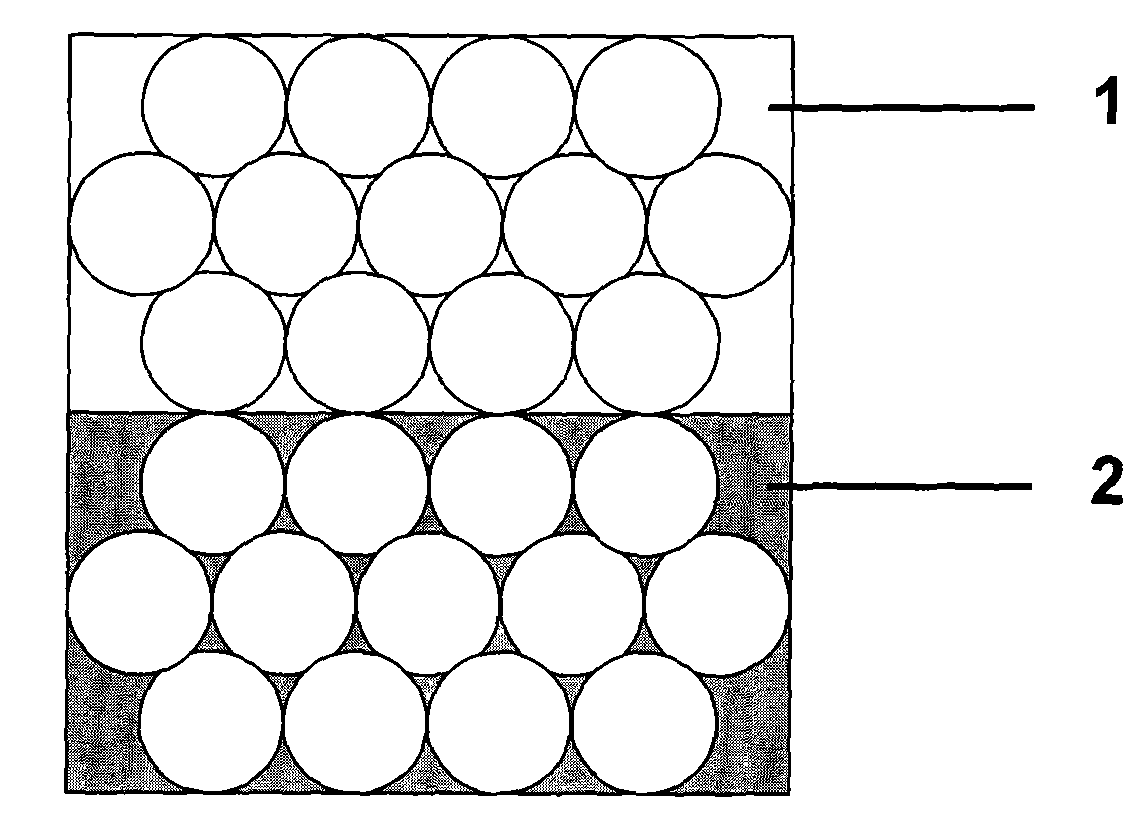

Preparation method of inverse opal hydrogel photonic crystal with double layer hybridized structure

A hybrid structure, inverse opal technology, used in optics, nonlinear optics, instruments, etc., can solve problems such as limited application and fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] (1) Disperse the uniform monodisperse silica microspheres in ethanol to form a solution with a mass fraction of 4%, then pour the solution into a clean container, and finally insert the clean substrate vertically into the above-mentioned In a container containing a monodisperse silica microsphere ethanol solution, place it in a closed environment at room temperature for one week to deposit the silica microspheres on the surface of the substrate to form opal colloidal crystals. The substrate is a glass sheet or Silicon wafer; the diameter of the silica microspheres is 180nm;

[0012] (2) Immerse the vertical liquid surface of the substrate processed in step (1) in the polyacrylic acid monomer solution for 3 minutes. The concentration of the polyacrylic acid monomer solution is 5M, and the polyacrylic acid monomer solution contains 10% crosslinked agent N, N'-methylenebisacrylamide and 3% photoinitiator 1-hydroxycyclohexylbenzophenone, so that polyacrylic acid monomers ca...

Embodiment 2

[0015] (1) Disperse the uniform monodisperse silica microspheres in ethanol to form a solution with a mass fraction of 1%, then pour the solution into a clean container, and finally insert the clean substrate vertically into the above-mentioned In a container containing a monodisperse silica microsphere ethanol solution, place it in a closed environment at room temperature for one week to deposit the silica microspheres on the surface of the substrate to form opal colloidal crystals. The substrate is a glass sheet or Silicon wafer; the diameter of the silica microspheres is 232nm;

[0016] (2) Immerse the vertical liquid surface of the substrate processed in step (1) in the polyacrylic acid monomer solution for 3 minutes, the concentration of the polyacrylic acid monomer solution is 4M, and the polyacrylic acid monomer solution contains 5% crosslinked agent N, N'-methylenebisacrylamide and 3% photoinitiator 1-hydroxycyclohexylbenzophenone, so that polyacrylic acid monomers can...

Embodiment 3

[0019] (1) Disperse the uniform monodisperse silica microspheres in ethanol to form a solution with a mass fraction of 0.5%, then pour the solution into a clean container, and finally insert the clean substrate vertically into the above-mentioned In a container containing a monodisperse silica microsphere ethanol solution, place it in a closed environment at room temperature for one week to deposit the silica microspheres on the surface of the substrate to form opal colloidal crystals. The substrate is a glass sheet or Silicon wafer; the diameter of the silica microspheres is 300nm;

[0020] (2) Immerse the vertical liquid surface of the substrate processed in step (1) in the polyacrylic acid monomer solution for 3 minutes. The concentration of the polyacrylic acid monomer solution is 1M, and the polyacrylic acid monomer solution contains 1% crosslinked agent N, N'-methylenebisacrylamide and 3% photoinitiator 1-hydroxycyclohexylbenzophenone, so that polyacrylic acid monomers c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com