Belt tensioning device of vehicle engine

A technology of automobile engine and tensioning device, applied in the direction of transmission, machine/engine, belt/chain/gear, etc., can solve the problems of belt and rocker arm not returning in time, insufficient belt tension, small spring torque and damping, etc. Achieve the effect of eliminating the jitter of the wheel train belt, pressing down quickly and timely, and improving and recovering the tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

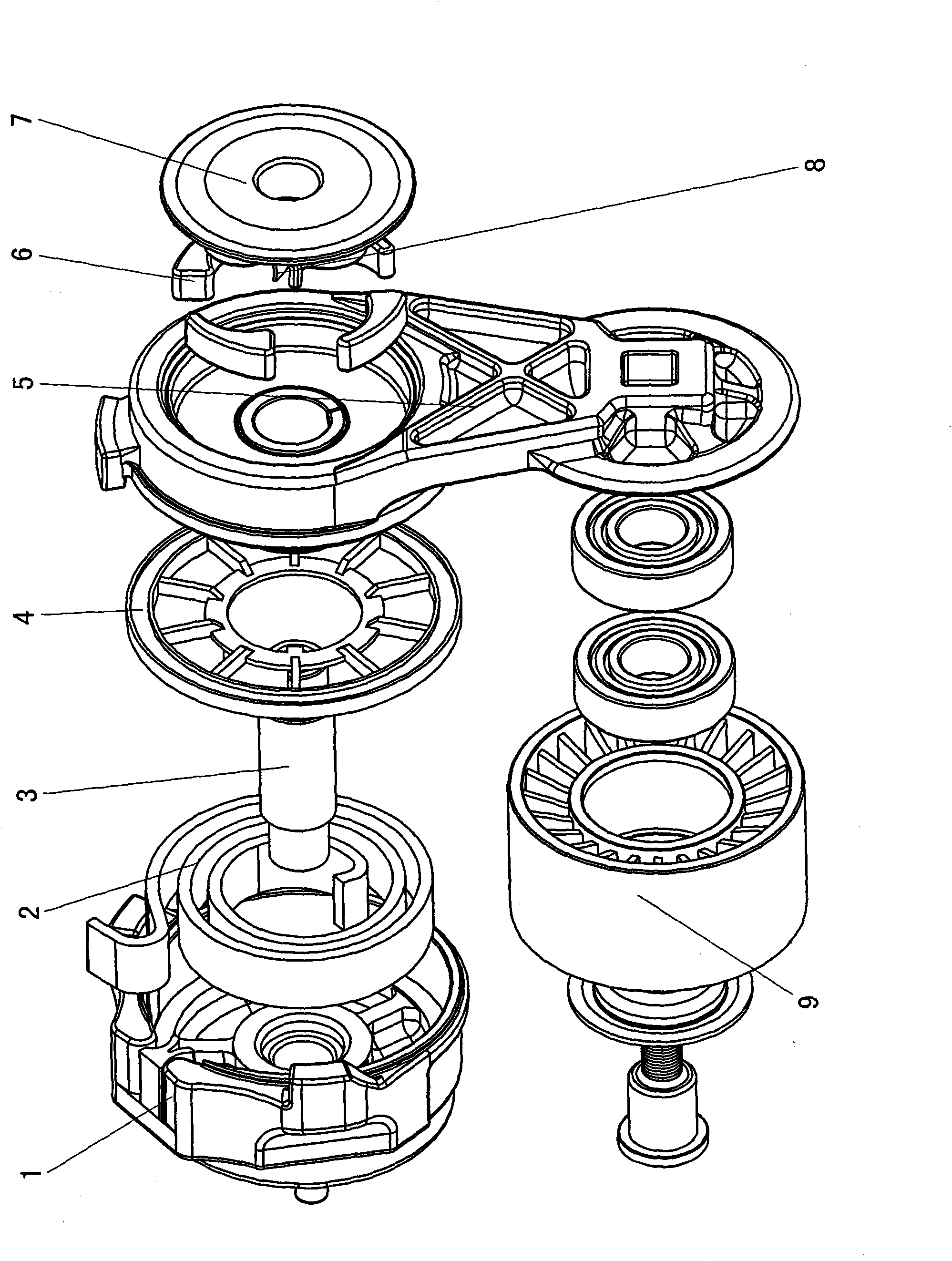

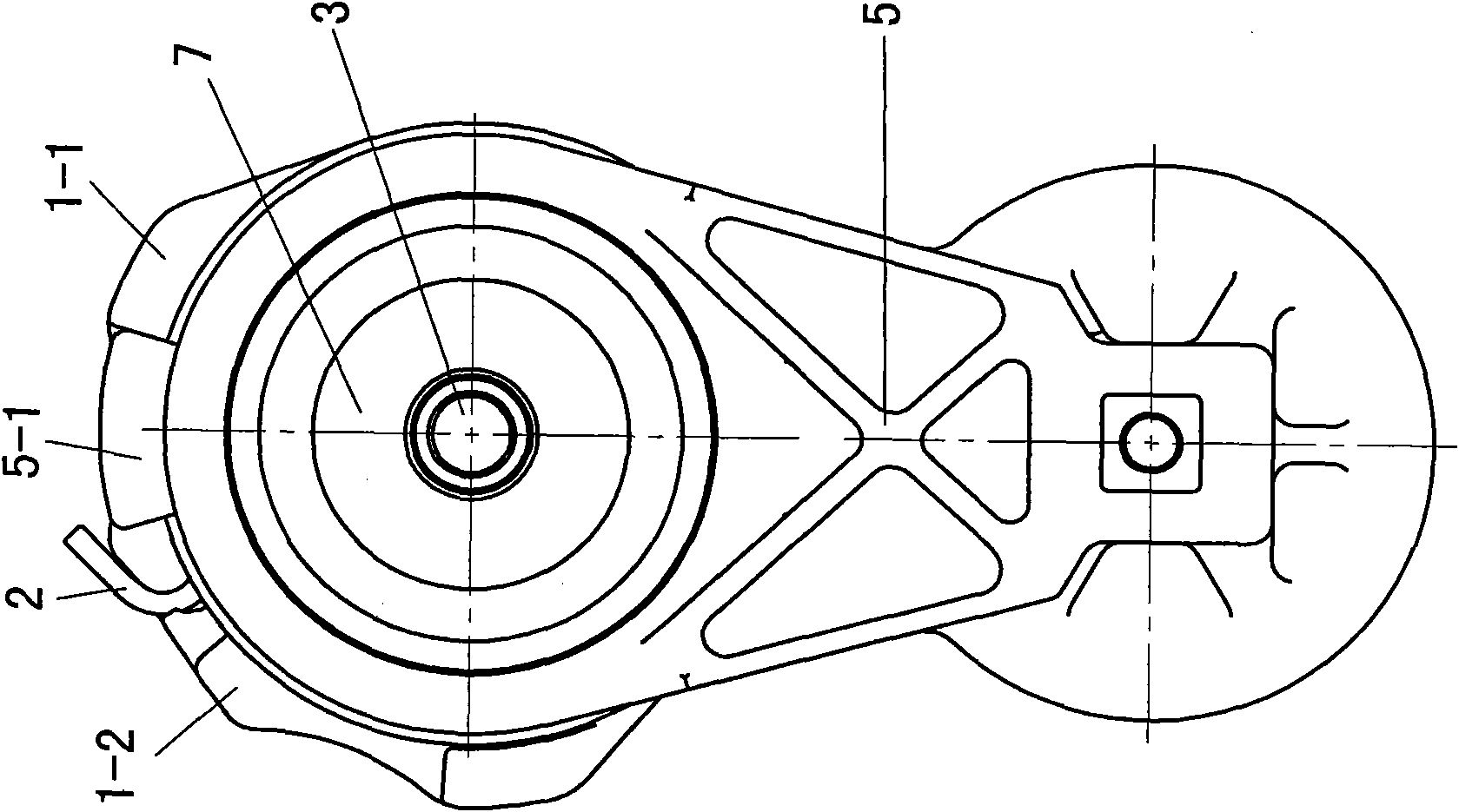

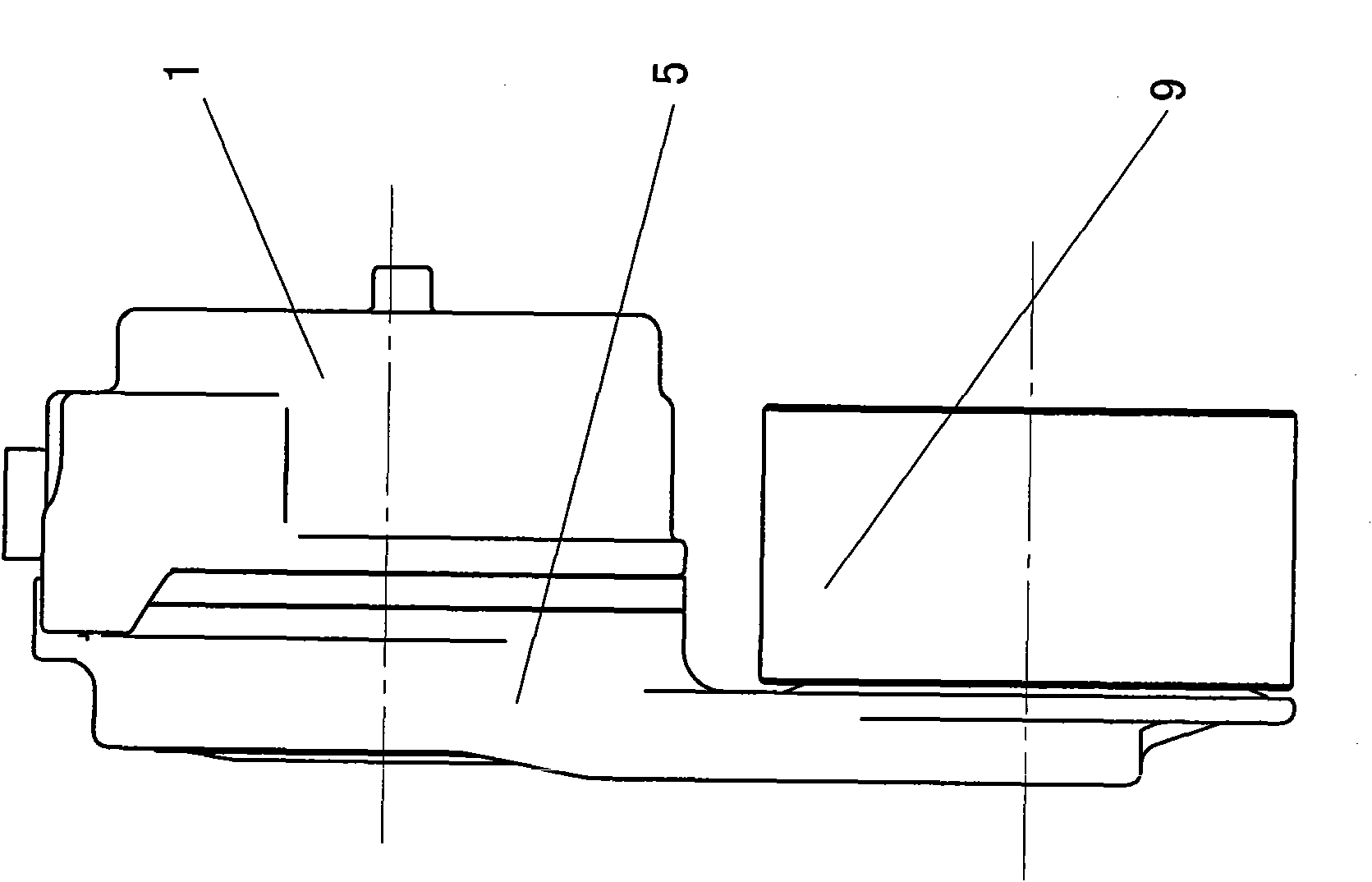

[0112] Combine Figure 1 to Figure 8 ,as well as Figure 18 , A total of 9 pictures for description. figure 1 It is a three-dimensional schematic diagram of the belt tensioning device of the automobile engine of the present invention, and the separation process is done in the figure; figure 2 It is the front view of the belt tensioning device of the automobile engine of the present invention; image 3 Yes figure 2 Right view Figure 4 Yes figure 2 The rear view; Figure 5 Is a picture with figure 2 The front view with the same visual direction, but with a partial cross-sectional processing; Image 6 Yes figure 2 The left view of, with a partial cross-sectional treatment in the figure; Figure 7 It is one of the schematic diagrams of the shape structure and connection relationship of the central axis, asymmetric damping block, elastic sheet, pushing structure, circular cavity, and circular wall; Figure 8 It is a three-dimensional schematic diagram of the cover, the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com