Film component extraction apparatus

A technology for taking out devices and components, which is applied in the field of film component taking out devices, can solve problems such as taking out easily unstable sheets, and achieve the effects of reducing sliding, height positioning, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

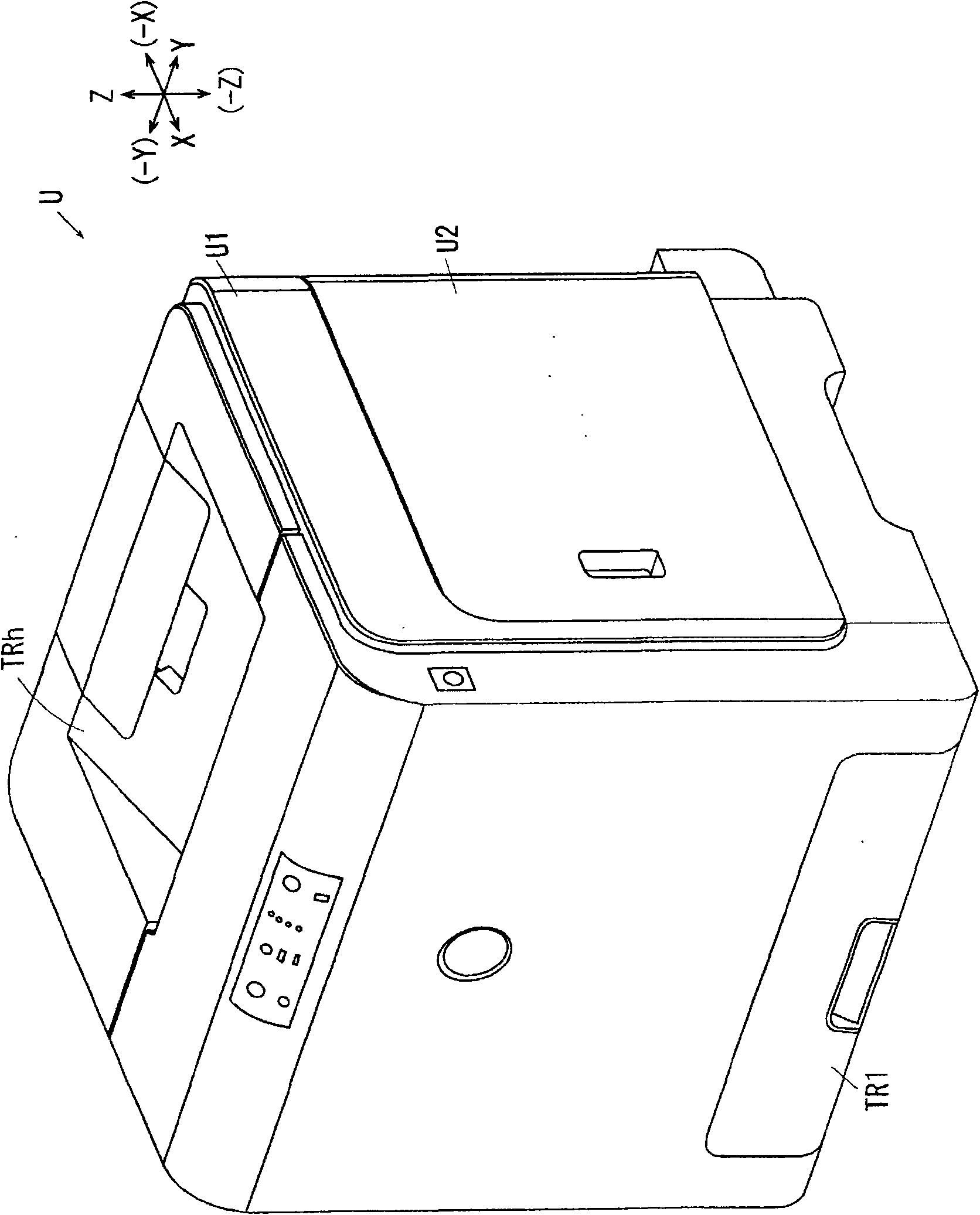

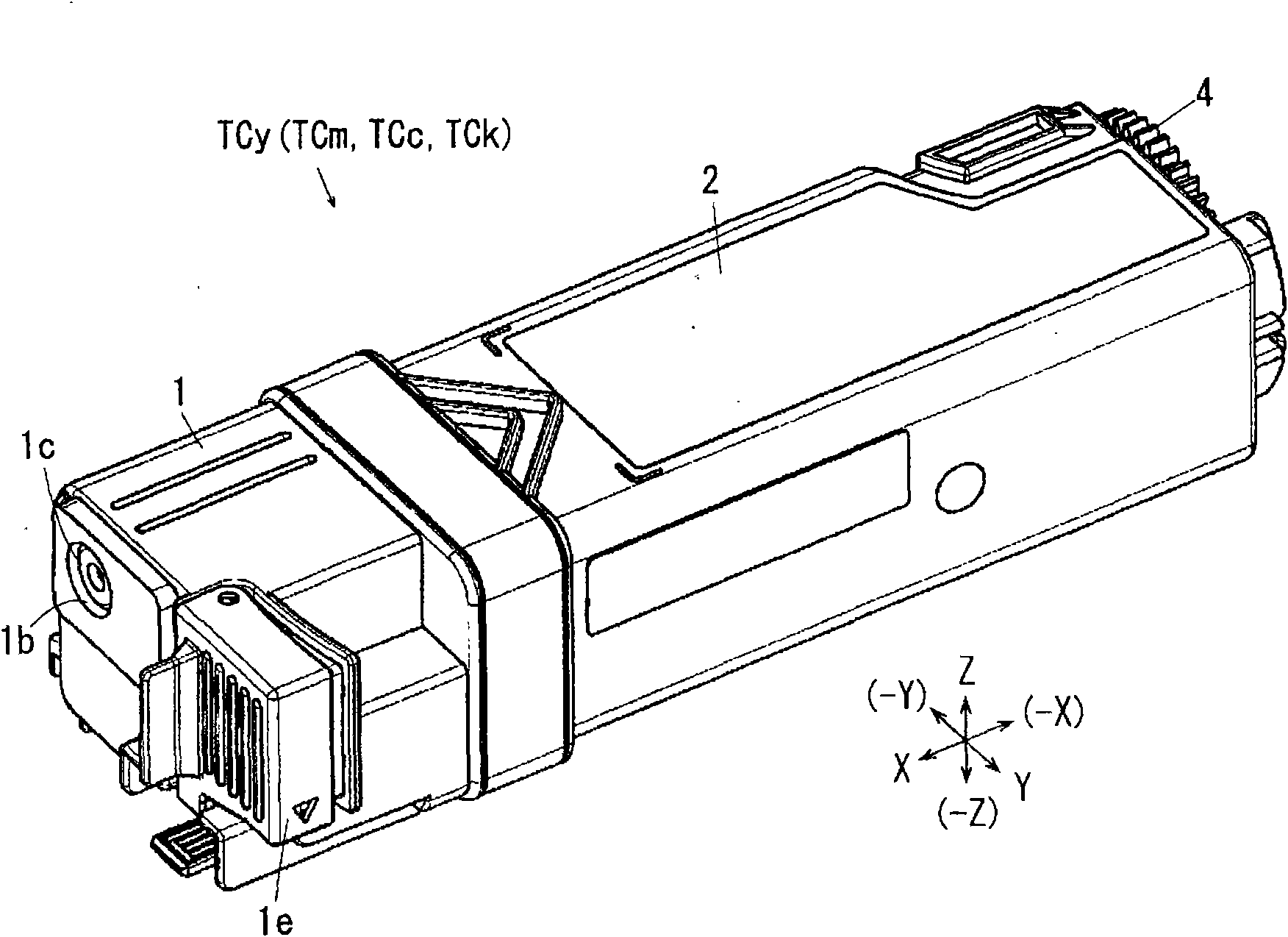

[0087] figure 1 It is a perspective view of a printer as an example of an image forming apparatus using a replacement container in which the film member separation device according to Example 1 of the present invention is used and assembled.

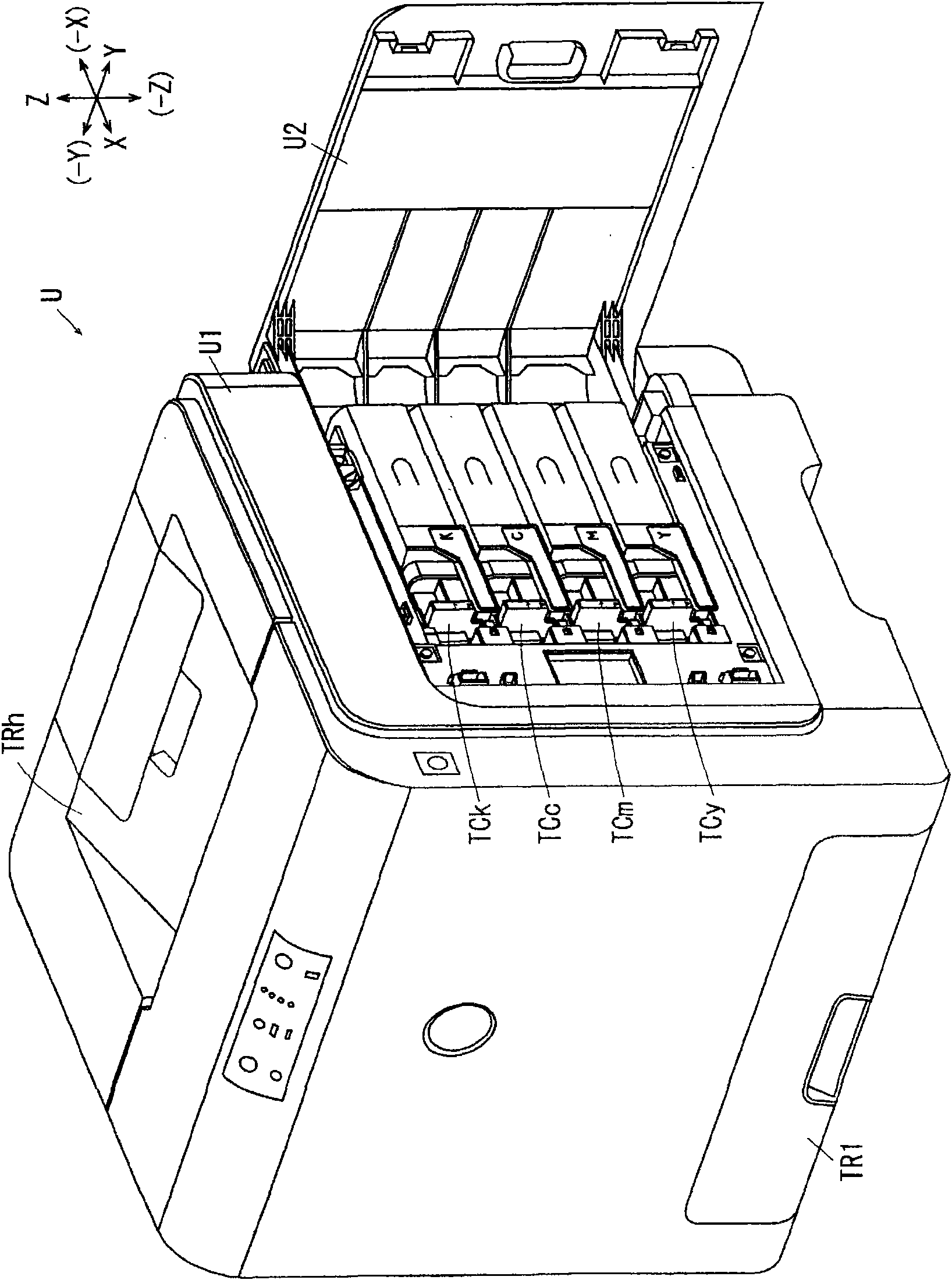

[0088] figure 2 for in figure 1 An explanatory diagram of the printer shown with the side cover open.

[0089] exist figure 1 , figure 2Among them, the full-color digital printer U of Embodiment 1 of the image forming apparatus of the present invention has an image forming apparatus main body U1. A paper feed tray TR1 as an example of a medium supply unit is supported on the lower portion of the image forming apparatus main body U1, and accommodates a medium on which an image is to be recorded on the front surface, and can be inserted and removed in the front-rear direction. On the upper surface of the image forming apparatus main body U1, there is formed a paper discharge tray TRh as an example of a medium discharge unit that ...

Embodiment 2

[0356] Figure 25 It is an explanatory diagram of the film taking-out device of Example 2, which is the same as that of Example 1. Figure 7 corresponding figure.

[0357] Figure 26 It is an explanatory drawing of the film storage box of the film apparatus of Example 2, and is a figure corresponding to FIG. 15 of Example 1. FIG.

[0358] Next, Embodiment 2 of the present invention will be described. In the description of Embodiment 2, constituent elements corresponding to constituent elements of Embodiment 1 are given the same reference numerals, and detailed description thereof will be omitted.

[0359] This second embodiment differs from the above-mentioned first embodiment in the following points, but is configured in the same manner as the first embodiment in other respects.

[0360] exist Figure 25 In the film take-out device FT of Example 2, compared with Example 1, the hoses 72' of the left blowing part 61e and the right blowing part 61f are connected to the gas s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com