Electronic product outer shell and manufacturing method thereof

A manufacturing method and technology for electronic products, applied in electrical equipment casings/cabinets/drawers, layered products, chemical instruments and methods, etc., can solve problems such as poor mechanical strength, and achieve high mechanical strength, beautiful appearance, and metallic texture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

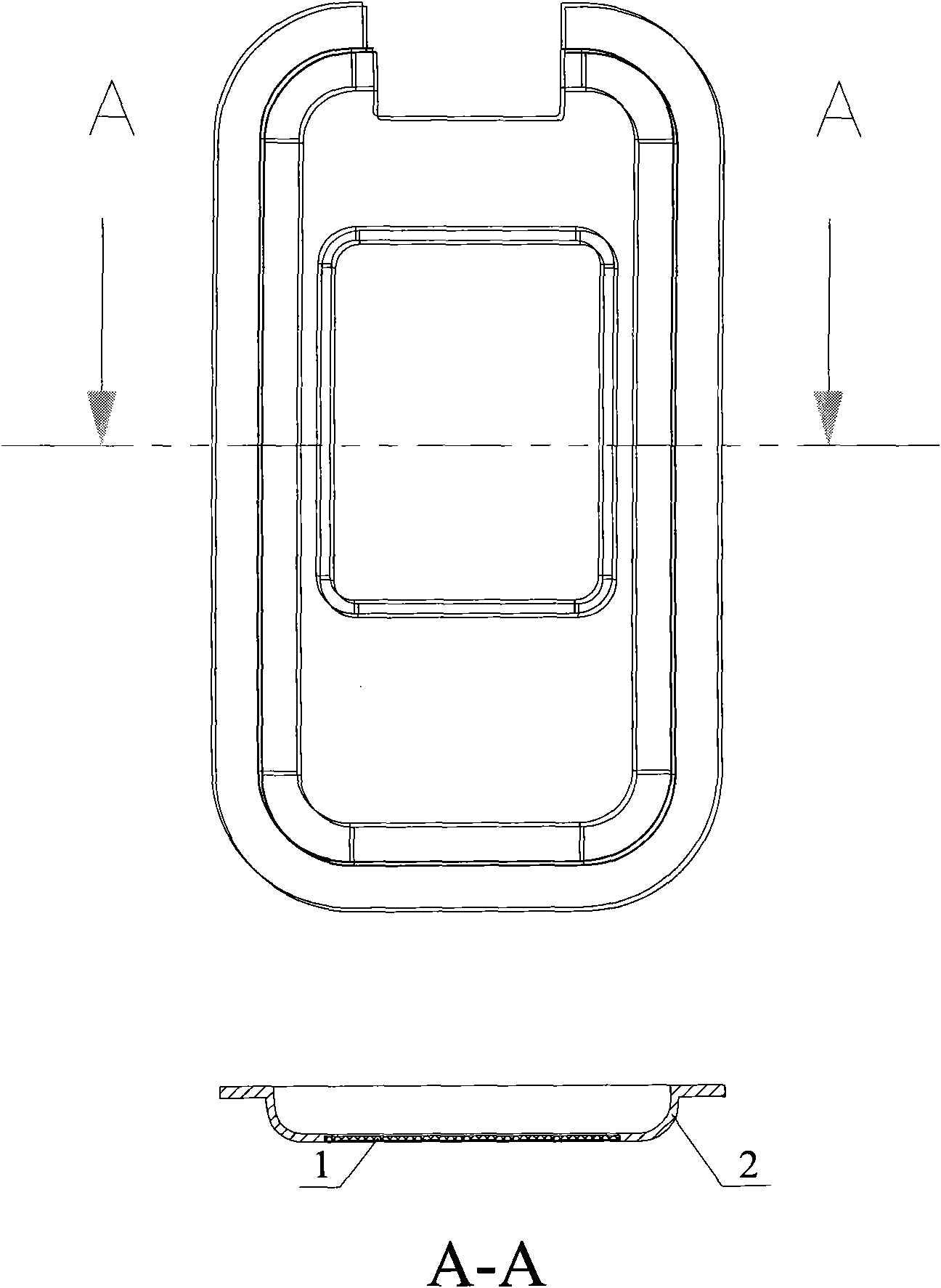

[0027] According to the manufacturing method of the electronic product casing provided by the present invention, in a preferred case, the preparation method includes the following steps,

[0028] Provide more than two layers of carbon fiber cloth with staggered grain directions pre-impregnated with thermosetting resin with a central viewing window;

[0029] Lay the multi-layer carbon fiber cloth in the preheating press mold, preheat and press out the edge around the reserved viewing window, the width of the edge is 0.5-2 mm, and the temperature of the preheating press is 100-180 ℃, the preheating pressure is 1-10MPa;

[0030] Place the transparent window on the edge of the reserved window of multi-layer carbon fiber cloth;

[0031] Cover the edge of the transparent window from the other side of the transparent window with a layer of carbon fiber cloth pre-impregnated with thermosetting resin, which also has a window, to obtain a stacked carbon fiber shell semi-finished produc...

Embodiment 1

[0036] The carbon fiber cloth is made of Toray T300 carbon fiber cloth (thickness is 0.125 mm), the epoxy resin is bisphenol F epoxy resin, and the transparent window is made of flat glass (ultra-thin float glass) of 42.57×32.22×0.57 mm.

[0037] 1. Preparation of carbon fiber shell

[0038] In a prepreg machine (Khosla, CD-8048), pre-impregnate two sheets of carbon fiber cloth with epoxy resin for 1 minute at room temperature, and pre-impregnate carbon fiber cloth with a pre-impregnated amount of 45% by weight of carbon fiber cloth. Cut it into 100×55 mm, cut out a reserved viewing window of 39.57×29.22 mm in the middle, and then lay it flat in the hot pressing mold with a staggered 45° in the direction of the grain, and preheat and extrude the edge with a width of 1.6 mm. 100°C, the preheating pressure is 3MPa;

[0039] The transparent window is placed on the edge of the reserved window which has been preheated and pressed, and a layer of carbon fiber prepreg with a prepreg...

Embodiment 2

[0047] The carbon fiber cloth is made of Toray T300 carbon fiber cloth (thickness is 0.125 mm), the epoxy resin is bisphenol A type epoxy resin, and the transparent window is made of flat glass (ultra-thin float glass) of 42.57×32.22×1 mm.

[0048] 1. Preparation of carbon fiber shell

[0049] In a prepreg machine (Khosla, CD-8048), pre-impregnate four sheets of carbon fiber cloth with epoxy resin for 1 minute at room temperature, and pre-impregnate carbon fiber cloth with a pre-impregnated amount of 55% by weight of carbon fiber cloth. Cut it into 100×55mm, and cut out a reserved viewing window of 39.57×29.22mm in the middle, and then spread it in the heat-pressing mold at a staggered 30° in the direction of the grain, and preheat the edge with a width of 0.8mm. The temperature is 180℃, and the preheating pressure is 1MPa;

[0050] The transparent window is placed on the edge of the reserved window which has been preheated and pressed, and a layer of carbon fiber prepreg wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com