Combined ventilator/gas valve unit

A ventilator and gas valve technology, applied in the field of gas heating equipment, can solve the problems of long tolerance chain, poor reliability, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

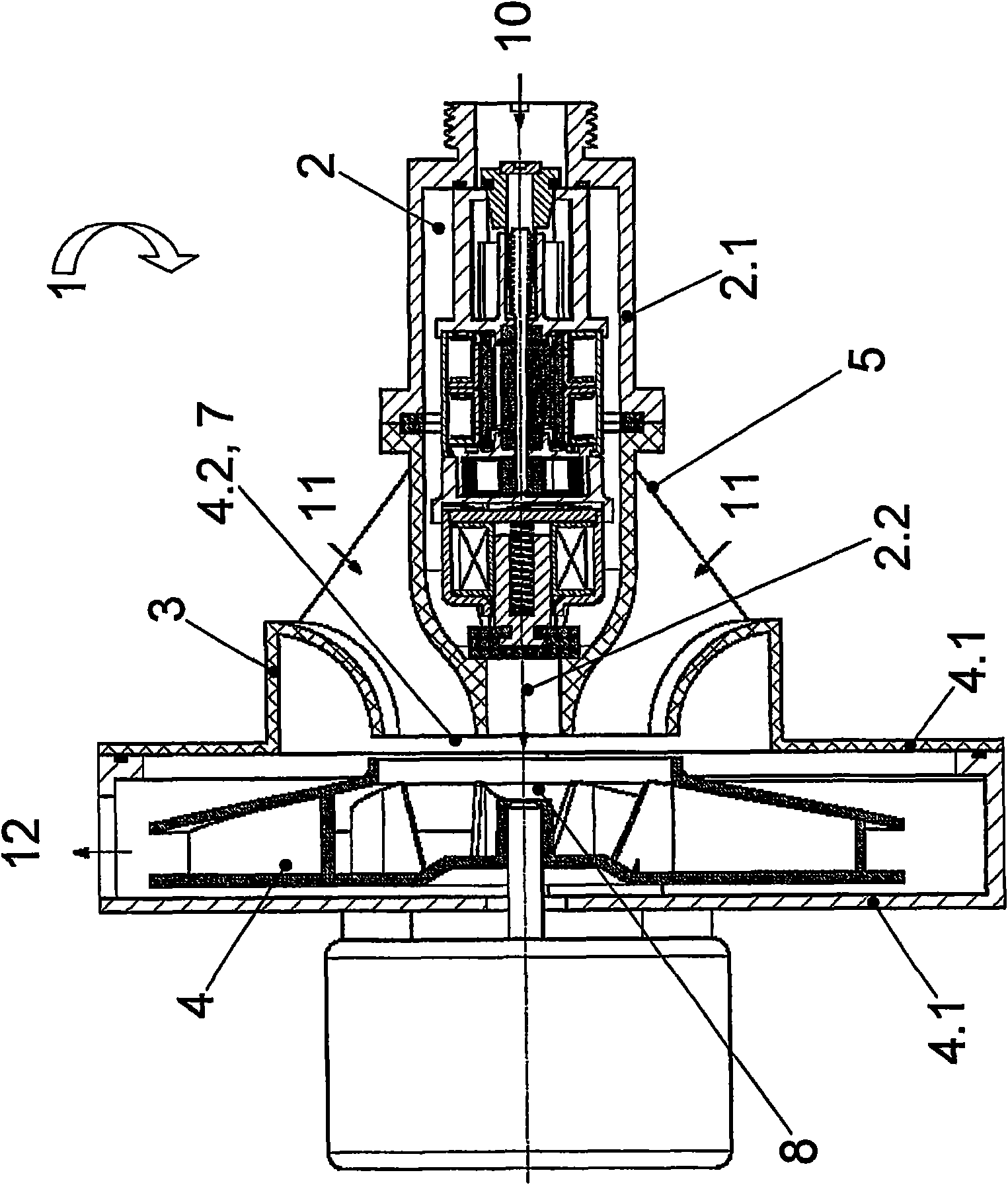

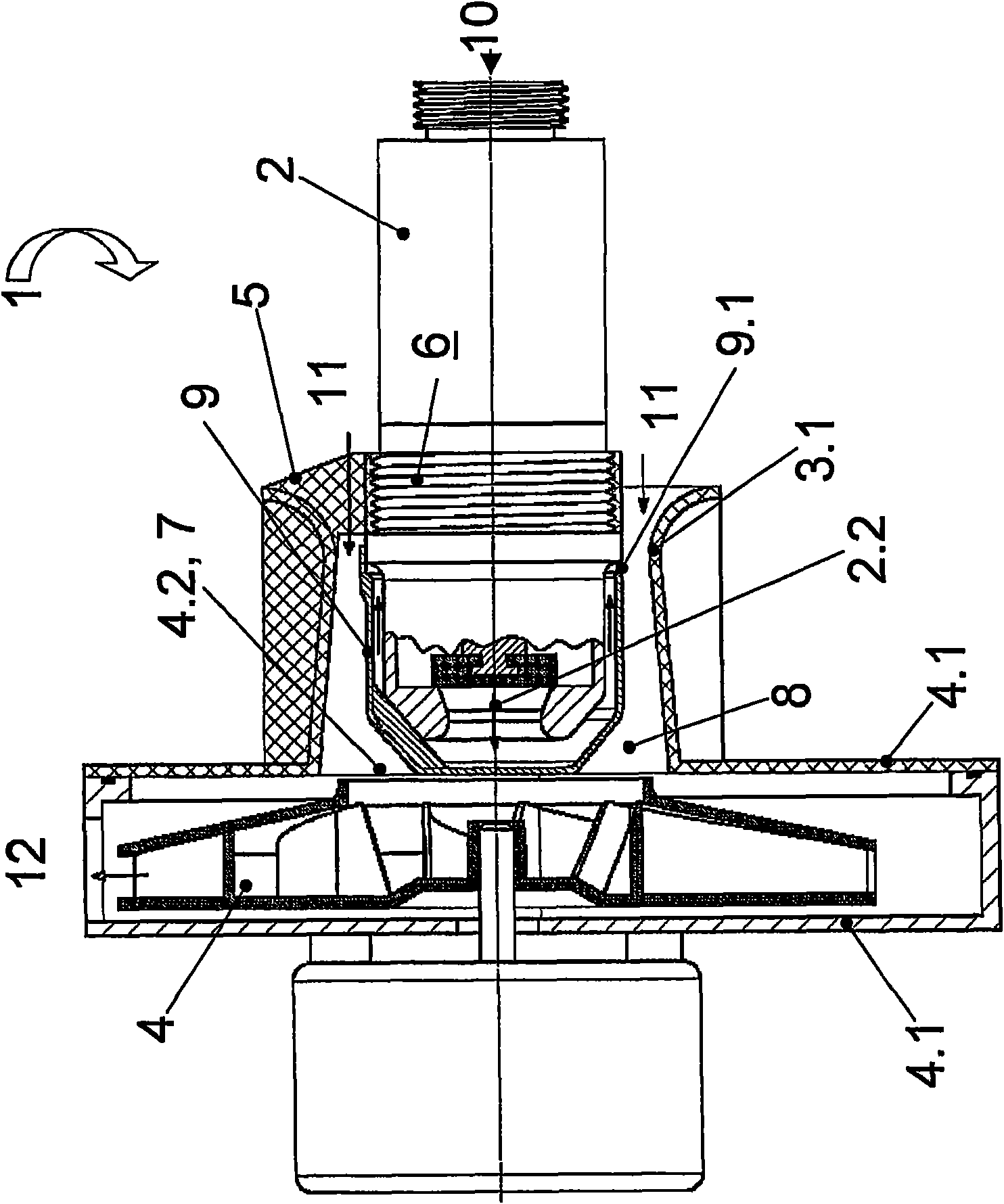

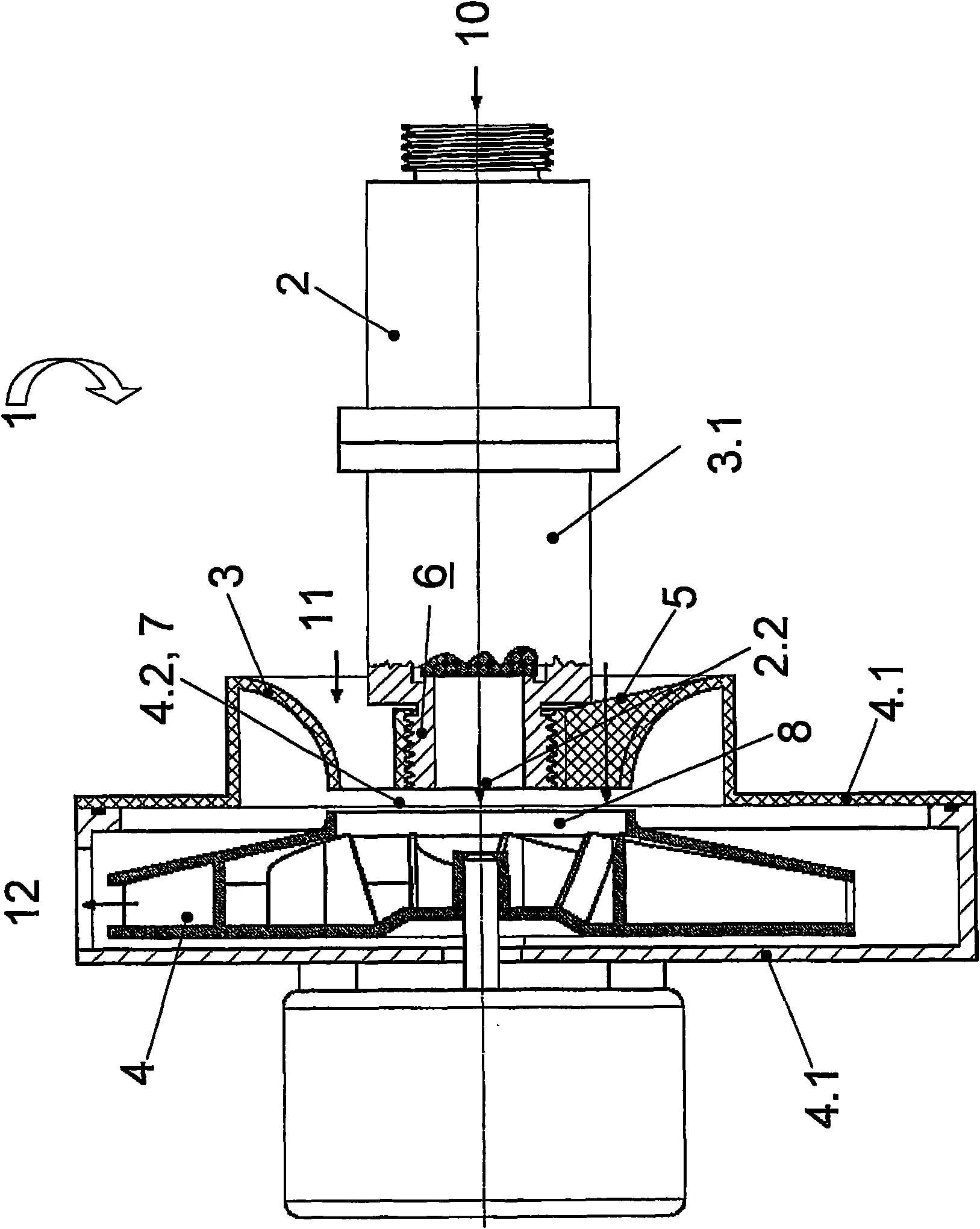

[0035] figure 1 A sectional view of a combined fan / air valve device 1 is illustrated with the suction side 4 . 2 of the fan housing 4 . 1 formed as a nozzle 3 and the fin 5 . The combined fan / air valve device 1 essentially comprises an air valve 2 with a housing 2.1, a nozzle 3 arranged behind the air valve 2 and an adjoining fan 4 formed as a radial fan with multipart ventilation Chassis 4.1. This embodiment of the invention is characterized in that the suction side 4.2 of the fan housing 4.1 is formed as a nozzle 3 to which the gas valve 2 is fixed by means of a fin 5 extending between the nozzle 3 and the housing 2.1 of the valve 2 3. The suction side 4.2 of the fan housing 4.1 is formed as a cover, which can fit into a complementary second housing 4.1 formed in the shape of a pot. The air valve 2 is arranged concentrically in the air inflow channel 7 of the fan 4 . While the gas 10 passes axially through the gas valve 2 , the air 11 is sucked in through the nozzle 3 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com