Accuracy correcting method of laser marking machine

A technology of laser marking machine and calibration method, which is applied in the direction of computer parts, digital marking record carriers, instruments, etc. It can solve the problems of high-precision special industries that cannot meet the requirements, the accuracy of software calibration methods, calibration errors, and low calibration accuracy, etc. problem, to achieve the effect of simple method, improved efficiency and high calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] The present invention adopts the method of combining software and hardware to correct the marking accuracy of the laser marking machine, and the specific implementation method is as follows:

Embodiment approach 1

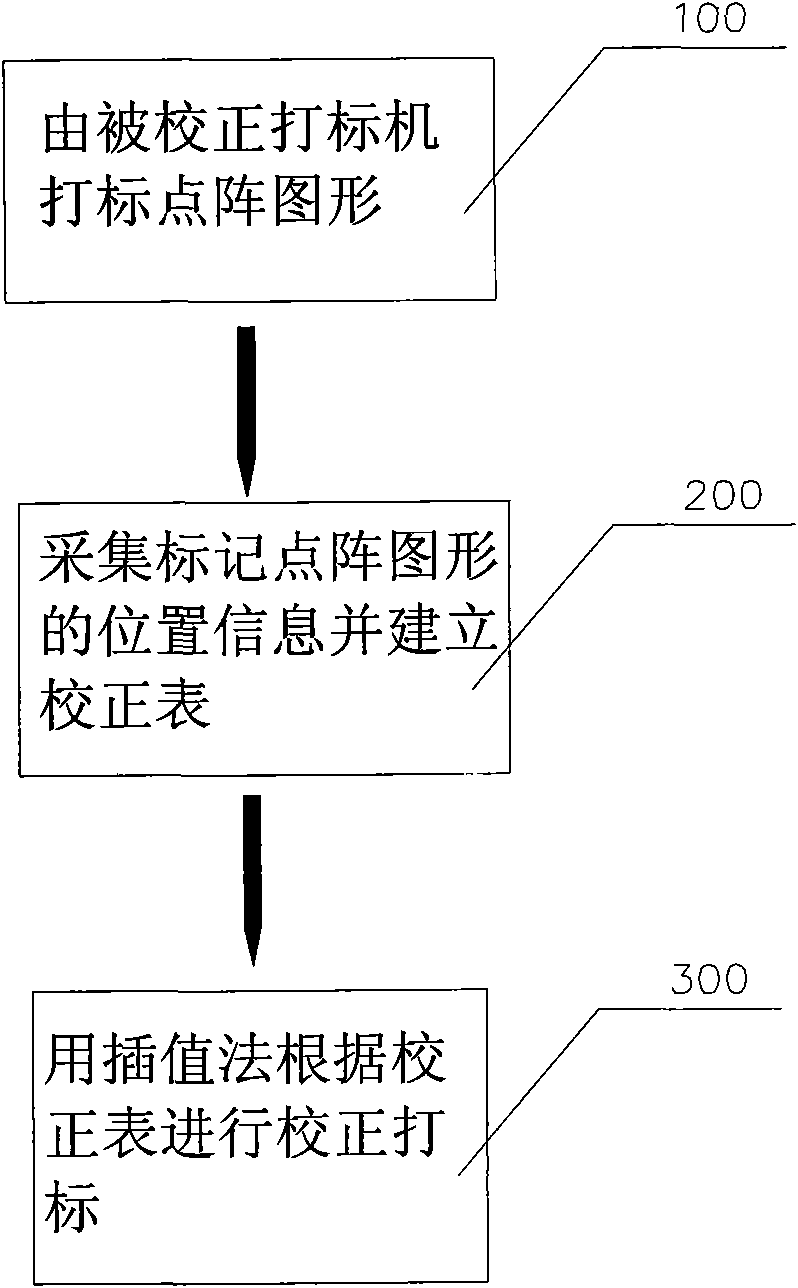

[0030] see figure 1 , is the flow chart of laser marking machine accuracy correction in the embodiment of the present invention, and the steps of the laser marking machine accuracy correction method in the present invention include:

[0031] Step 100: mark the dot matrix pattern by the corrected marking machine.

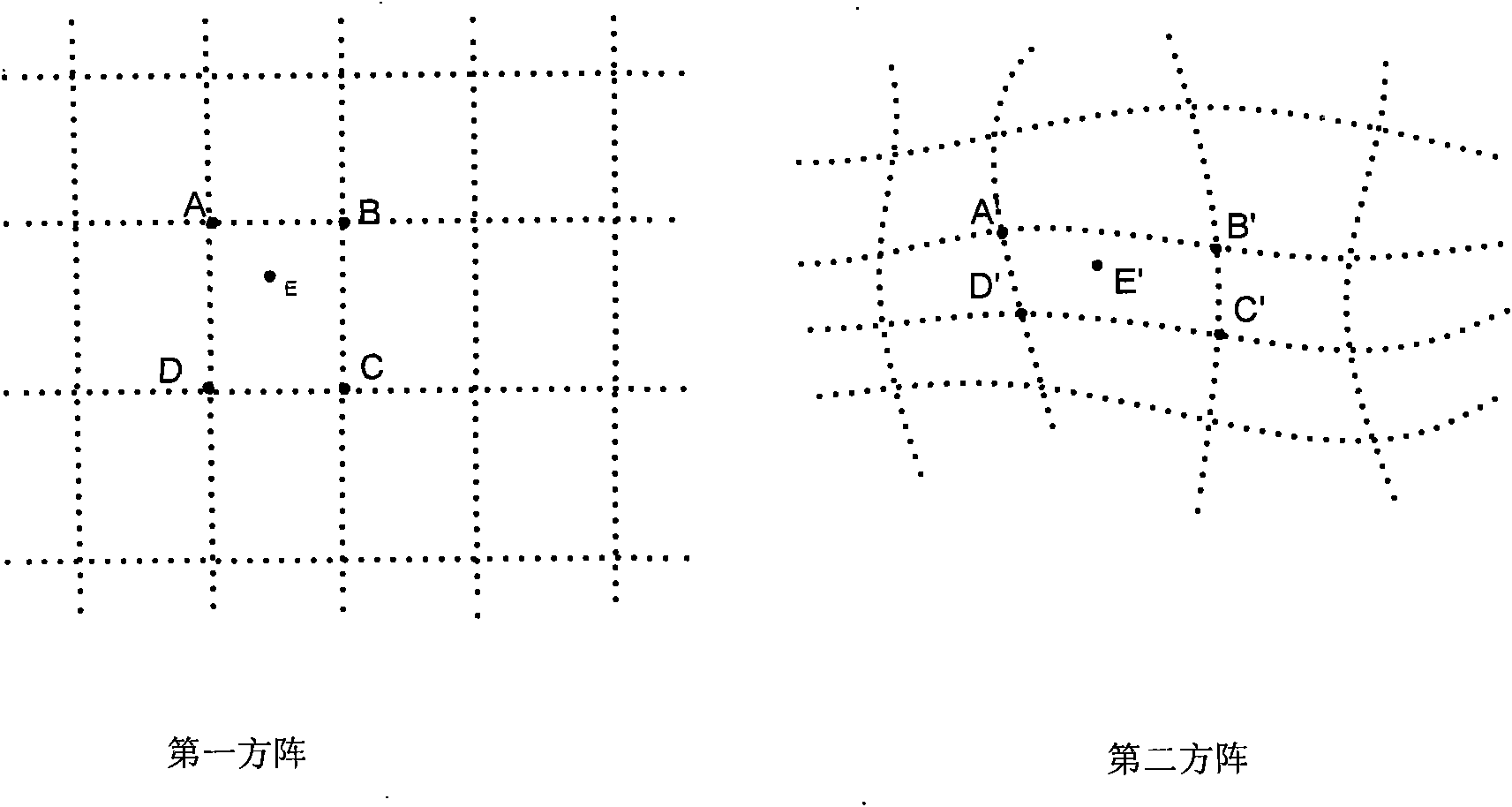

[0032] The marking system of the marking machine to be corrected issues a command to mark the dot matrix graphics, and the center point of the dot matrix graphics in the marking system command is taken to form a first square matrix, and the first square matrix is more than two rows and two columns square array.

[0033] Step 200: Collect the position information of the marked dot matrix pattern and establish a correction table.

[0034] The position information of the center point of the dot matrix graphic on the marker is collected to form a second square matrix, and the points of the second square matrix correspond to the points of the first square matrix respe...

Embodiment approach 2

[0054] In the first embodiment, the square matrix formed by the center points of the dot matrix pattern on the marker is directly collected, that is, the second square matrix. Due to the irregularity of the second square matrix, when judging whether a point falls within the range of which points in the second square matrix, the amount of calculation is large, the calculation process is long, and it is difficult to confirm quickly. Therefore, in order to simplify the calculation , adopt the following implementation method:

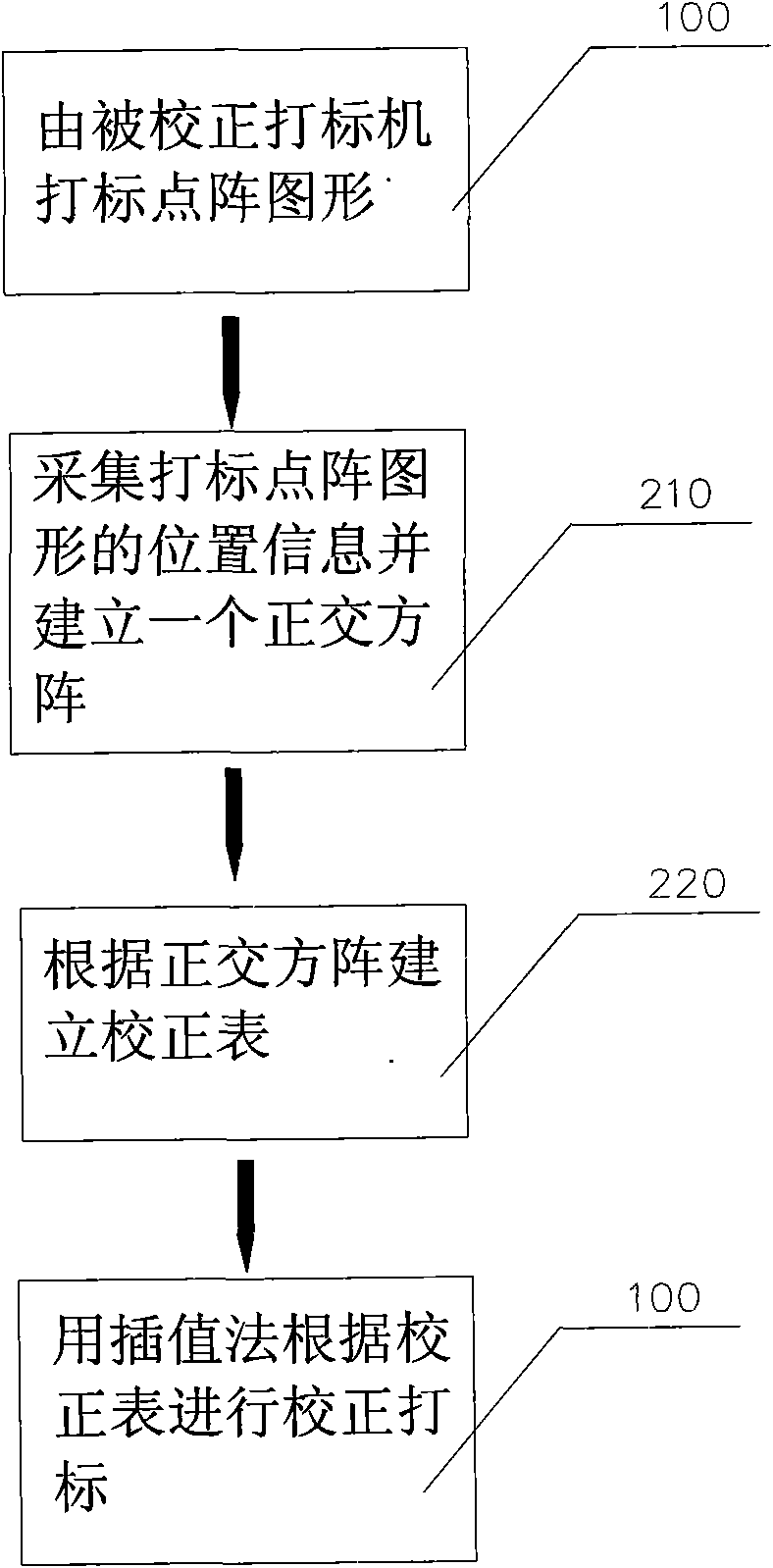

[0055] like image 3 As shown, it is a correction flowchart using an orthogonal square matrix. The implementation of this method includes the following steps:

[0056]Step 100: mark the dot matrix pattern by the corrected marking machine.

[0057] The marking system of the calibrated marking machine issues a command to mark the dot matrix graphics. The system commands the dot matrix graphics to be marked. The dot matrix graphics are a square matrix with m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com