Refrigerating ball valve and manufacturing process thereof

A manufacturing process and ball valve technology, applied in the direction of valve operation/release device, valve details, valve device, etc., can solve the problems of gaskets being easy to melt, unable to repair, aging, etc., and achieve quality assurance, convenient maintenance, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

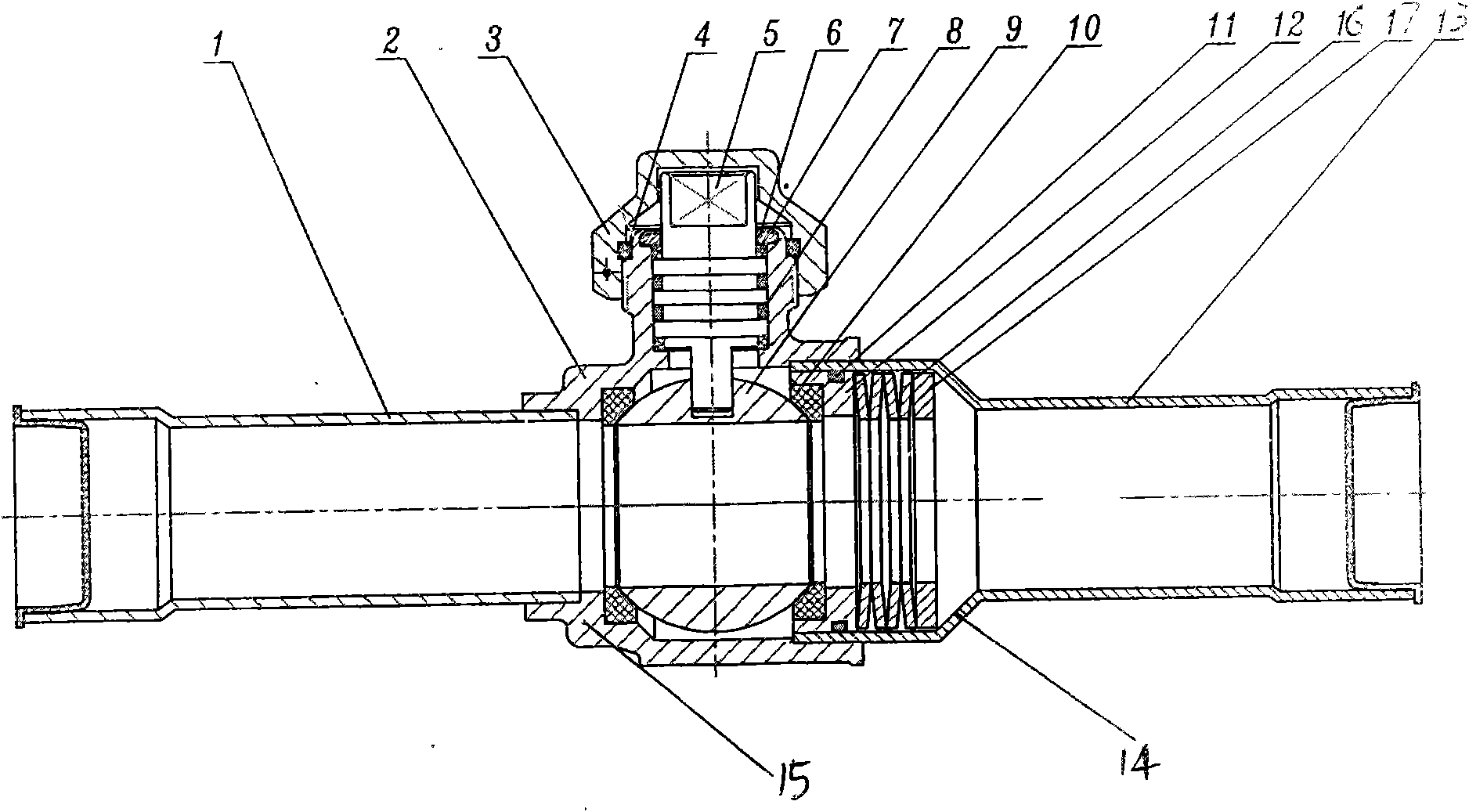

[0010] As shown in the figure, the present invention is mainly composed of a valve body 2 and a valve seat 10 arranged in the valve body 2. A sealing ball 9 is arranged in the valve seat 10, and a rotary rod 5 is arranged on the sealing ball 9. 2 is provided with a cap 3, the rotary rod 5 is in the cap 3, an O-ring 4 is provided between the cap 3 and the valve body 2, an O-ring 8 is provided between the rotary rod 5 and the valve body 2, and an O-ring 8 is provided between the rotary rod 5 and the valve body 2. In the cap 3, a gasket 6 and a rotary rod liner 7 are also arranged between the cover 3 and the rotary rod 5, and the two sides of the valve body 2 are provided with joints 15, 12, and the joint 15 is provided with internal threads, and is provided with The externally threaded connecting pipe is screwed in phase 1, compressed with a nut, and fixed by argon arc welding. The joint 12 is connected with the connecting pipe 13, and a necking 14 is provided at the connection,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com