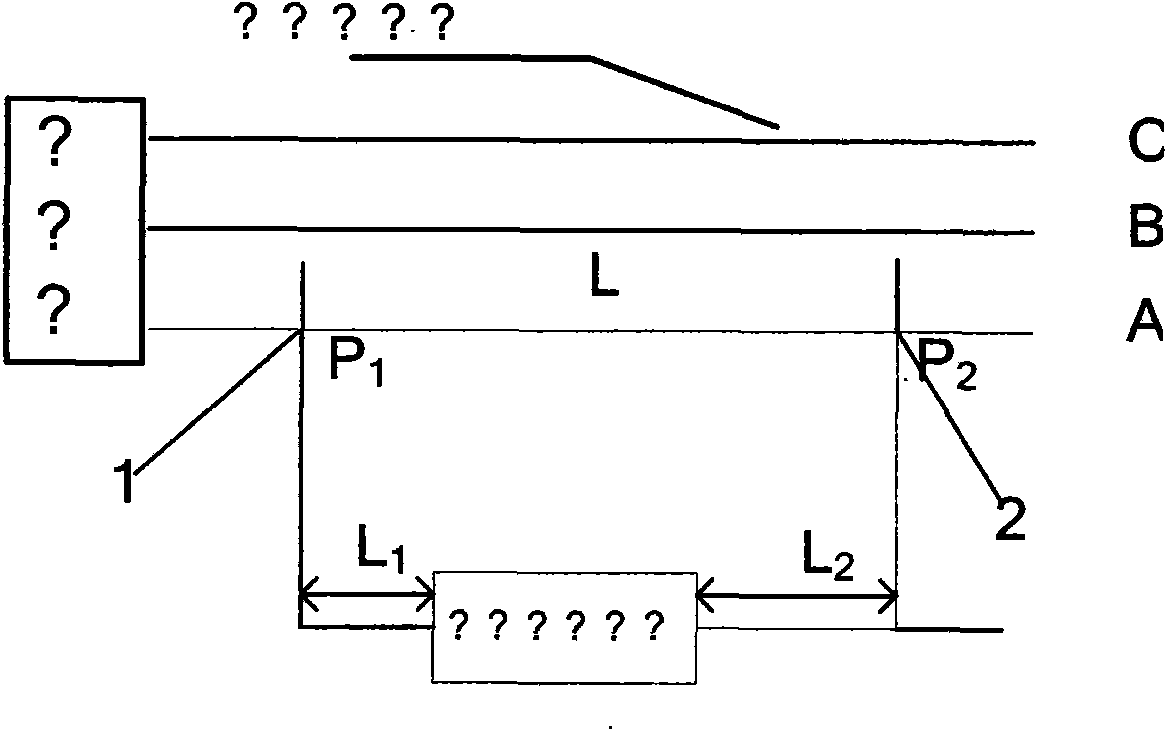

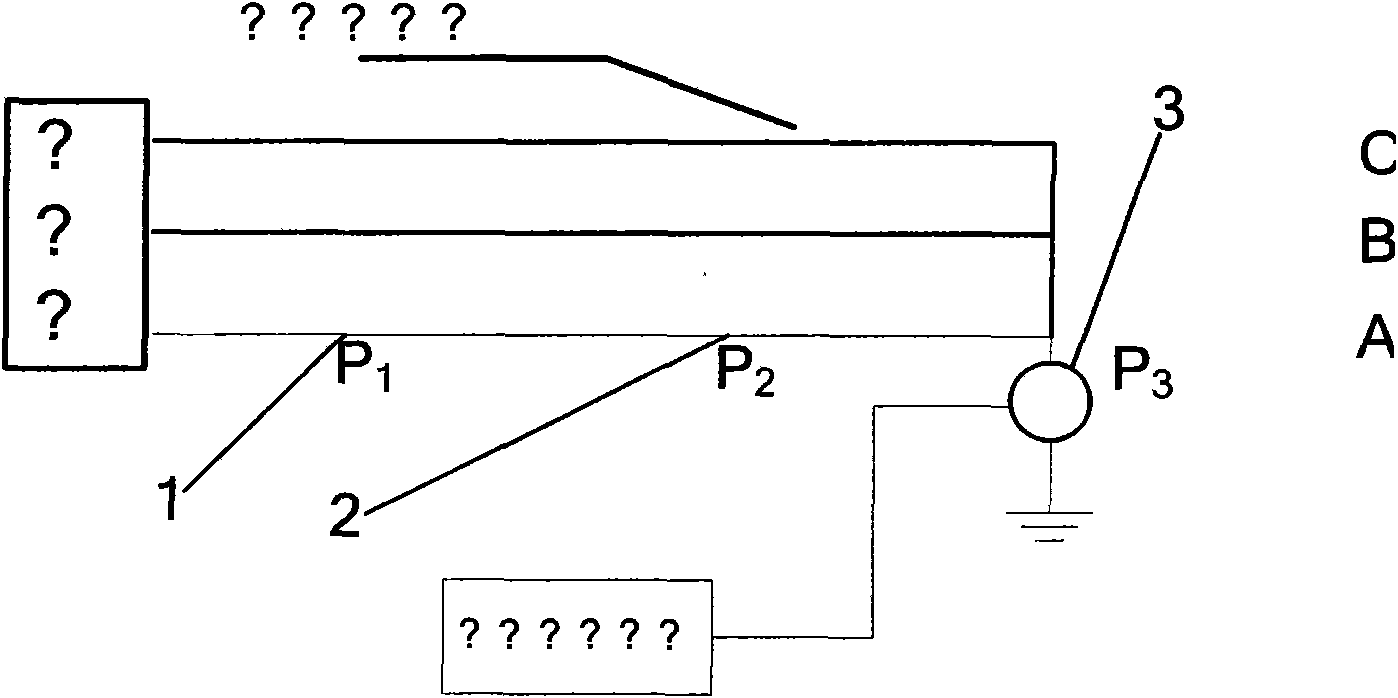

[0043] In the first step, a ceramic capacitance sensor 1 and a ceramic capacitance sensor 2 are installed on the generator bus. The ceramic capacitance sensor 1 is installed at the outlet end of the generator bus. The ceramic capacitance sensor 2 is installed in the same direction 15m away from the ceramic capacitance sensor 1. Place, while satisfying the formula

[0044] L 2 V a = L 1 V a + L V

[0045] Among them, the distance between the signal acquisition device and the ceramic capacitance sensor 1 is L 1 Is 35m, the distance between the signal acquisition device and the ceramic capacitance sensor 2 is L 2 Is 50m, the distance between ceramic capacitance sensor 1 and ceramic capacitance sensor 2 is 15m, V a Is the transmission speed of the signal in the cable, V is the transmission speed of the signal in the bus, and V is known a =0.8...

Embodiment 2

[0050] An online monitoring method for partial discharge of generators, including the following steps:

[0051] In the first step, a ceramic capacitance sensor 1 and a ceramic capacitance sensor 2 are installed on the generator bus. The ceramic capacitance sensor 1 is installed at the outlet end of the generator bus. The ceramic capacitance sensor 2 is installed in the same direction 8m away from the ceramic capacitance sensor 1. Place, while satisfying the formula

[0052] L 2 V a = L 1 V a + L V

[0053] Among them, the distance between the signal acquisition device and the ceramic capacitance sensor 1 is L 1 Is 25m, the distance between the signal acquisition device and the ceramic capacitance sensor 2 is L 2 Is 33m, the distance between ceramic capacitance sensor 1 and ceramic capacitance sensor 2 is 8m, V a Is the transmission speed of the signal in the cable, V is the transmission speed of the signal in the bus, and V is known a =0.8V,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com