Heat treatment enhanced glass air cushion bed device

An air bed and glass technology, which is applied in glass production, glass tempering, glass manufacturing equipment, etc., can solve problems such as optical distortion, stress spots, scratches, etc., and achieve the effect of reducing poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

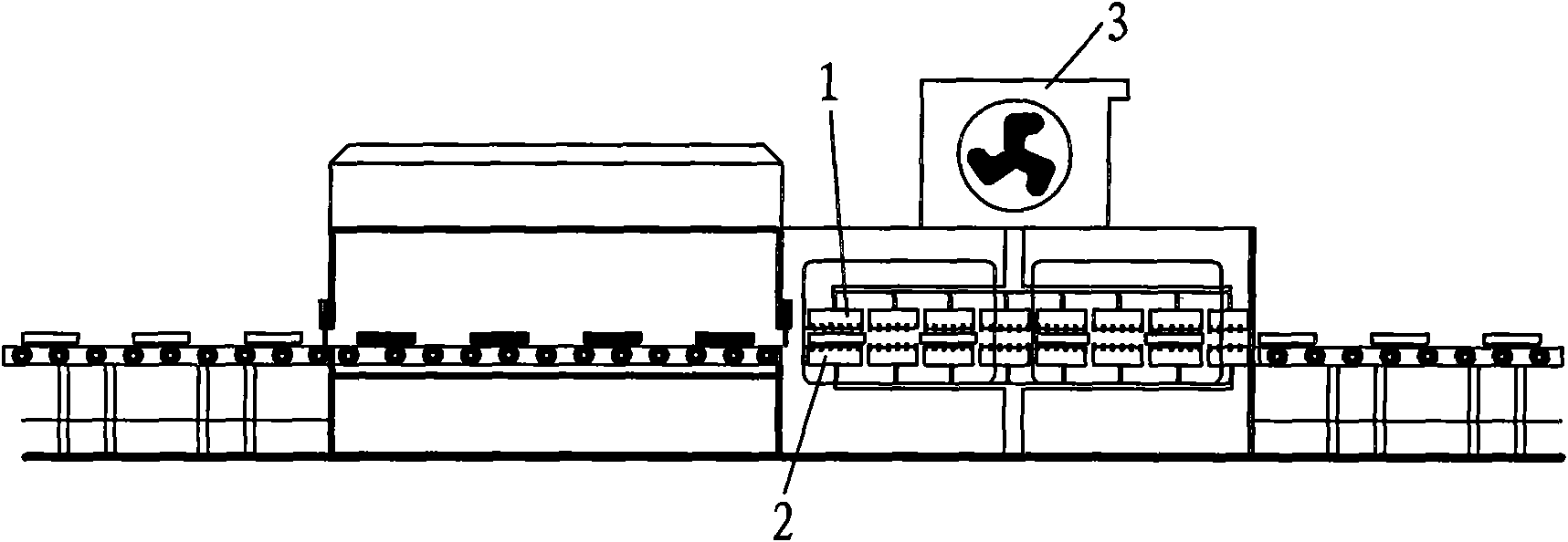

[0035] Such as figure 1 with Figure 7 As shown, an air cushion device is installed outside the hearth that is discharged after the heating hearth is heated. The air cushion device comprises an upper blowing device 1 and an air bed 2, wherein the inside of the upper blowing device 1 and the air bed 2 is a cavity, and each has an air inlet 31 connected to the air duct 32 of the fan 3, the air volume of the fan 3 Adjustable; the upper blowing device 1 and the air bed 2 are arranged parallel to each other up and down at a distance of 12, and the bottom surface of the upper blowing device 1 is parallel to the top surface of the air bed 2, and a number of air outlets 5 are evenly distributed on the two planes. A distance 12 is maintained between the two planes for the glass 6 to pass through.

[0036] The strong airflow input into the cavity of the air mattress 2 through the blower 3 passes through the dense small air outlets 5 to form a blowing airflow on the upper and lower pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com