Foamed rubber member

一种发泡橡胶、部件的技术,应用在发泡橡胶部件领域,能够解决传送力降低、图像不良等问题,达到耐久性优异、硬度低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

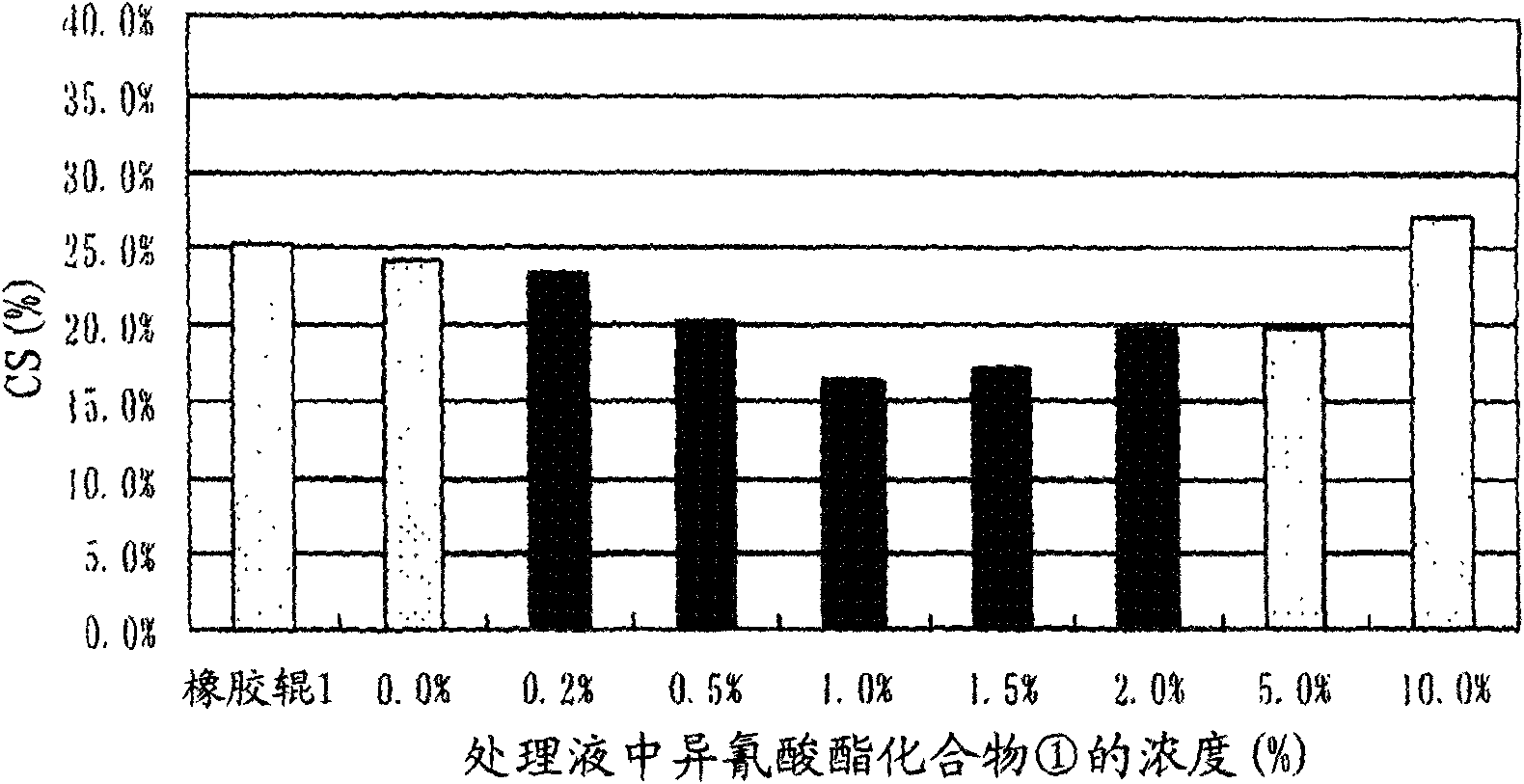

[0057] To 99.8 parts by mass of methyl ethyl ketone, 0.2 parts by mass of a terminal isocyanate compound (MR-400: manufactured by Nippon Polyuretan Co., Ltd., hereinafter referred to as isocyanate compound (1)) having a number average molecular weight of less than 500 was added and mixed to prepare a treatment liquid. The treatment solution was kept at 25° C., dipped for 30 seconds to allow the treatment solution to fully infiltrate the rubber roller 1, then dried naturally for 1 hour, and heated in an oven kept at 120° C. for 1 hour to obtain the rubber roller of Example 1. Foam rubber rollers.

Embodiment 2

[0059] The foam rubber roller of Example 2 was obtained like Example 1 except having used 99.5 mass parts of methyl ethyl ketone (MEK) and 0.5 mass parts of isocyanate compounds (1).

Embodiment 3

[0061] Except having used 99.0 parts by mass of methyl ethyl ketone and 1.0 parts by mass of isocyanate compound (1), it carried out similarly to Example 1, and obtained the foam rubber roller of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com