Novel air vent structure for crude cave house and construction process thereof

A raw earth kiln dwelling and ventilation hole technology, which is applied in the ventilation system, building structure, space heating and ventilation, etc., can solve the problems such as the ventilation hole structure without ventilation system design, and achieve the improvement of living comfort and material extraction. Simple, easy-to-produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

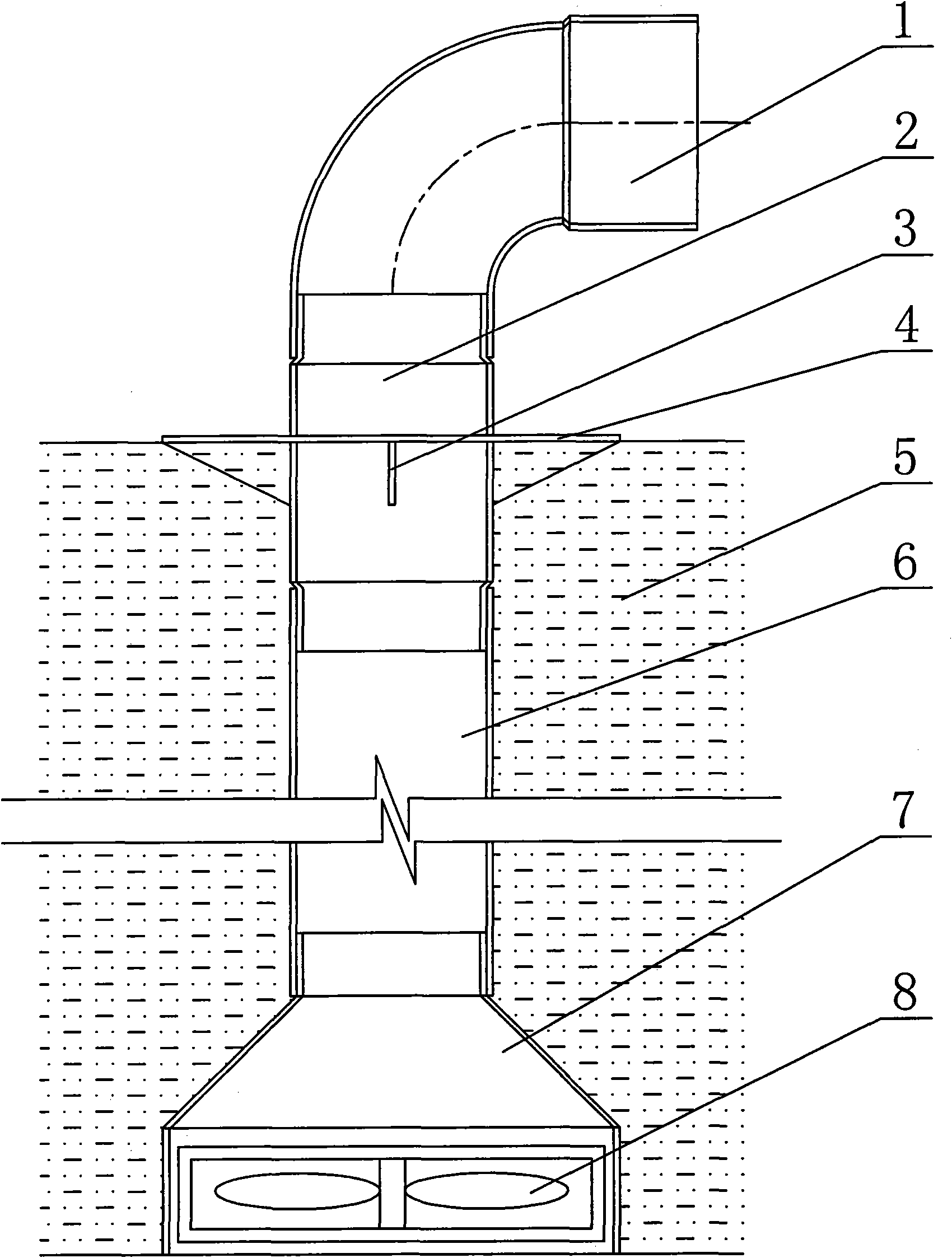

[0031] Such as figure 1 As shown, the overburden layer 5 is provided with an elbow 1, and the overburden layer 5 is provided with a connecting pipe 2, a straight pipe 6 and a trumpet pipe 7. The elbow 1 and the straight pipe 6 are connected by the connecting pipe 2, and the lower end of the straight pipe 6 is provided with a Trumpet pipe 7 and exhaust fan 8 are arranged in the trumpet pipe 7, flange 4 is arranged on connecting pipe 2, and reinforcing rib 3 is arranged under flange 4. In this embodiment, elbow pipe 1, connecting pipe 2 and straight pipe 6 The inner diameter of the pipe is 160mm, the pipe wall thickness is 5mm, the height of the elbow 1 is 300mm, the extension length of the flange 4 is 100mm, the height of the rib 3 is 80mm, and the thickness of the flange 4 and the rib 3 is 5mm. The specific construction process steps for:

[0032] The first step, forming the ventilation holes in the covering soil layer 5:

[0033] a. Select the location of the ventilation ho...

Embodiment 2

[0048] Repeat Example 1, with the following differences: the internal diameter of all pipes is 140mm, the pipe wall thickness is 5mm, the height of the elbow 1 is 280mm, the overhang of the flange 4 is 80mm, the height of the rib 3 is 65mm, the flange 4 and the reinforcement Rib 3 thickness is 5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overhang | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com