TFT-LCD array substrate structure and preparation method thereof

An array substrate structure and substrate technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, instruments, etc., can solve the problem of reducing the aperture ratio of TFT-LCD, reducing the effective display area of the array substrate, and the opening of TFT-LCD. rate reduction and other issues, to achieve the effect of increasing the aperture ratio, improving product performance, and reducing line resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

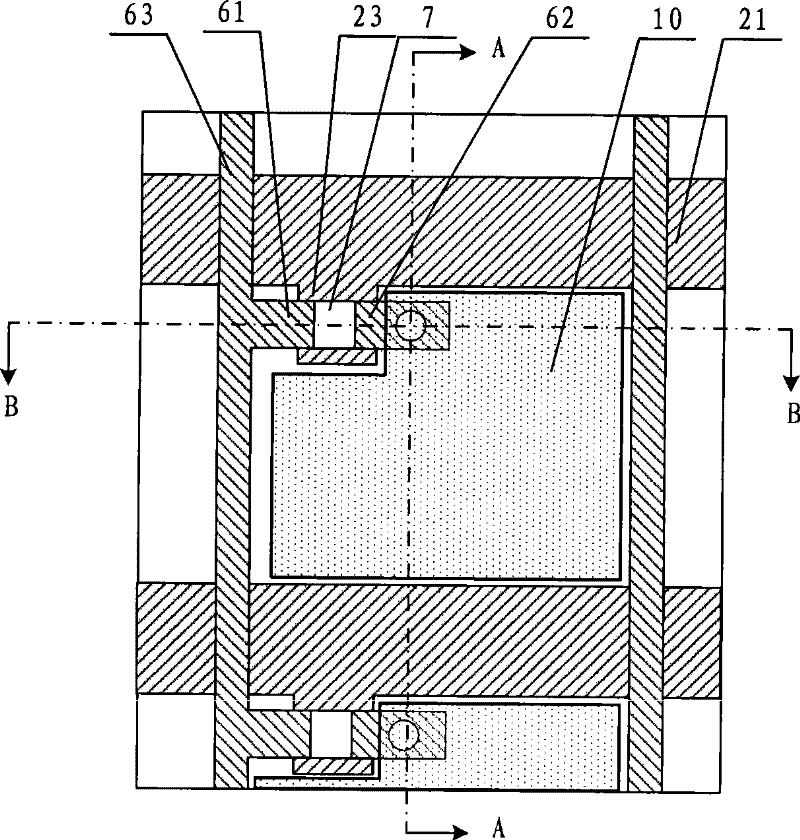

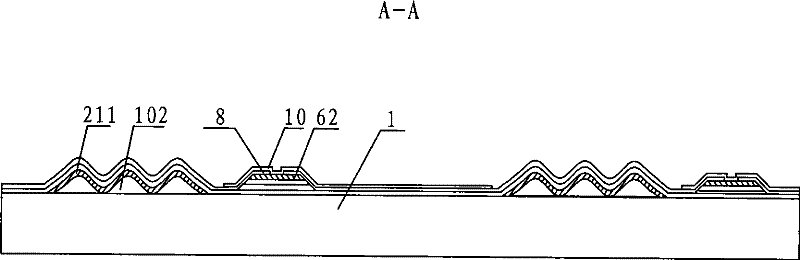

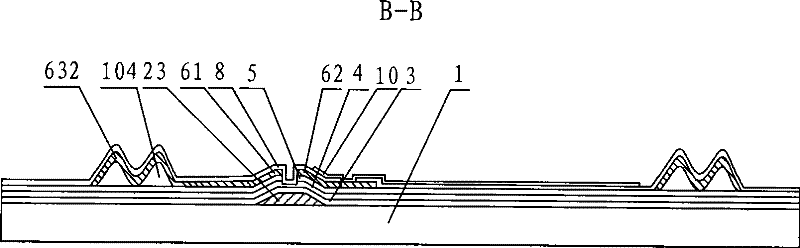

[0056] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0057] In each of the following detailed embodiments, the normal grid line or normal data line is the grid line or data line formed by the existing TFT-LCD array substrate structure preparation method, and the shape of the cross section of the grid line or data line is a rectangle; Shaped grid lines or wavy data lines are new grid lines or new data lines that can be formed by the improved TFT-LCD array substrate structure preparation method of the present invention, and the new grid lines or new data lines are formed on the wavy base of the substrate , the cross-sectional shape of the wavy base along the width direction is wavy; the cross-sectional shape of the new grid line or new data line formed on the wavy base along the width direction is an undulating curve similar to waves, that is, wavy.

[0058] Figure 1a It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com