Group control system of elevators

A technology of control system and group management, applied in the direction of elevator energy efficiency, sustainable building, climate sustainability, etc., can solve problems such as difficulty in grasping power saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

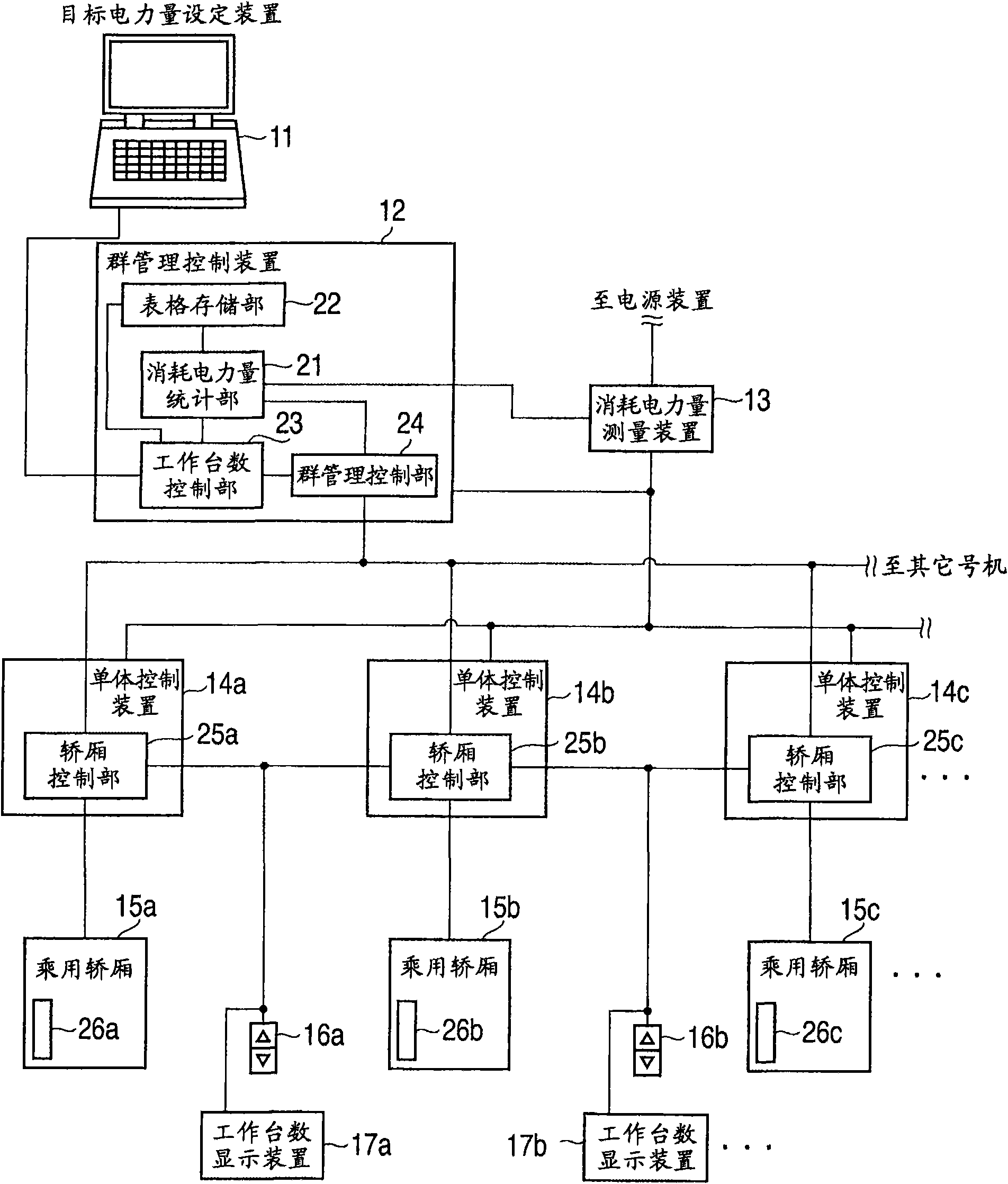

[0036] figure 1 It is a block diagram showing the configuration of the elevator group supervisory control system according to the first embodiment of the present invention.

[0037] The group management control system of the elevator in the present embodiment comprises: target power setting device 11, group management control device 12, power consumption measurement device 13, single control device 14a, 14b, 14c..., passenger car 15a , 15b, 15c..., call buttons 16a, 16b... at the elevator place, and display devices 17a, 17b... for the number of working tables.

[0038] The target power amount setting device 11 is installed in a building monitoring room or an elevator machine room, and is connected to a group supervisory control device 12 . The target power amount setting device 11 includes, for example, a personal computer, etc., and various target values (power consumption, power saving period) related to electrification can be arbitrarily set by a building manager (includ...

no. 2 Embodiment

[0093] Next, a second embodiment of the present invention will be described.

[0094] Its basic structure is the same as that of the above-mentioned first embodiment figure 1 same. In the second embodiment, the items that can be set by the target power amount setting device 11 are different.

[0095] that is, if Figure 8 As shown, in the setting item 51 provided on the setting screen 50, as the target value, in addition to the period during which power saving is implemented and the amount of use-permitted power allowed to be consumed during this period, the limit of the average waiting time can also be set arbitrarily. value and which of the limit value of the permitted power amount and the average waiting time should be prioritized for power saving.

[0096] In addition, in the display item 52 provided on the setting screen 50 , the current daily power consumption acquired from the power consumption statistics unit 21 via the number of operating machines control unit 23 a...

no. 3 Embodiment

[0109] Next, a third embodiment of the present invention will be described.

[0110] In the third embodiment, when there is a difference of more than a certain amount between the planned power consumption amount and the actual power consumption amount during the power saving implementation period, the number of operating machines is replanned and implemented during the remaining period.

[0111] Furthermore, the basic structure is the same as that of the first embodiment, as figure 1 structure shown in. In the third embodiment, when the actual power consumption during the power-saving implementation period is different from the plan, the number of workstations control unit 23 in the third embodiment may reconsider the planning of the number of workstations so as to satisfy the use-permitted power amount during the remaining power-saving implementation period. .

[0112] Here, use Figure 10 The processing flow when the planning of the number of tables is reconsidered in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com