Processing method for high-pressure water-enriched filling karst cavity

A treatment method and technology for dissolving cavities, applied in the field of high-pressure water-rich filling dissolving cavities, can solve problems such as grouting blind areas or freezing blind areas, water inrush, mud inrush, hidden dangers in tunnel construction, etc., so as to improve safety. and reliability, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

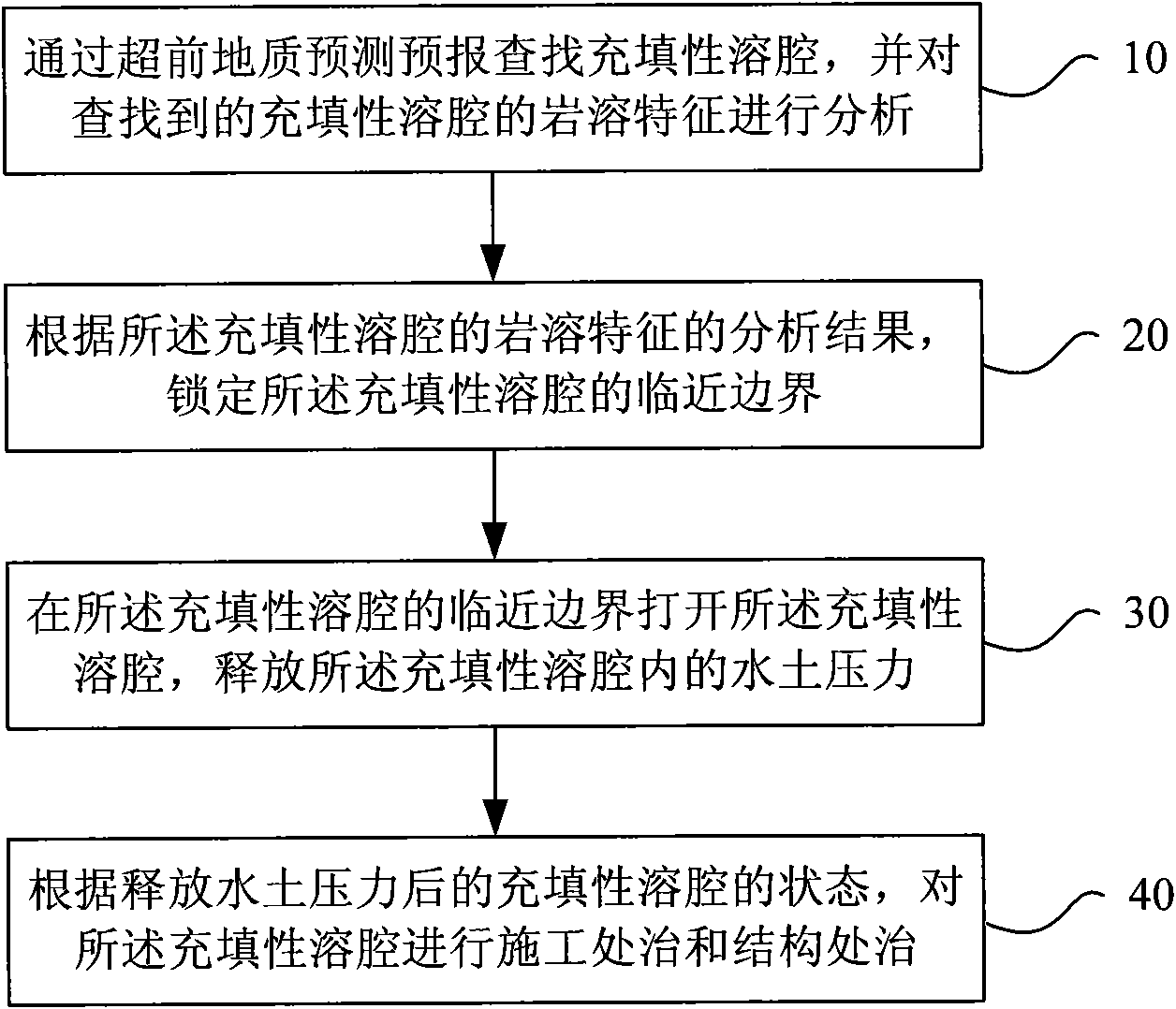

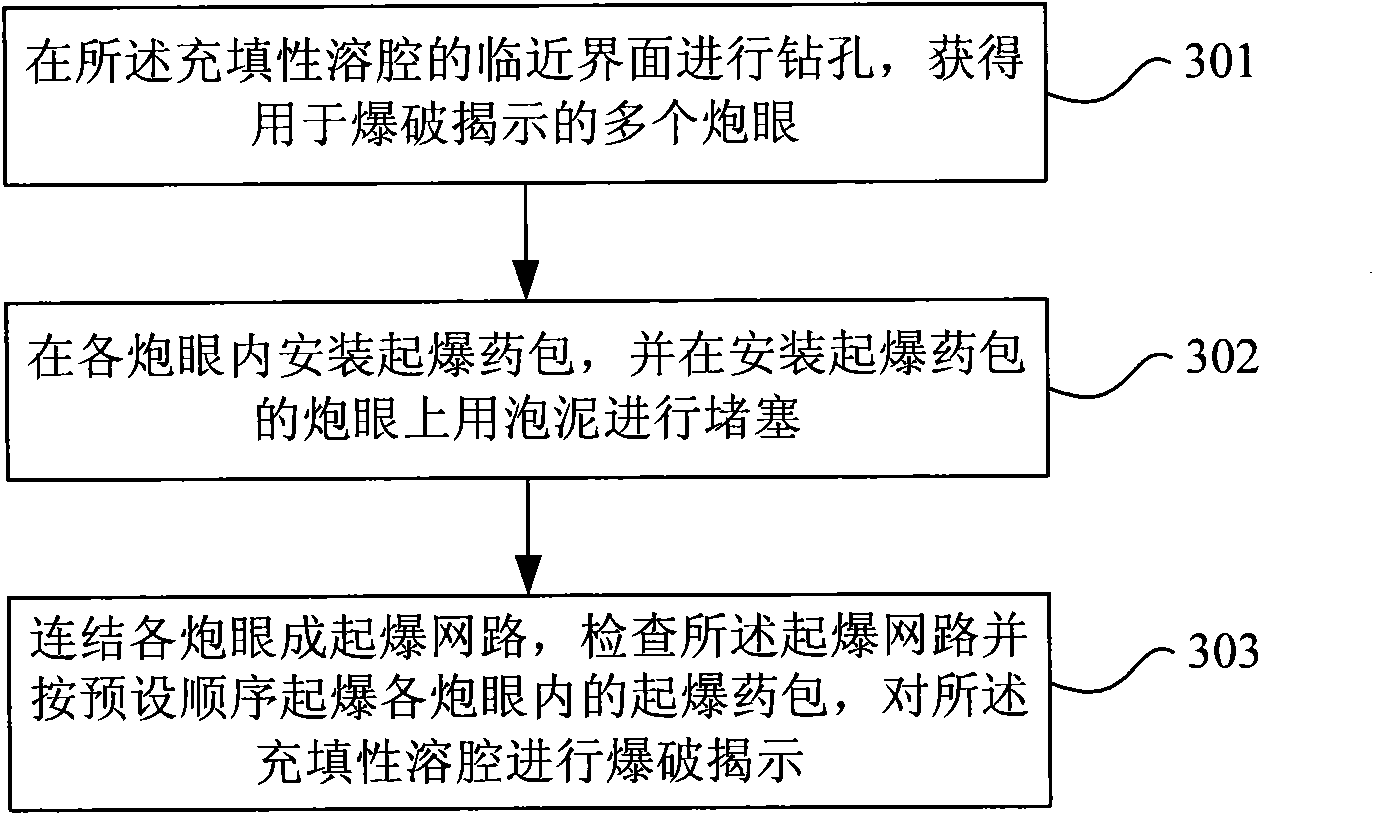

[0029] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0030] The embodiment of the present invention can be applied to tunnel construction under karst landform conditions to treat filling karst cavities, especially to release energy and reduce pressure for high-pressure water-rich filling karst cavities, releasing the water and soil pressure stored in filling karst cavities energy, reduce the impact of water and soil pressure in the filled dissolved cavity on the project during tunnel construction and operation, prevent water and mud inrush, and at the same time ensure the safety and reliability of tunnel construction and improve tunnel construction s efficiency. Specifically, the embodiment of the present invention is described by taking the treatment process of the high-pressure water-rich water-filled dissolution cavity during tunnel construction as an example.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com