Composite type heat preservation wall body mold block and composite type heat preservation wall body constructed by same

A thermal insulation wall, composite technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of falling off and increase the cost of wall construction, and achieve the effect of solving cold and heating bridges and good heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

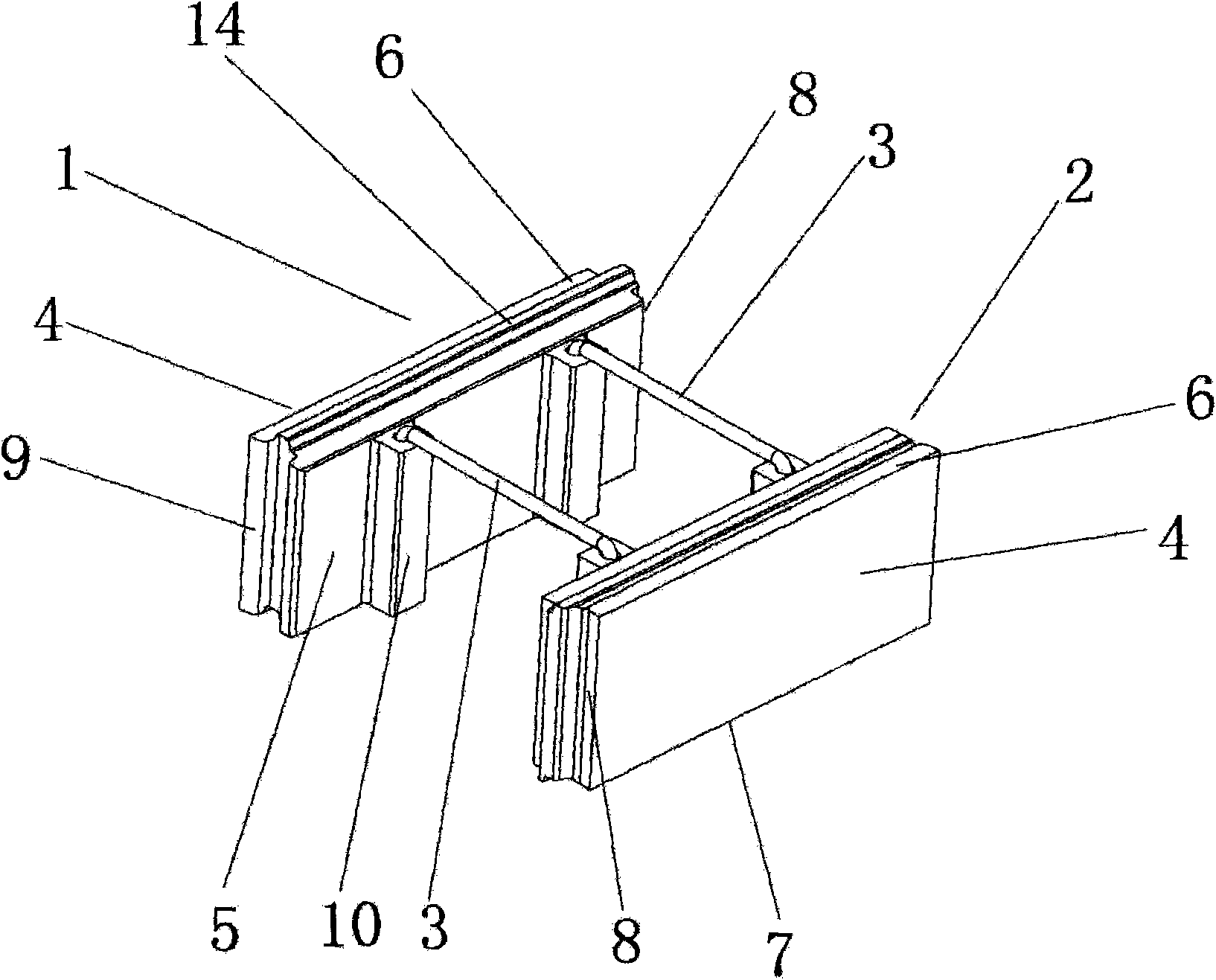

[0038] made from concrete figure 1 Formwork 1 and 2 of the cuboid composite thermal insulation wall module shown.

[0039] made of steel Figure 5 For the connecting piece 3 shown, the two ends of the connecting piece 3 are provided with hooks 13 .

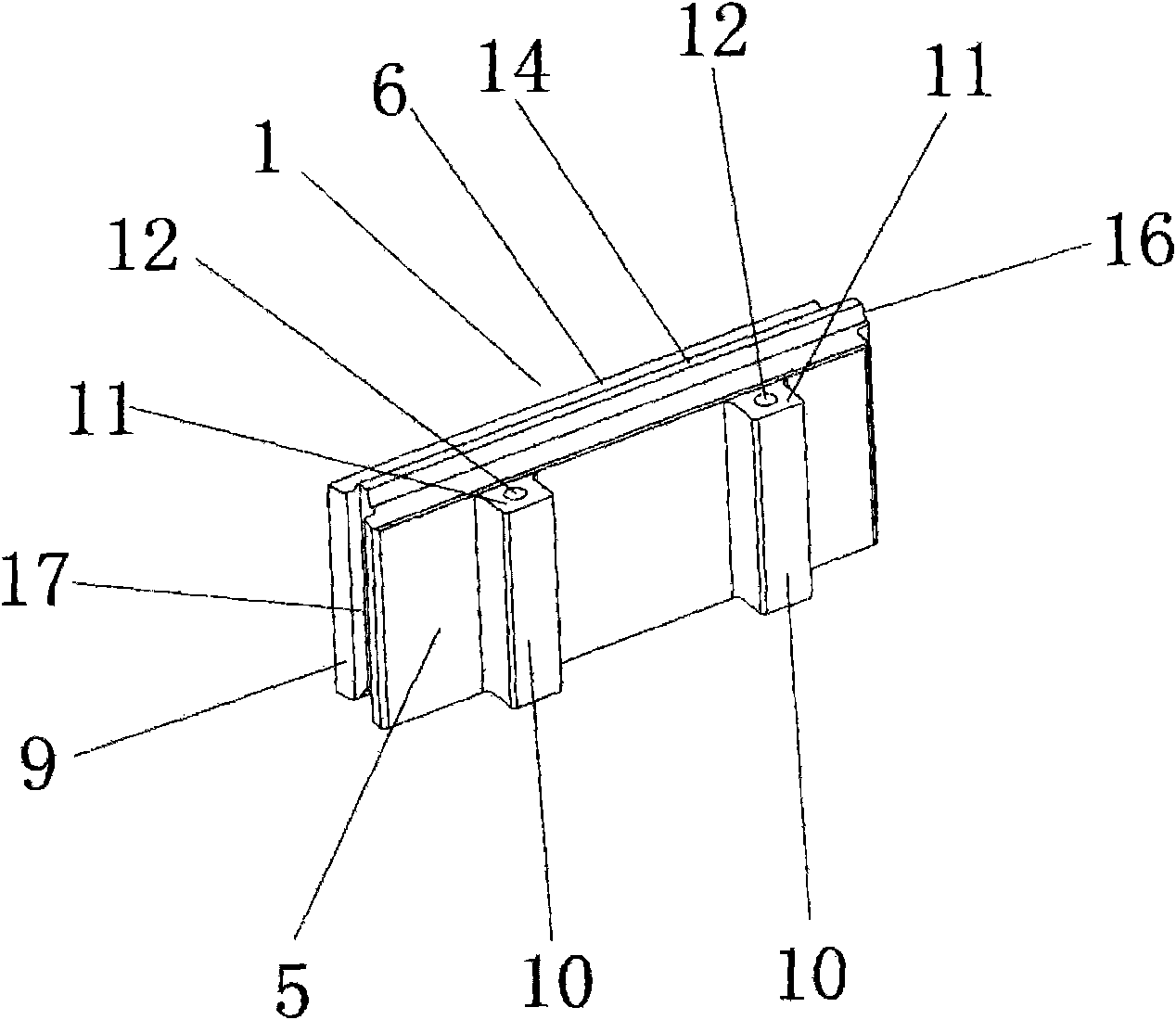

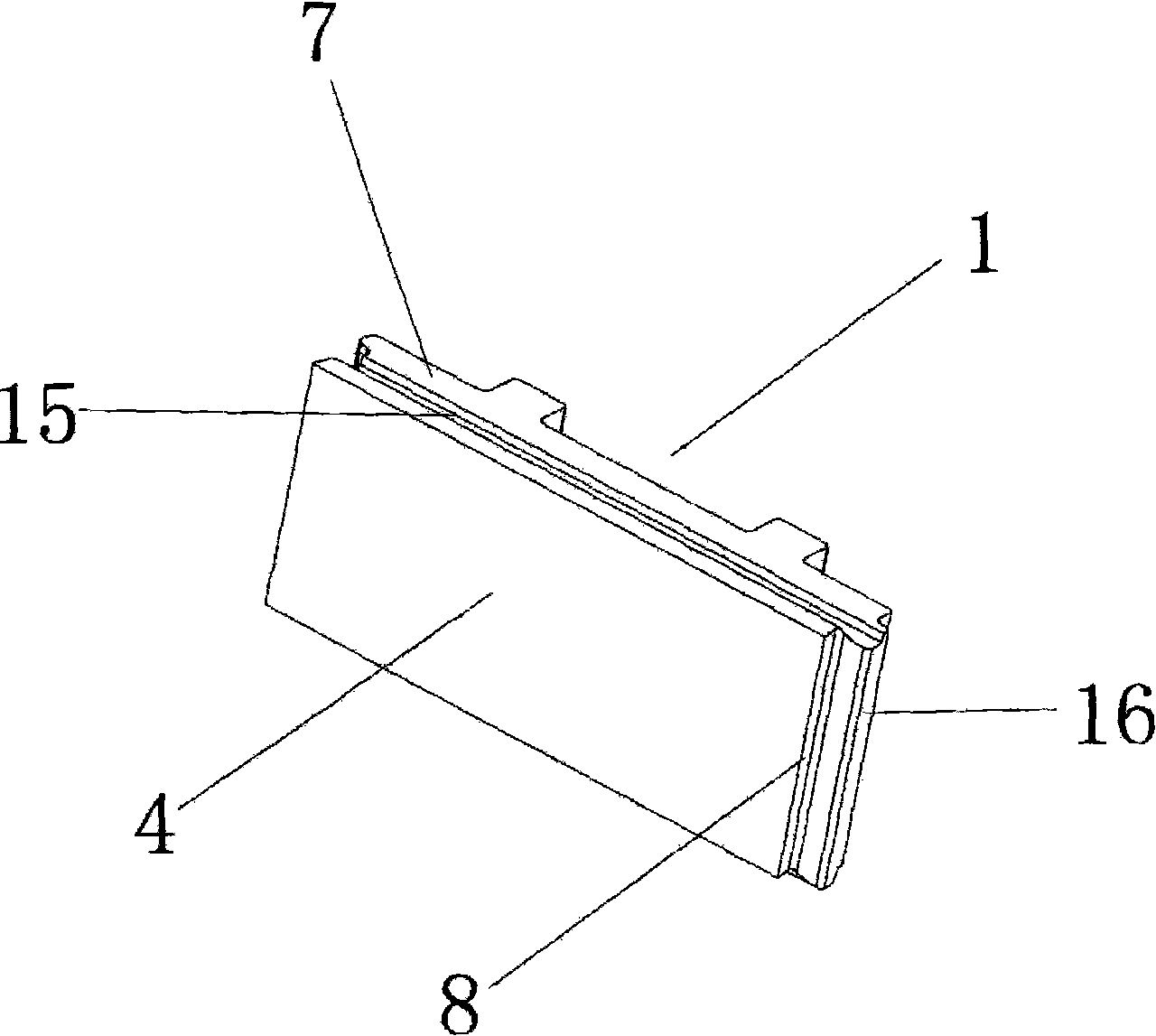

[0040] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown, the templates 1 and 2 of the composite thermal insulation wall module have an outer facade 4, an inner facade 5, an upper installation surface 6, a lower installation surface 7, and end surfaces 8 and 9, and the outer facades 4 of the templates 1 and 2 and the inner facade 5 are planes parallel to each other, the inner facade 5 is provided with a rib 10, and the upper end surface 11 of the rib 10 is provided with a longitudinal connection hole 12, and the hooks 13 at both ends of the connector 3 are respectively inserted into the rib The longitudinal connecting hole 12 on 10 makes the connecting piece 3 connect the templates 1 and 2 together, that is, for...

Embodiment 2

[0043] made from concrete Figure 4 Formwork 1 and 2 of the cuboid composite thermal insulation wall module shown.

[0044] made of steel Figure 5 For the connecting piece 3 shown, the two ends of the connecting piece 3 are provided with hooks 13 .

[0045] Such as Figure 4 and Figure 5 As shown, the templates 1 and 2 of the composite thermal insulation wall module have an outer facade 4, an inner facade 5, an upper installation surface 6, a lower installation surface 7, and end surfaces 8 and 9, and the outer facades 4 of the templates 1 and 2 and the inner facade 5 are planes parallel to each other, the inner facade 5 is provided with a rib 10, and the middle position of the rib 10 is provided with a transverse connection hole 21, and the hooks 13 at both ends of the connector 3 are inserted into the templates 1 and 2 respectively. The transverse connecting hole 21 on the raised rib 10 makes the connecting piece 3 connect the templates 1 and 2 together, that is, formi...

Embodiment 3

[0047] Such as Figure 6 The shown rectangular parallelepiped composite thermal insulation wall module includes templates 1 and 2 and a connector 3 connecting the templates 1 and 2 . Templates 1 and 2 have an outer facade 4, an inner facade 5, an upper placement surface 6, a lower placement surface 7, and end surfaces 8 and 9, and the outer facade 4 and the inner facade 5 of the templates 1 and 2 are mutually parallel planes , The inner facade 5 is provided with ribs 10 .

[0048] Such as Figure 7 As shown, connecting pieces 18 are provided at both ends of the connecting piece 3 .

[0049] During the process of forming the composite thermal insulation wall module with concrete, the connecting pieces 18 at both ends of the connecting piece 3 are embedded in preset positions. After the composite thermal insulation wall module is formed, the templates 1 and 2 and the connector 3 form an integral body, and the connector 3 connects the templates 1 and 2 together through the rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com