Electric arc furnace end point carbon content prediction method

A technology of end-point carbon content and prediction method, applied in electric furnaces, furnaces, furnace types, etc., can solve the problems of large differences in carbon quality, affecting end-point carbon control, inaccurate weighing of molten steel in electric arc furnaces, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

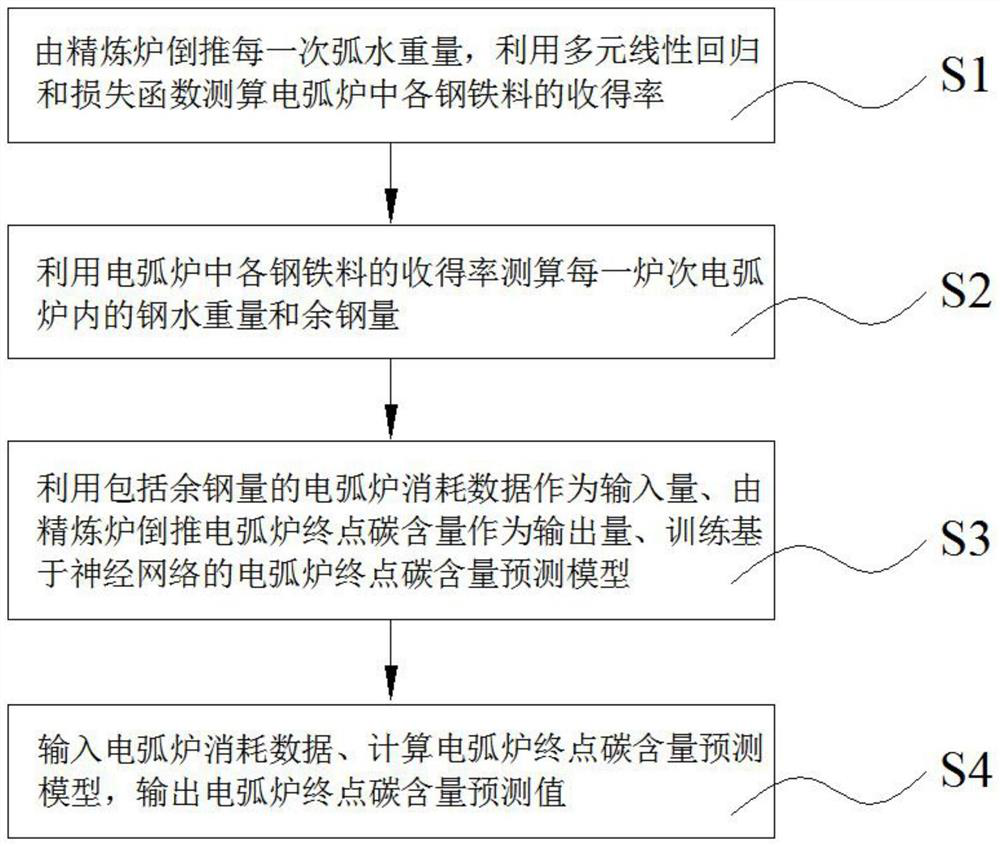

[0029] Such as figure 1 As shown, it is a preferred embodiment of the method for predicting carbon content at the end point of the electric arc furnace of the present invention, the method includes:

[0030] S1: Calculate the weight of molten steel in each batch of electric arc furnace from the refining furnace, and use multiple linear regression and loss function to calculate the yield of each steel material in the electric arc furnace;

[0031] Specifically: Step S1 includes the following steps:

[0032] S101: Based on the weighed weight of the refining furnace minus the weight of the ladle, the weight of raw and auxiliary materials added in the process from the electric arc furnace to the refining furnace in the steelmaking PES system is reversed to deduce the weight y of molten steel in the electric arc furnace for each heat;

[0033] S102: EAF smelting mainly uses molten iron and steel scrap for smelting, and there are many types of scrap steel. It is necessary to add su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com