Magnetic head assembly and method of solder bonding

一种接合方法、磁头组件的技术,应用在焊接设备、焊接设备、激光焊接设备等方向,能够解决磁头滑块浮起特性即输出特性变差、滑块姿势变动等问题,达到抑制姿势变化、提高接合可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

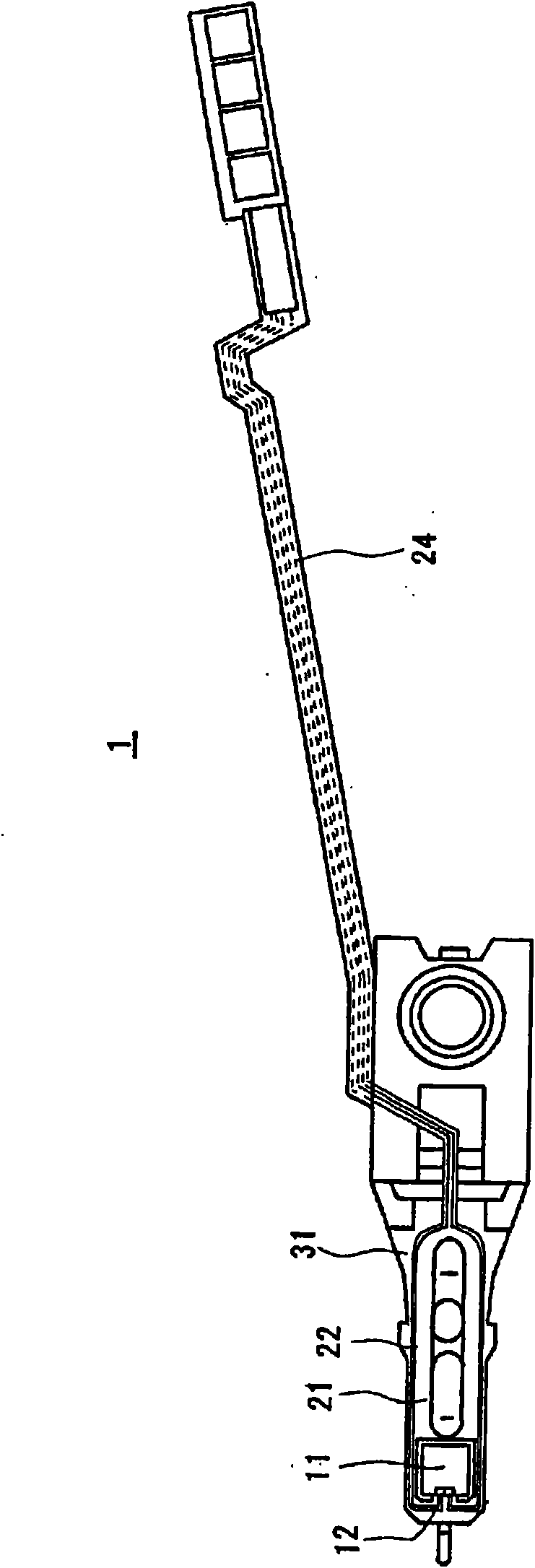

[0035] figure 1 An embodiment of a magnetic head assembly (completed state) for a hard disk drive to which the method of the present invention is applied is shown. The magnetic head assembly 1 includes a slider 11 incorporating a magnetoresistive effect element (magnetic head) 12, and a back surface of the slider 11 bonded by, for example, a thermosetting adhesive, a UV curable adhesive, or a conductive adhesive. flexible part 21.

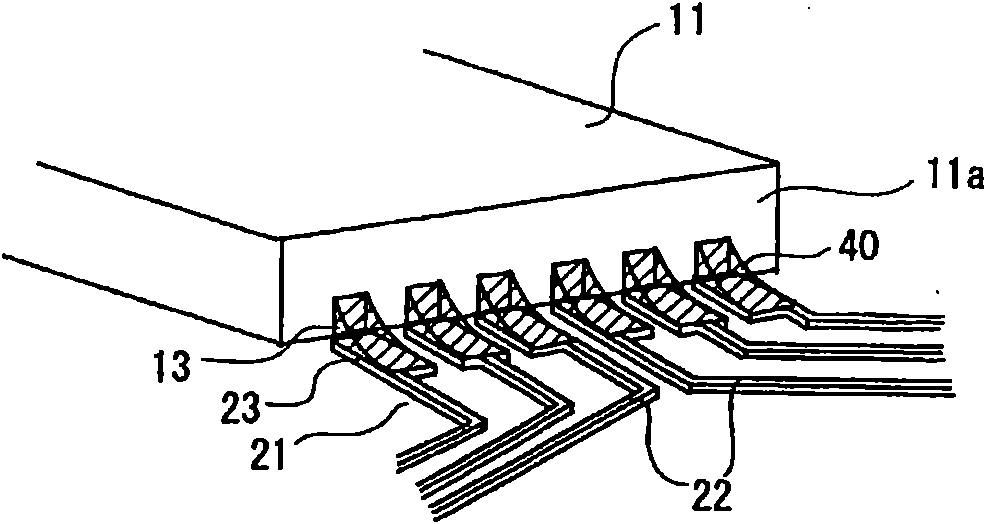

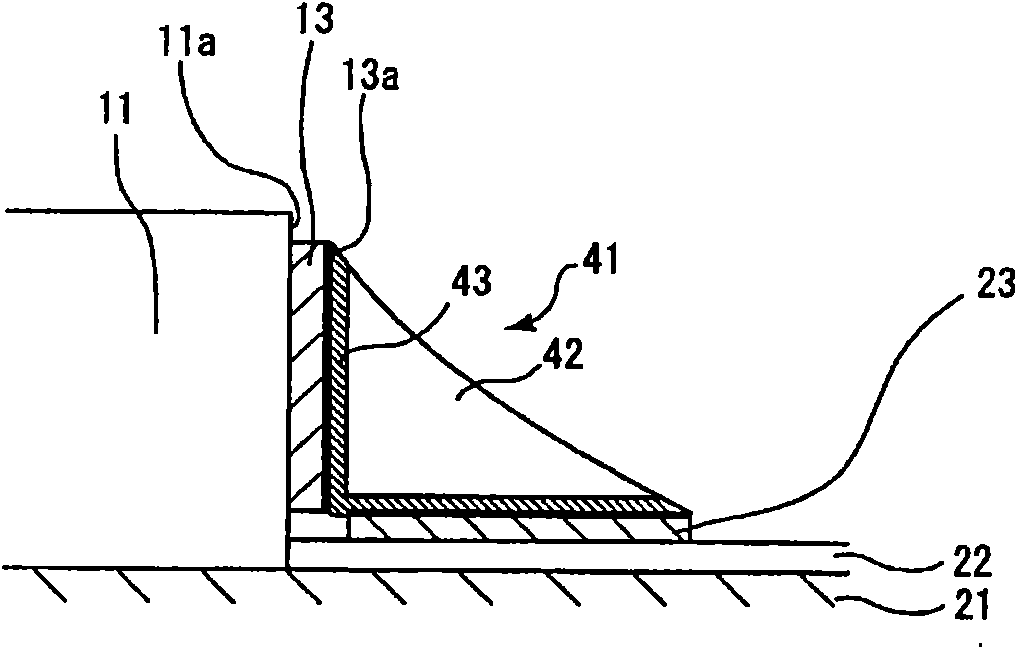

[0036] The flexible member 21 is a leaf spring-like flexible thin metal plate, and is attached to the front end of the load beam in a state where the slider 11 is elastically supported in suspension with respect to the load beam. On the surface of the flexible member 21, a flexible wiring board (FPC) 22 is fixed by pasting an adhesive or the like. The circuit system conduction connection. Flexible wiring substrate 22 such as figure 2 In an enlarged view, after being separated from a plurality of electrode pads 23 arranged on the front end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com