Method for positioning steel reinforcement framework by replacing laminated rubber bearing on bridge abutment of road bridge

A plate type rubber bearing and steel skeleton technology, applied in bridges, bridge maintenance, bridge reinforcement and other directions, can solve the problems of long construction period, occupying large jacks and supporting tools, etc., and achieve the effect of short period and low construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

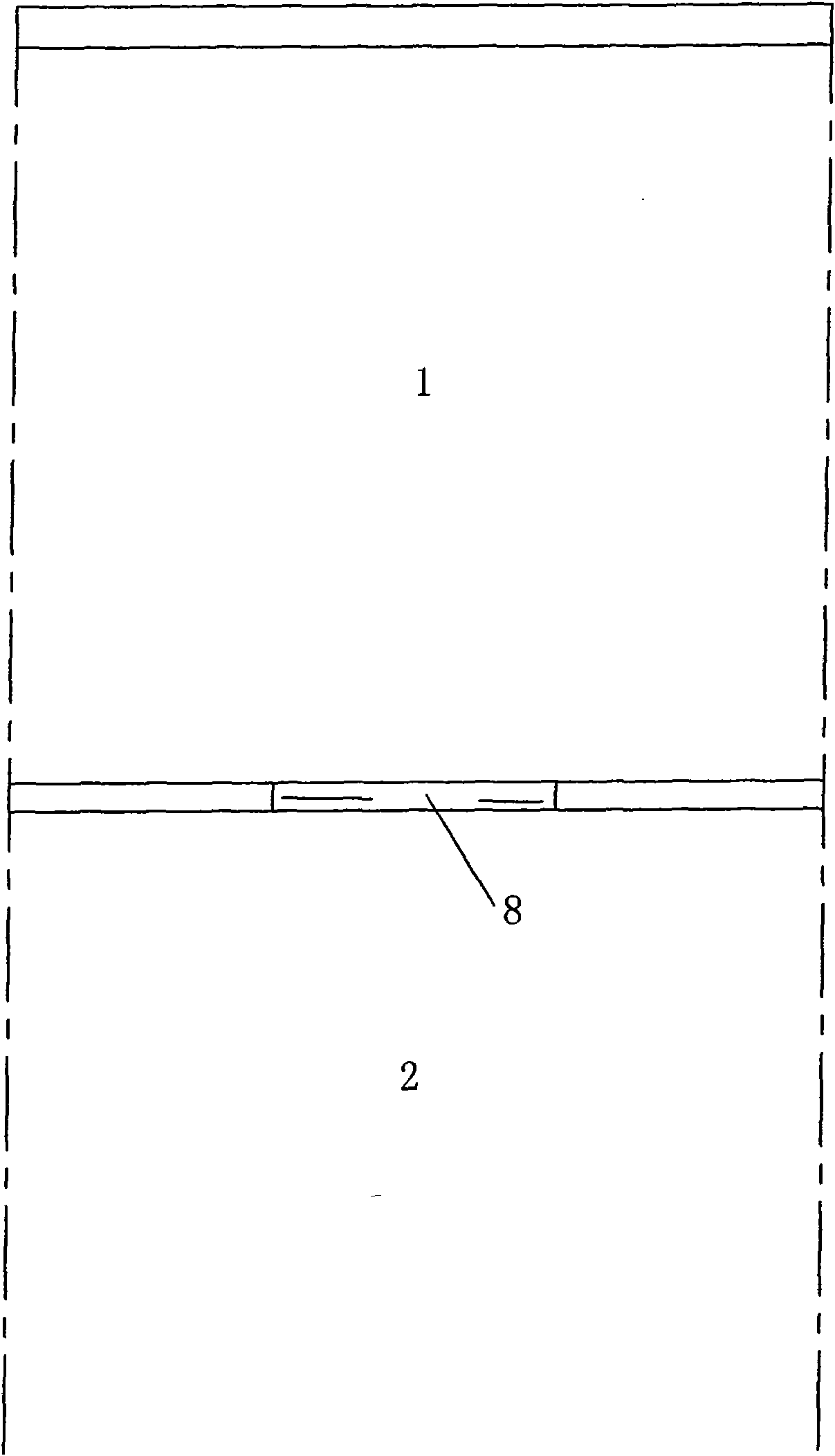

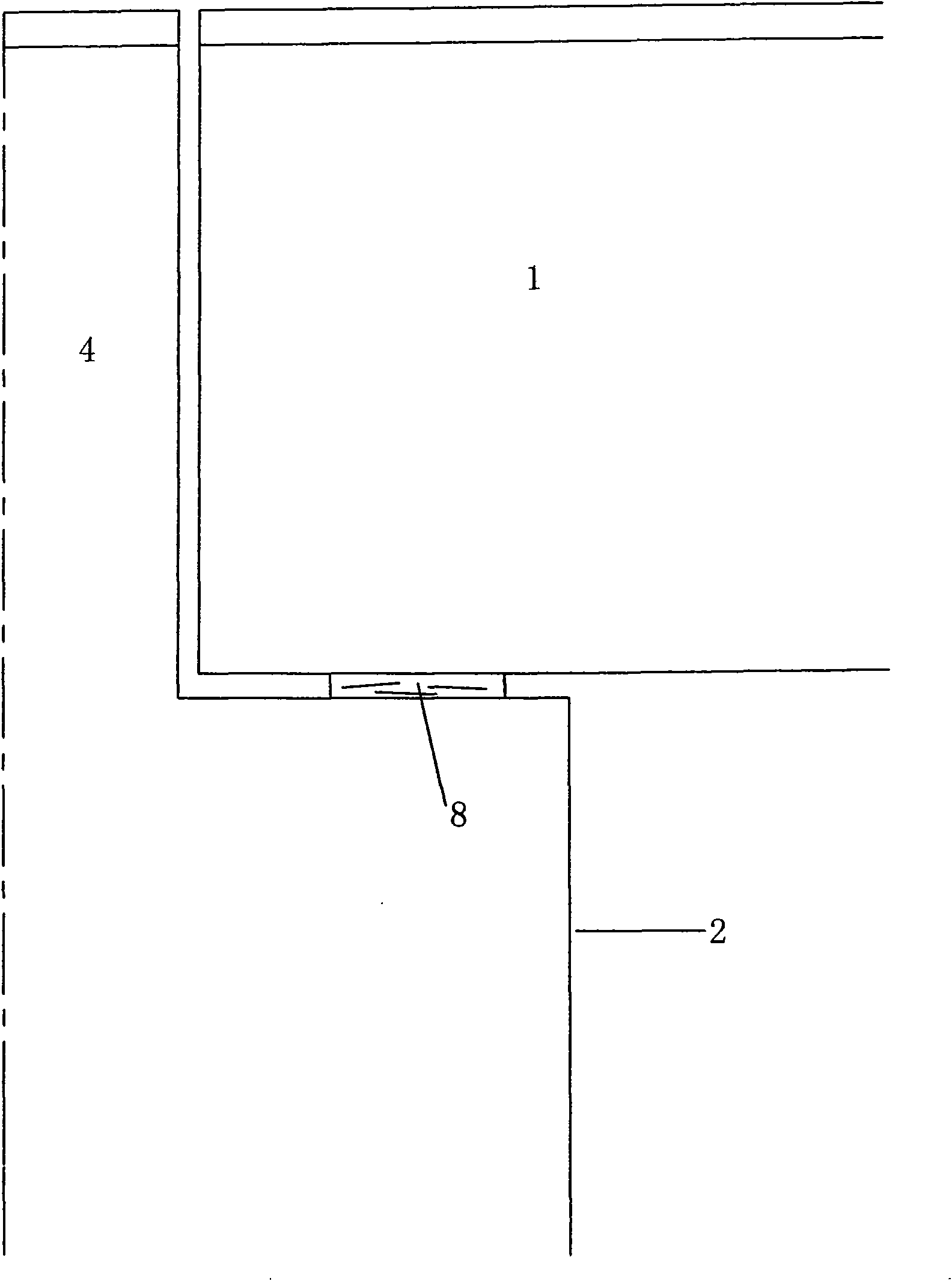

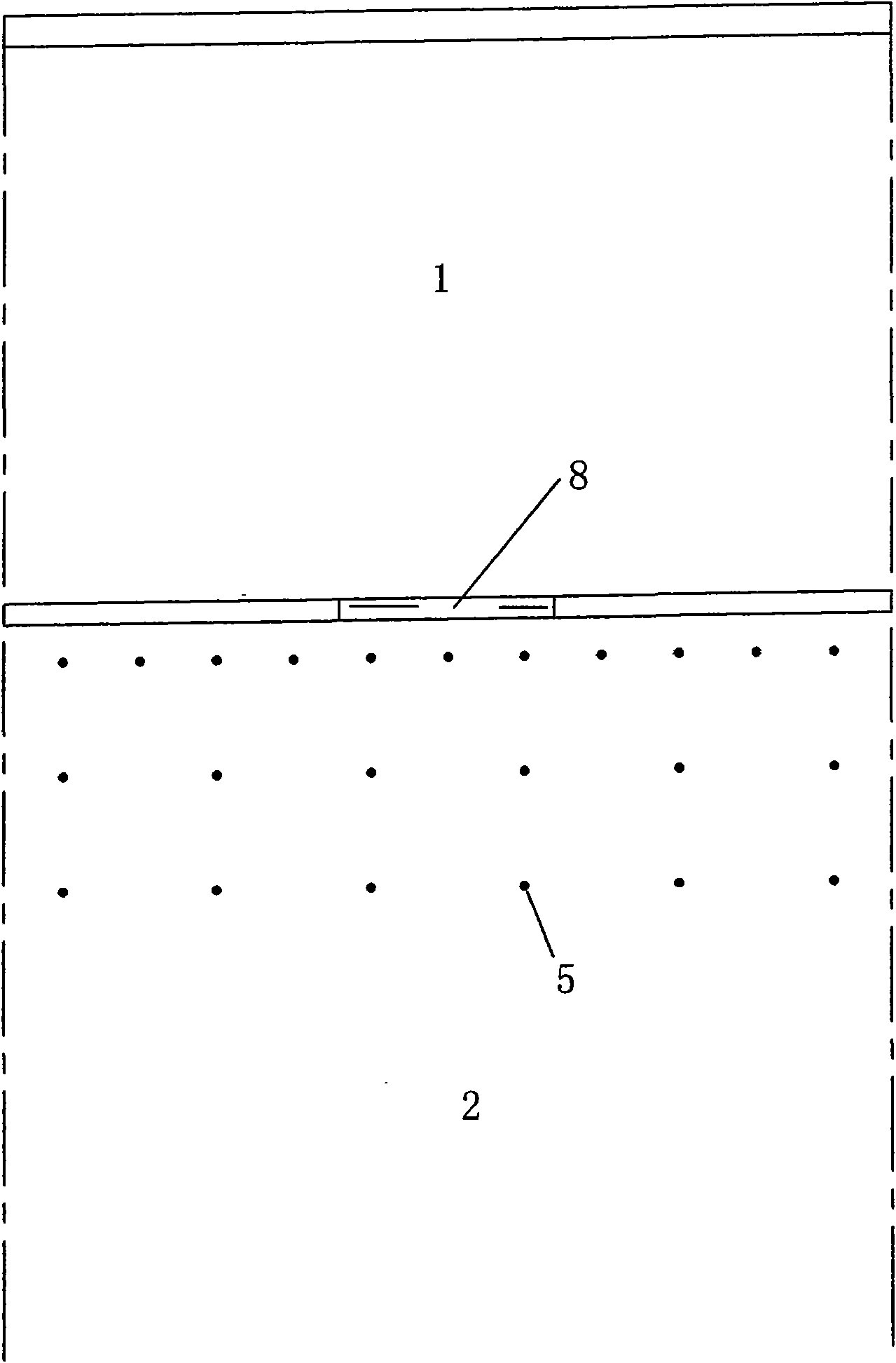

[0035] Adopt the present invention to replace the plate type rubber bearing on the highway bridge abutment, should according to Figure 1 to Figure 23 Step by step:

[0036] Firstly, an anchorage area is set on the top of the abutment, the old and new concrete in the collapsed part are consolidated together, the concrete in the cracked part is locked together, and support points and welding points are set up for the steel skeleton 12 of the new bearing foundation 16 to be installed. The anchor rod 5 in the anchorage area is made of Φ20 steel bar, and its length is equal to the width of the original abutment top surface, and its top is blade-shaped, and its tail end face is perpendicular to the axial direction of the anchor rod 5. All anchor rods 5 are driven horizontally along the longitudinal bridge, and their tops extend into the abutment backrest 4 within 20mm, and their tail ends are recessed into the abutment facade 2 within 20mm. The anchor hole is made with a pneumatic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com