Method for removing fine particles in dust-contained gas

A fine particle and gas removal technology, which is applied in chemical instruments and methods, solid separation, electrostatic effect separation, etc., can solve the problems of equipment cost and particle utilization weakness, and achieve the effect of compact and reasonable system structure and enhanced removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

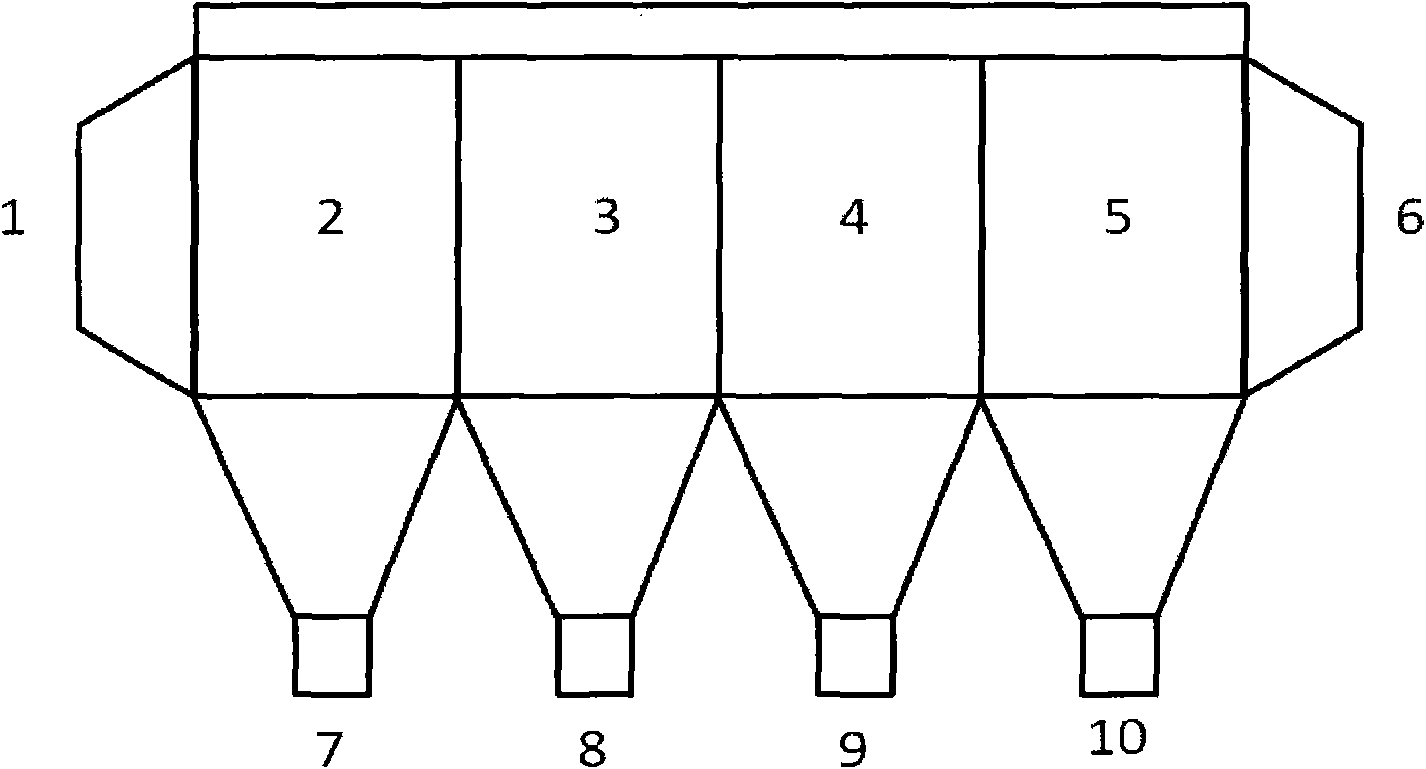

[0026] Example: the distance between the polar plate and the polar line is 75mm, the voltage is a DC power supply of 16KV, the velocity of the dusty gas is 0.6m / s, and the dust content is 1.55g / m 3 , using a water film to form a thermal swimming field, the average temperature of the plate is 50°C lower than the average temperature of the airflow, and the removal efficiency for fine particles with a particle size of less than 0.5 μm is higher than 40% of the removal efficiency when only the electrostatic dust removal field is applied.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com