Model and method for measuring resistance of contact holes or through holes in bipolar transistor components

A bipolar transistor and measurement model technology, which is applied in semiconductor/solid-state device testing/measurement, electric solid-state devices, semiconductor devices, etc., can solve problems such as large errors and inability to accurately measure the resistance value of the contact layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

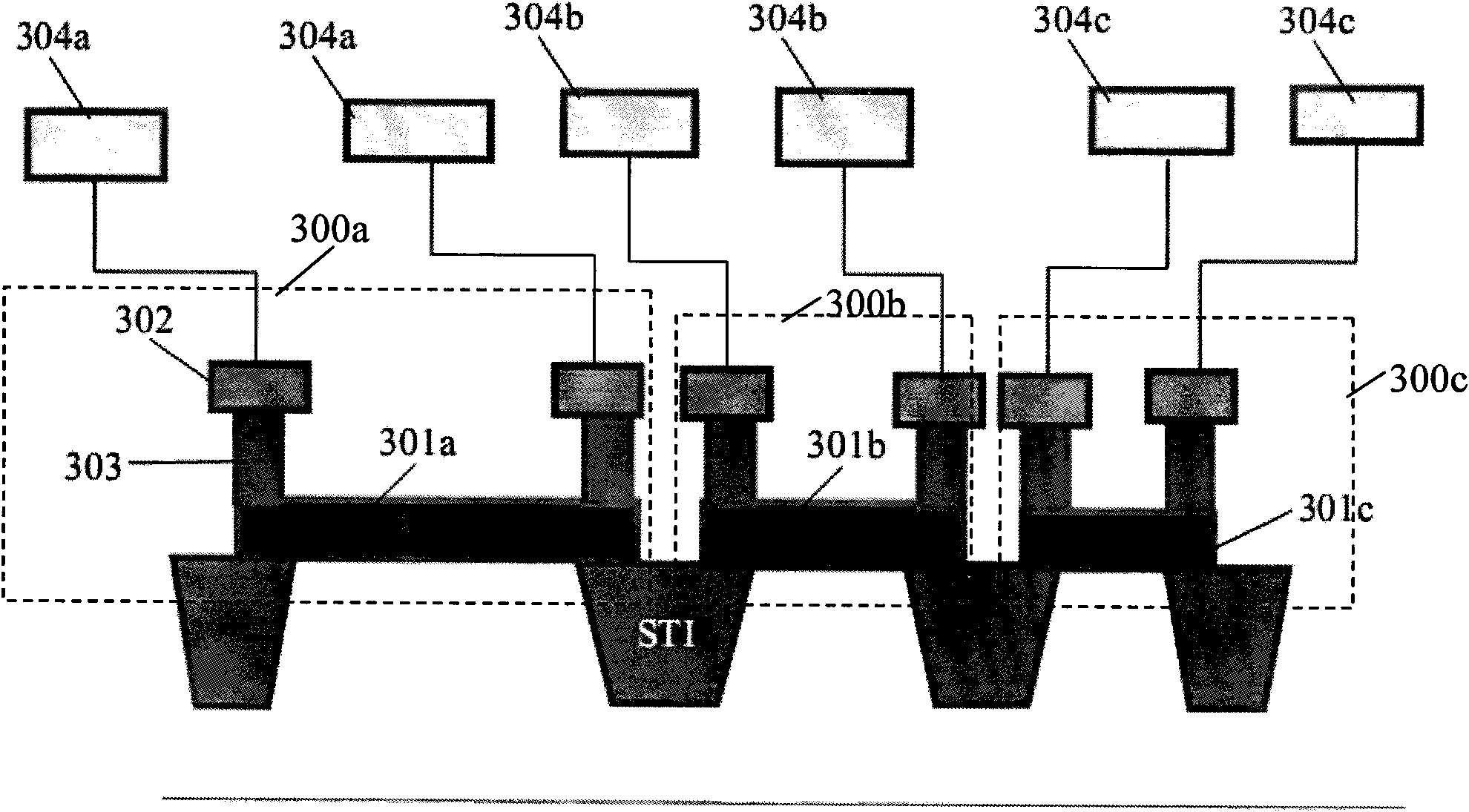

[0028] image 3 Shown is a measurement model for measuring the resistance value of a contact hole in a preferred embodiment of the present invention.

[0029] Different from the method of measuring the total resistance value flowing through a plurality of contact holes and then averaging in the prior art, this embodiment measures the resistance of resistance devices with different widths (W) and lengths (L) multiple times, and fits the corresponding curves, The intercept of the curve is the resistance of the contact hole.

[0030] image 3 Other structures of the medium-resistance device, such as P-well, STI isolation, etc., will not be described here one by one. In this embodiment, a plurality of resistance devices 300a-300c are included, and each resistance device 300a-300c includes polysilico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com