Method for connecting composite high-strength soft belt with longitudinal interface thereof

A connection method and soft belt technology, which is applied in the direction of hoses, pipes/pipe joints/fittings, pipes, etc., can solve the problems that the water pipe cannot be folded and rolled, the connection method is not suitable, and the water pipe is under heavy pressure. The effect of irrigation cost, light weight and long repeated service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

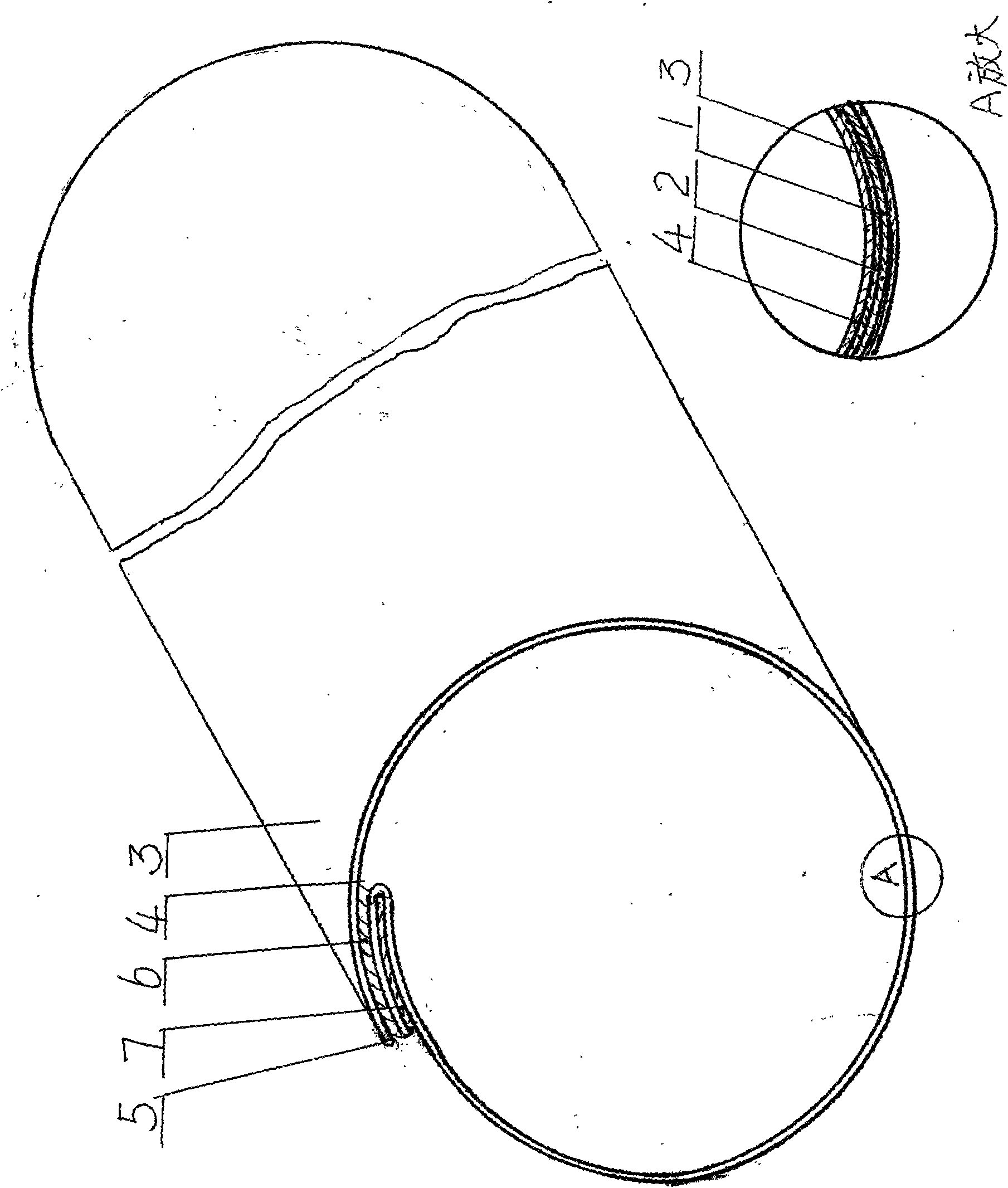

[0014] like figure 1 Shown: The inner and outer layers of a single piece of PE woven fabric 1 are coated with a layer of colored A coating 2 and B coating 3 respectively, and then a waterproof layer is compounded on the outer layer of A coating 2 on the inner layer of PE woven fabric 1 Membrane 4, PE woven fabric 1 After connecting the two cut sides in the longitudinal direction, a soft belt is formed. The connection method of the two cut sides is to align the A ends 5 of the two cut sides, and coat a layer of A glue in the middle Layer 6, and then, fold the two cut edges that have been bonded together on the PE woven cloth 1 to the outside of the soft belt, and apply another layer on the contact between the two cut edges and the PE woven cloth 1 B viscose layer 7, water does not directly contact cutting edge so can not seep from this place.

[0015] Its advantages are: light weight, low labor intensity during transportation and handling, fast and convenient installation, str...

Embodiment 2

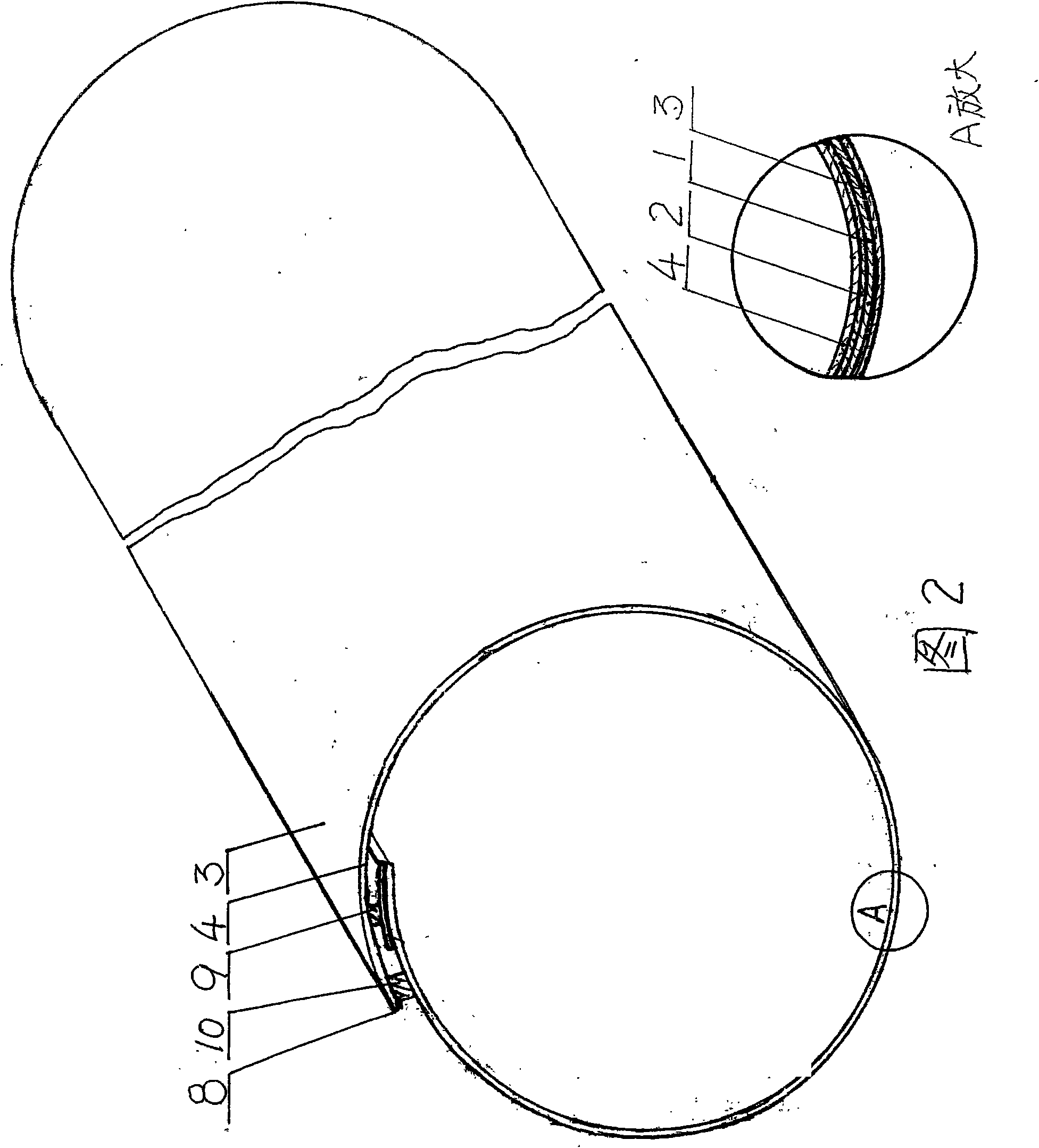

[0017] like figure 2 Shown: The inner and outer layers of a single piece of PE woven fabric 1 are coated with a layer of colored A coating 2 and B coating 3 respectively, and then a waterproof layer is compounded on the outer layer of A coating 2 on the inner layer of PE woven fabric 1 After the film 4 and PE woven fabric 1 are connected longitudinally with two cut sides, a soft belt is formed. The connection method of the two cut sides is to stagger the B ends 8 of the two cut sides back and forth. A layer of C viscose layer 9 is applied to the edge contact, and then the two staggered cutting edges are bonded together. One deck of D viscose adhesive layer 10 is coated on the contact position of a piece of cutting edge and PE woven cloth 1 in the front where the cutting edge is staggered, so it can not leak from this place because water does not directly contact the cutting edge.

[0018] Its advantage is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com