Transfer device and linear-type apparatus for the manufacture of containers

A technology for conveying devices and containers, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve the problems of fragile containers, damaged containers, and unsightly appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

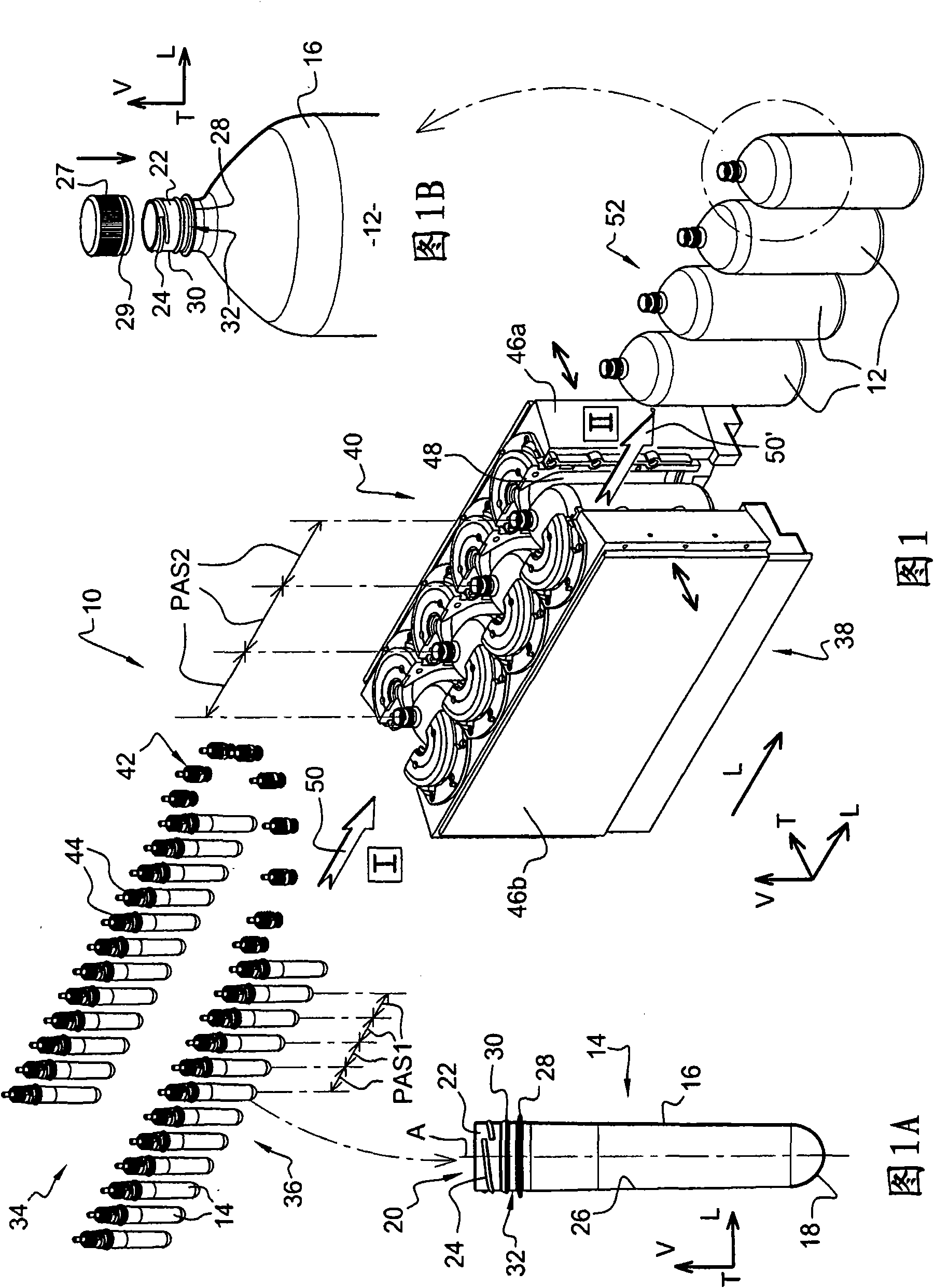

[0082] figure 1 A linear device 10 for producing containers 12 from preforms 14 is schematically shown.

[0083] In a known manner, the preform 14 is made of thermoplastic material, especially PET (polyethylene terephthalate), intended to be heated and then molded by blowing or with stretch-blowing to finally obtain a container 12, such as a vial or bottle.

[0084] The preform 14 is generally produced according to an injection molding process, which may be integrated with the apparatus or carried out at another location than the apparatus 10 .

[0085] Such as Figure 1A As shown, the preform 14 is generally in the shape of a tube, here extending vertically along a vertical main axis A. As shown in FIG.

[0086] The preform 14 has a body 16 , here generally cylindrical, closed at its lower end by a base 18 and, opposite, open at its upper end by an opening 20 delimited by the lip of a neck 22 .

[0087] From the bottom 18 to the neck 22, the cylindrical inner wall 26 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com