Coordination control system of double metal spiral compound pipe molding and welding

A coordinated control system and coordinated control technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

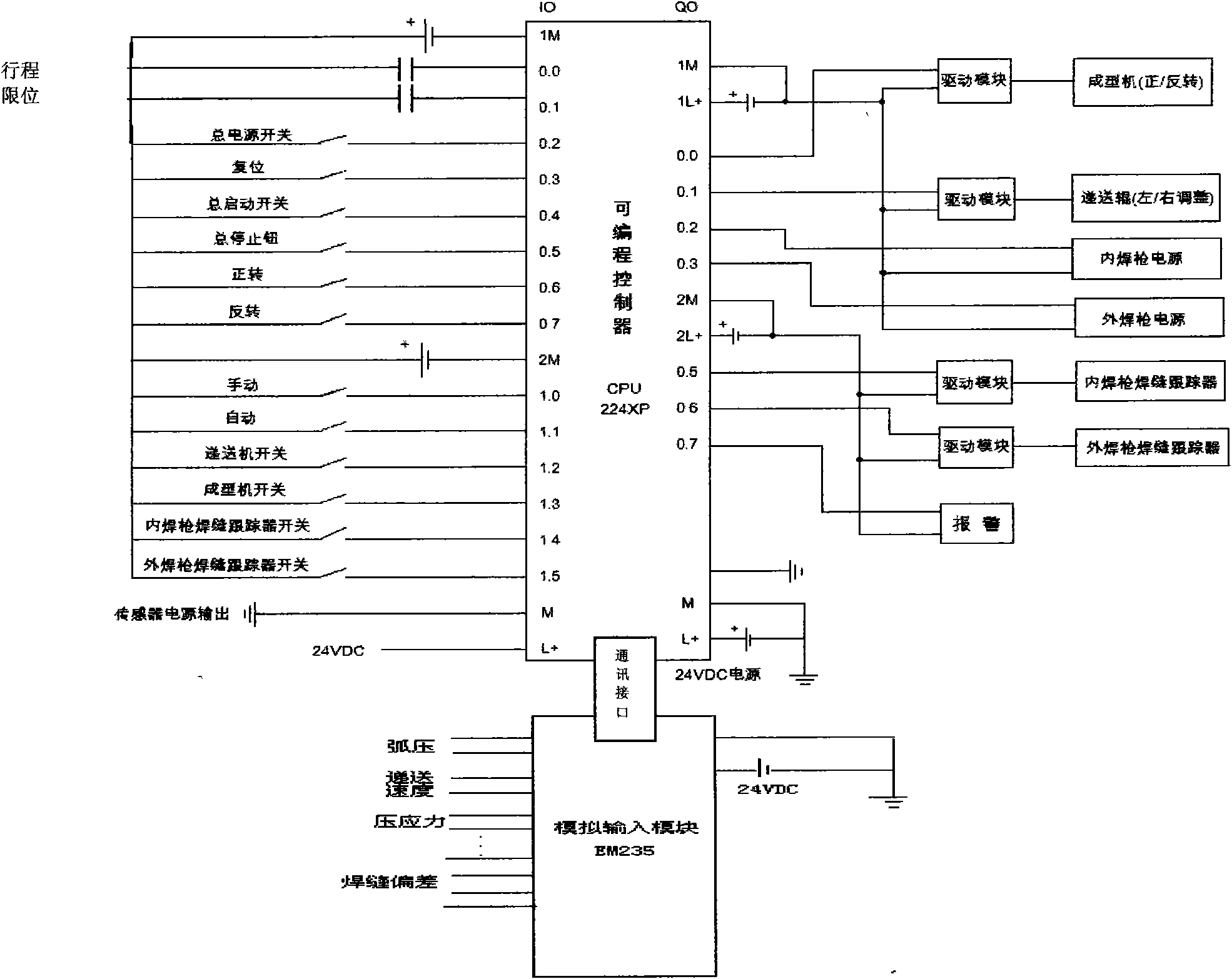

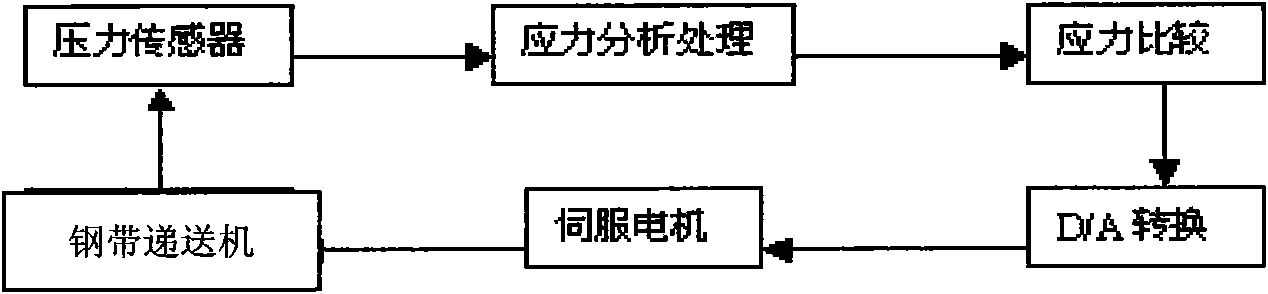

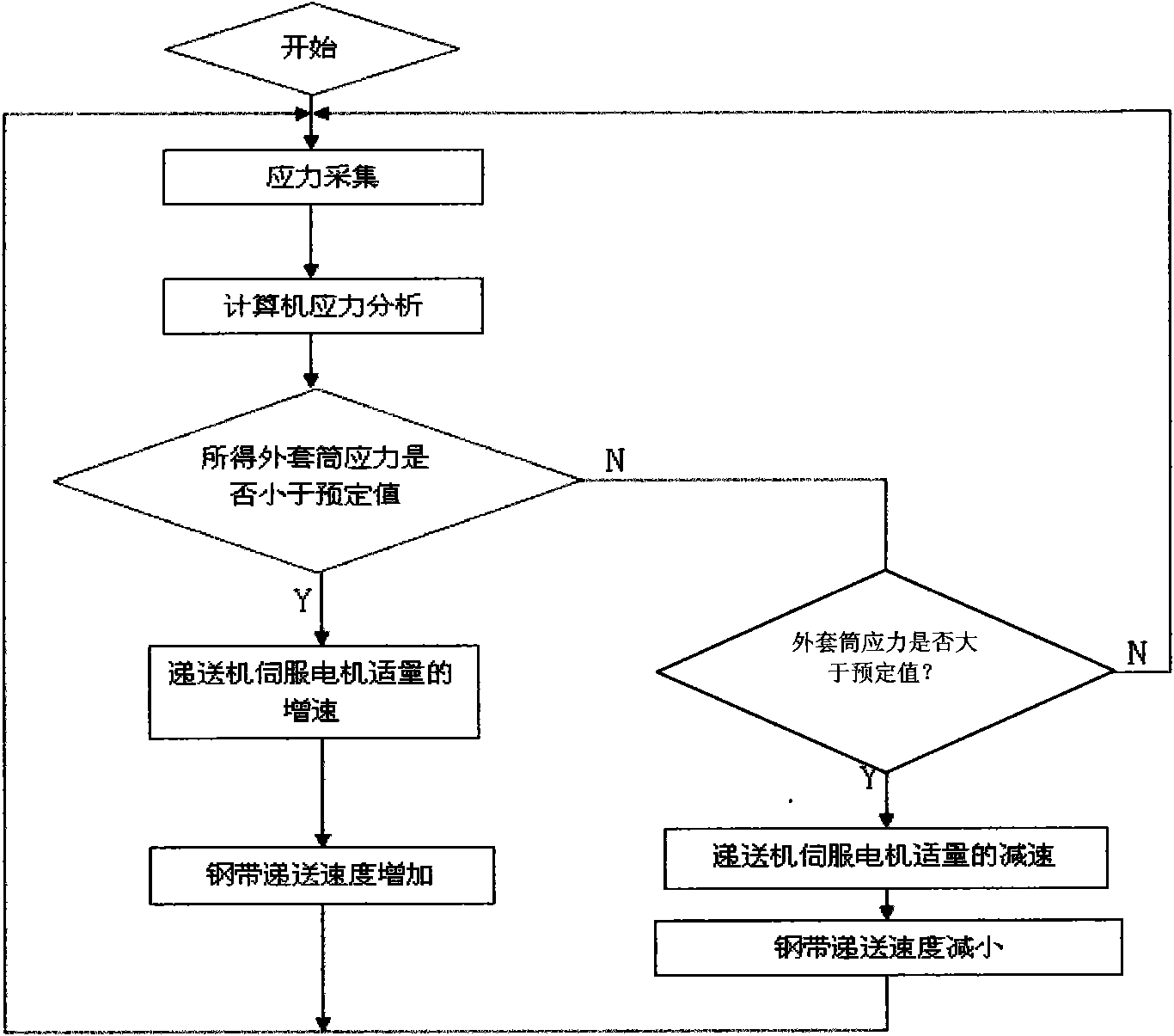

[0029] Depend on figure 1 It shows that the overall coordinated control system of the present invention is a coordinated control system for the forming and welding of bimetallic spiral composite pipes, which mainly includes: an overall coordinated control system 1, a coordinated control subsystem 2 for steel strip delivery and forming machine operation, internal and external welding torches and Shielding gas opening and closing coordination control subsystem 3, coordination control subsystem 4 of welding speed and steel strip forming speed, and welding seam tracking and welding quality control subsystem 5, wherein: the overall coordination control system 1 adopts programmable The controller PLC, as the main controller of the upper computer, coordinates the subsystems overall, and is connected with the forming machine, the delivery machine and the internal and external welding torch seam tracker through the drive module. The overall coordination control system is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com