Combined fireproof kitchen-toilet exhaust passage and method of producing same

A manufacturing method and exhaust duct technology, applied in the direction of manufacturing tools, vertical pipes, building components, etc., can solve the problems of pipe collapse, loss of strength, and blockage of pipes of residents on the ground floor, etc., to achieve improved fire resistance, simple structure, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

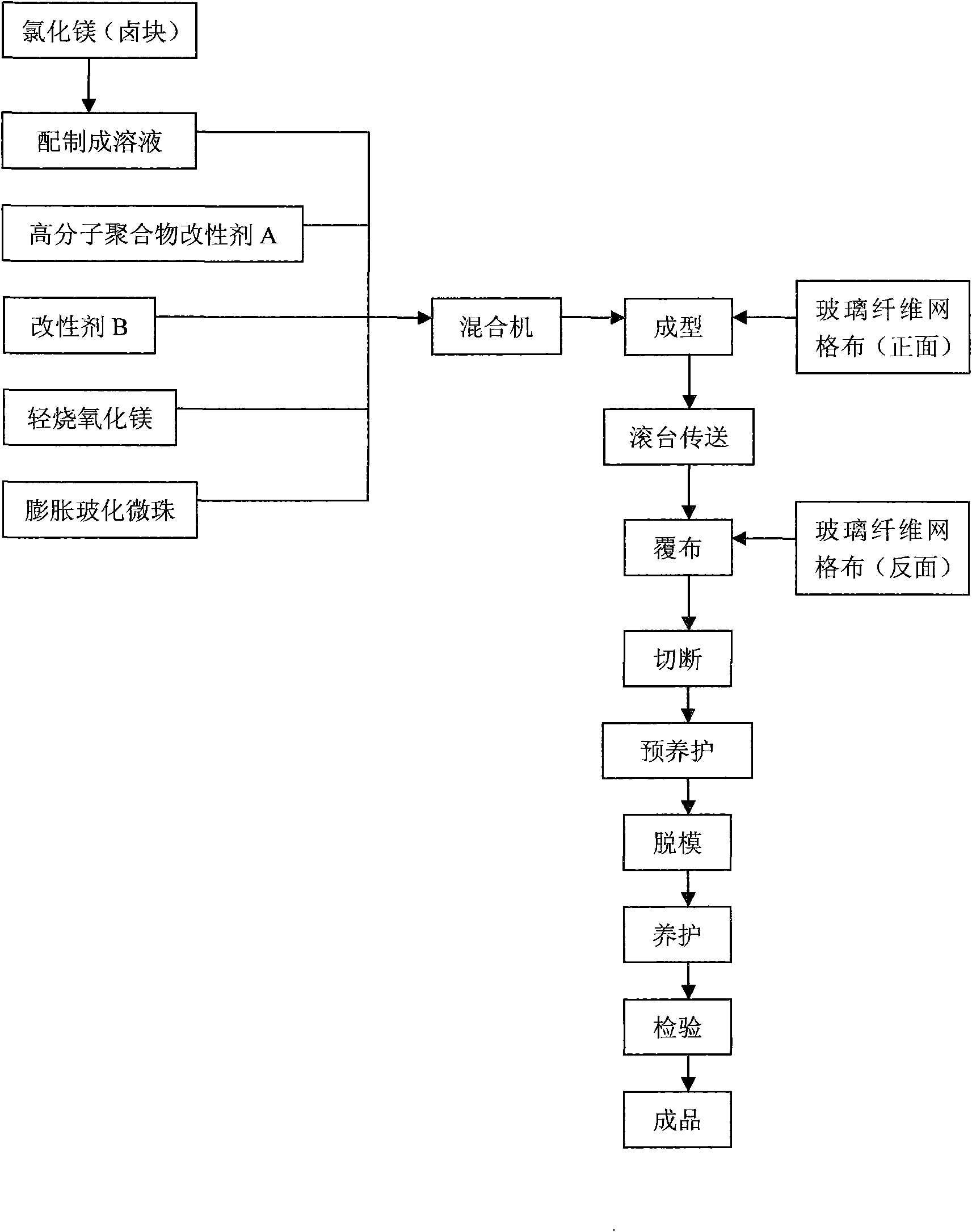

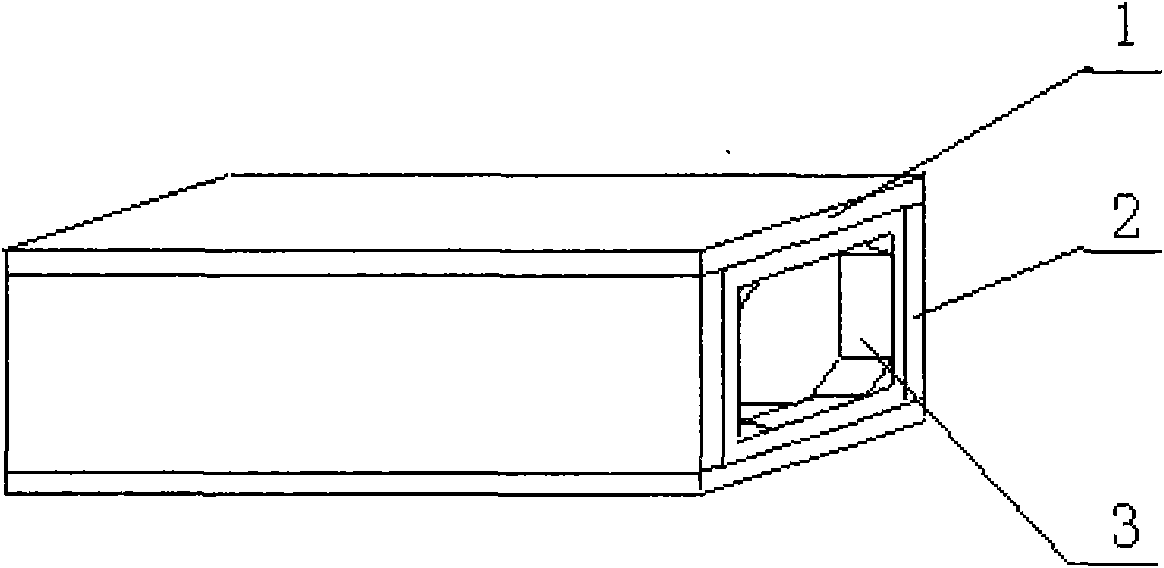

[0017] In the embodiment of the present invention, magnesium oxychloride material is used to produce a combined fireproof exhaust duct for kitchen and bathroom. The material formula of the embodiment of the present invention is: 100 kg of magnesium oxide, 60 kg of magnesium chloride, 40 kg of expanded vitrified microbeads, 2 kg of polymer A, and 1.5 kg of modifier B. Prepare the materials according to the above formula and put them into the mixer. After mixing evenly, enter the composite sheet forming machine to press into a sheet and coat it with glass fiber mesh cloth, and finally demould it. According to the above formula and process flow, the sizes of the two types of plates to be pressed are: 3000mm×250mm×7mm, 3000mm×236mm×7mm, each of which is produced in an even number of pieces; then according to the above formula and process flow, press the back shape on the special mold The inner frame and the cross-section are right-angled triangle strips. The size of the back-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com