Method for online calibrating perforated plate-type steam flow measurement system

A technology of steam flow and measurement system, which is applied in the calibration field of steam flow measurement system, which can solve the problems of troublesome disassembly of orifice plate, increase of production cost, inspection and maintenance of orifice plate, and achieve the effect of fast calibration, improved accuracy and intuitive data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Take the calibration of steam flow detection points in the raw silk section of Guiyang Cigarette Factory as an example:

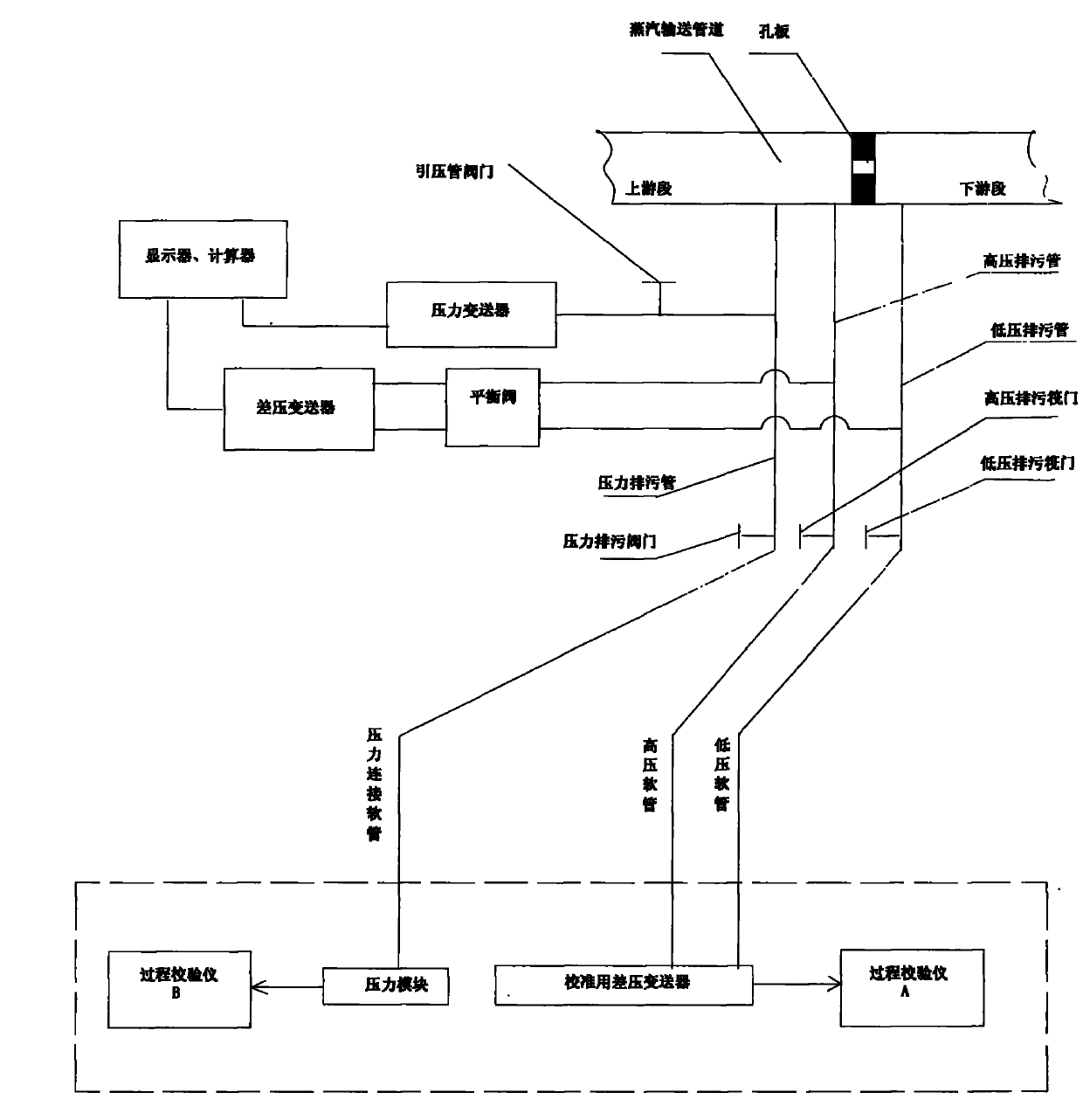

[0016] An online calibration method for an orifice-plate steam flow measurement system, comprising the following steps:

[0017] (1) Open the balance valve on the balance valve of the orifice steam flow measurement system to make the high and low pressure ends equal;

[0018] (2) Close the high-pressure end valve and low-pressure end valve on the balance valve, respectively open the pressure sewage valve, high-pressure sewage valve and low-pressure sewage valve to discharge sewage, and close the above three valves after the sewage discharge is completed;

[0019] (3) The differential pressure calibration module consists of a high-pressure hose, a low-pressure hose, a differential pressure transmitter for calibration, and a process calibrator A. One end of the high-pressure hose is connected to the high-pressure input port of the differential pressure...

Embodiment 2

[0036] Take the calibration of steam flow detection points in the raw silk section of Guiyang Cigarette Factory as an example.

[0037] The online calibration method of the orifice-plate steam flow measurement system is the same as that in Embodiment 1.

[0038] According to the "Calculation Book" of the design unit, it is found that k=0.4056937.

[0039] The test data is as follows (the units in the table are different, and the working ranges of the representative pressure and differential pressure are different):

[0040]

[0041] Check the saturated steam density table:

[0042] When the absolute pressure is 1.201020MPa, the saturated steam density is 6.132;

[0043] When the absolute pressure is 1.227891MPa, the saturated steam density is 6.264.

[0044] Through interpolation calculation, it can be obtained that when the relative pressure is 1.121MPa and the absolute pressure is 1.2104MPa, the saturated steam density is 6.178.

[0045] Substitute the differential pr...

Embodiment 3

[0048] Take the calibration of steam flow detection points in the fermentation section of Guiyang Cigarette Factory as an example:

[0049] The online calibration method of the orifice-plate steam flow measurement system is the same as that in Embodiment 1.

[0050] According to the "Calculation Book" of the design unit, it is found: k=0.4918.

[0051] The test data is as follows (the units in the table are different, and the working ranges of the representative pressure and differential pressure are different):

[0052]

[0053] Check the saturated steam density table:

[0054] When the absolute pressure is 0.5021MPa, the saturated steam density is 2.679;

[0055] When the absolute pressure is 0.515535MPa, the saturated steam density is 2.747.

[0056] Through interpolation calculation, when the relative pressure is 0.423MPa and the absolute pressure is 0.5124MPa, the saturated steam density is 2.7311.

[0057] Substitute the differential pressure 0.571kpa, density 2.731...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com