Corn directional seeding method, directional seed block manufacturing equipment and device for seeding seed blocks

A technology for manufacturing equipment and orientation devices, which is applied in the directions of seed treatment, sowing, climate change adaptation, etc., to achieve the effects of low cost, favorable positioning, and avoidance of seed block movement and angle changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

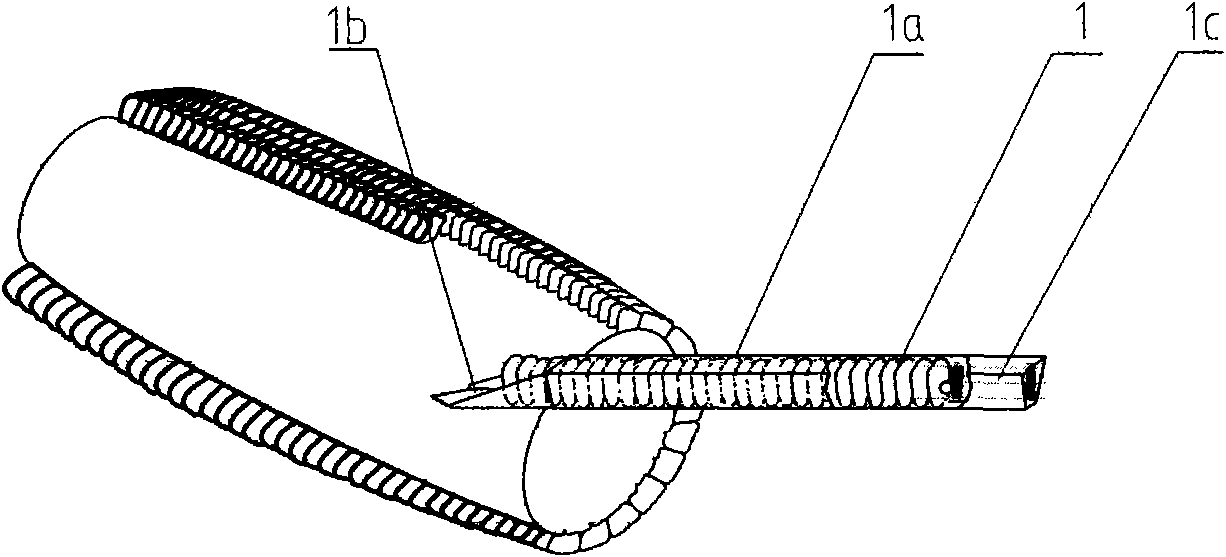

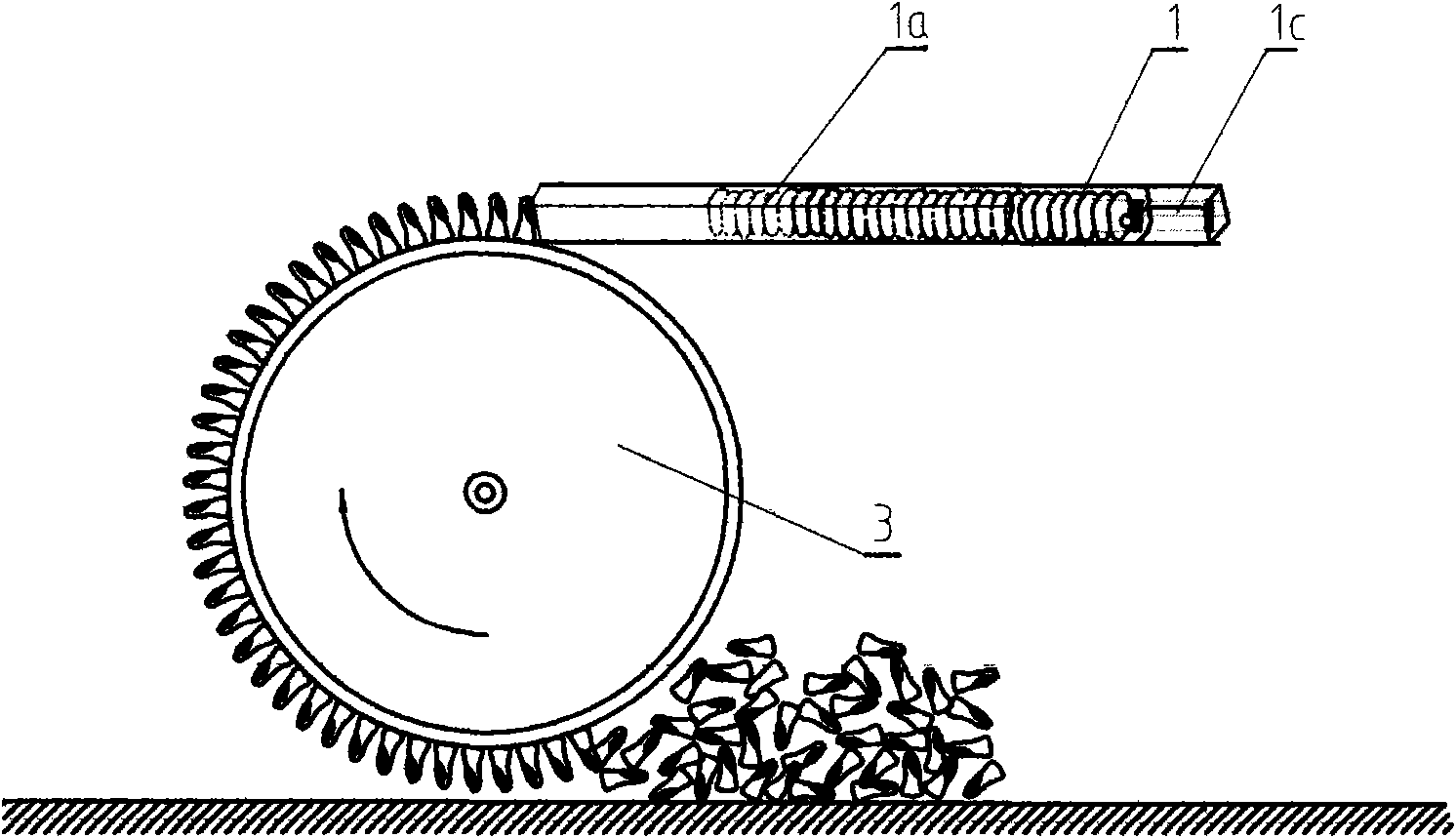

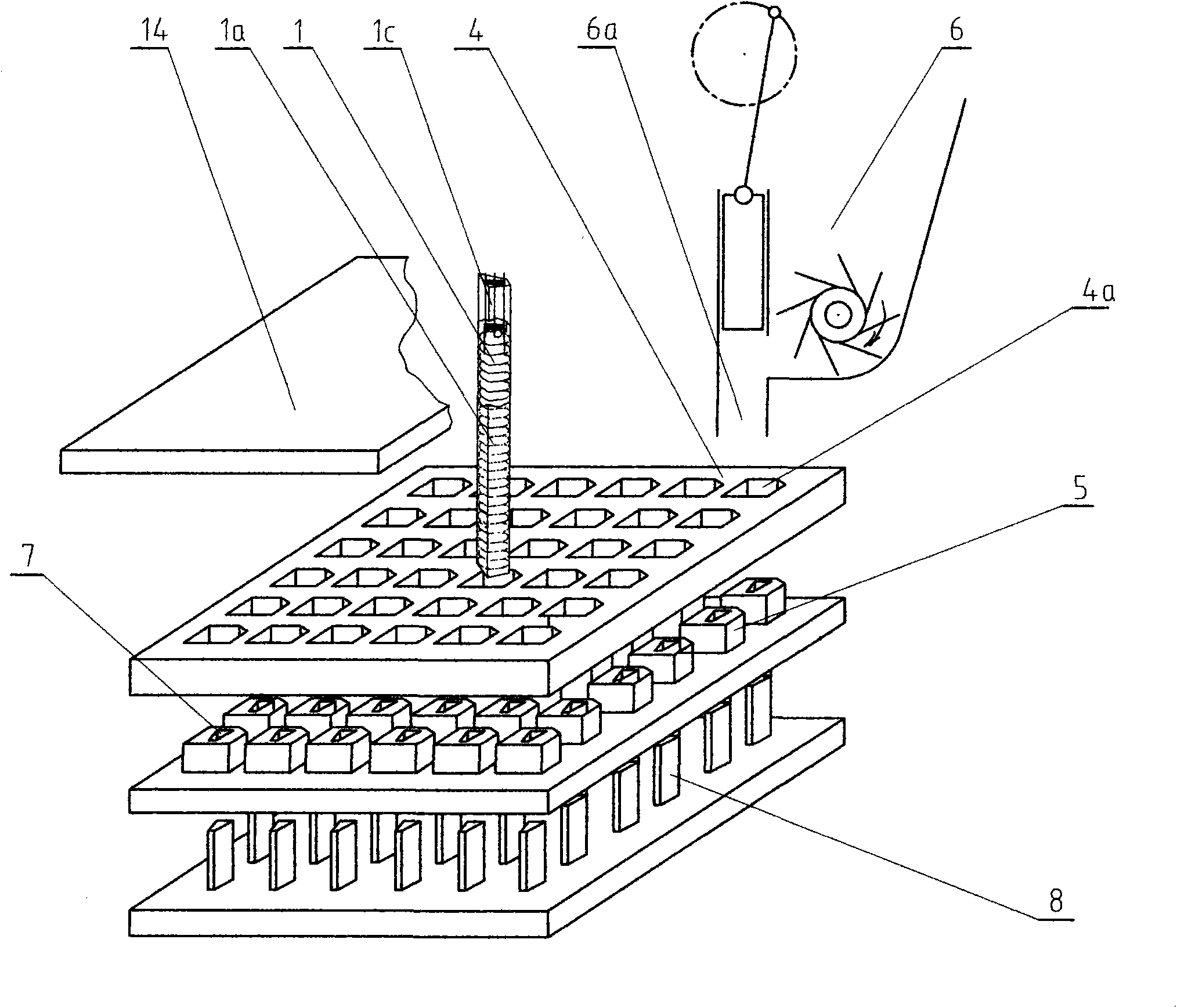

[0079] The corn directional sowing method described in the present invention comprises ear sorting method seed selection, corn seed strip 1 production, sowing carrier preparation and carrier directional sowing. When selecting seeds by the ear selection method, select whole ears that are free from diseases and insect pests, mature, and have regular shapes, and reject unqualified seeds. In order to identify the directionality of the seeds in the subsequent process, the identification color can be painted on one side of each row of seeds. The seed strip 1 is prepared according to the biological characteristics of corn seeds, that is, the seed strip 1 that keeps the germ surface of the seed on the seed ear and the direction of the germ is consistent and is packed into the seed strip box 1a. Maintaining the orderly arrangement of this biological feature will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com