Uniform inner heat source simulator of medical isotope production solution reactor

A technology for producing solutions and simulation devices, applied in the transformation of nuclear reactors, etc., can solve problems such as high simulation power, difficulty in realization, and deviation, and achieve reliability assurance, overcome high simulation power, and safety guarantees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

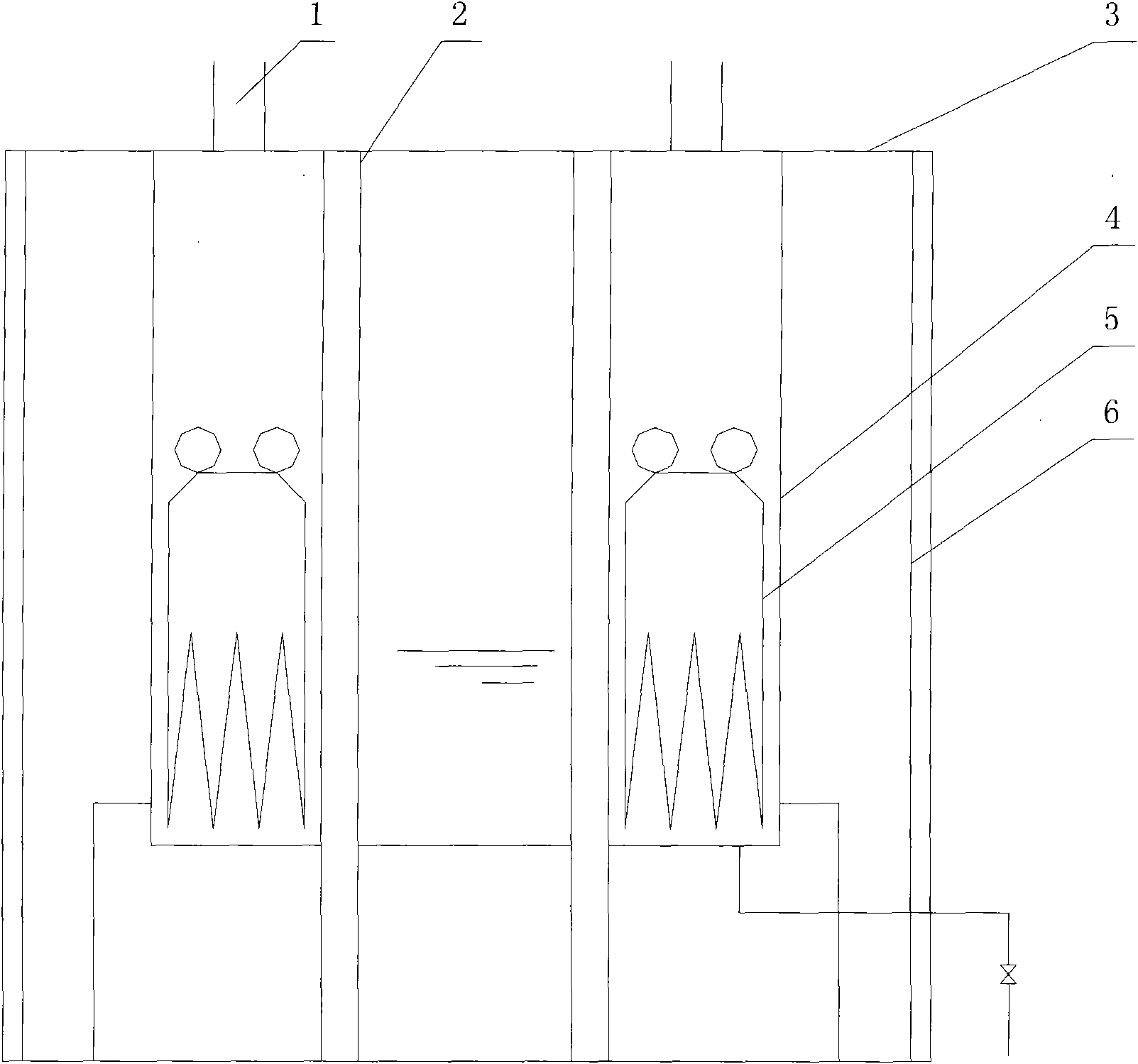

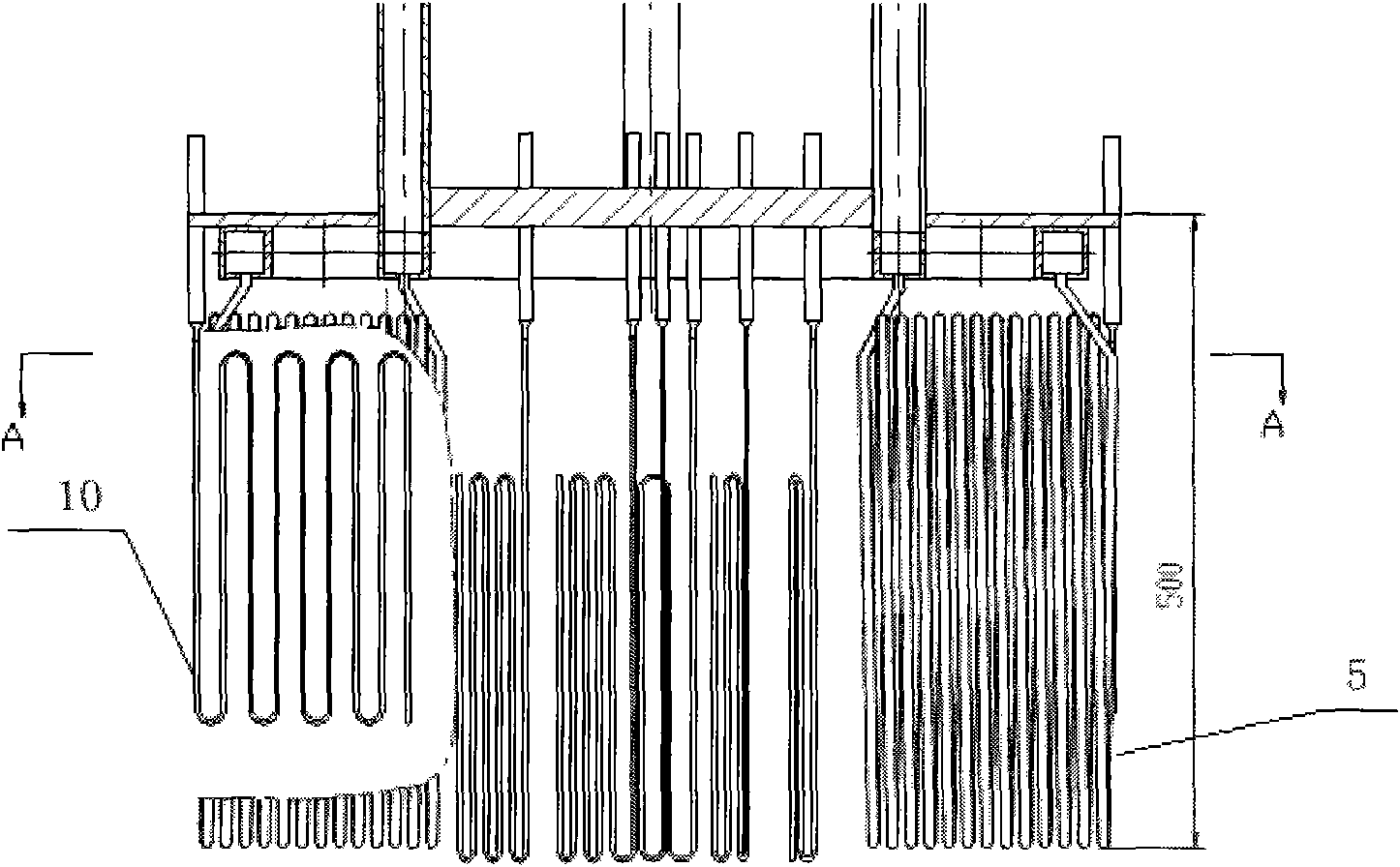

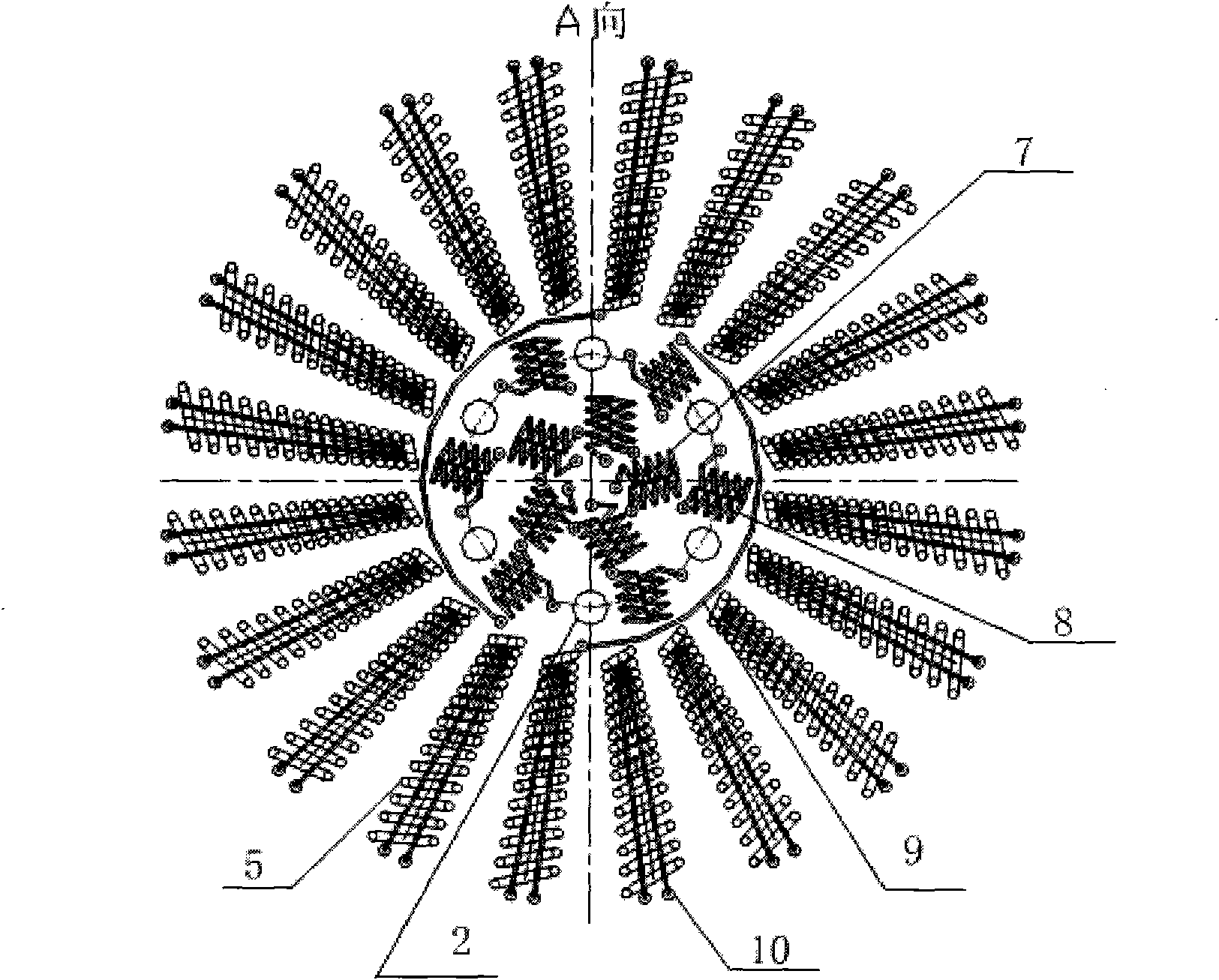

[0031] A specific embodiment of a uniform internal heat source simulation device for a medical isotope production solution stack of the present invention is introduced below in conjunction with the accompanying drawings:

[0032] Such as Figure 1-11 As shown, a medical isotope production solution pile uniform internal heat source simulation device, it includes a power simulation component composed of a heating component and a heat exchange component, and a fission gas simulation component; the heating component includes a zigzag a-shaped heating element 7 , a zigzag b-shaped heating element 8, an arc-shaped heating element 9, and a zigzag-shaped heating element 10, wherein five zigzag a-shaped elements 7 are evenly distributed on a φ100mm circumference, and six zigzag b-shaped elements 8 are evenly distributed on On the circumference of φ217.55mm, 2 arc-shaped elements 9 are evenly distributed on the circumference of φ284mm, and 20 broken-line elements 10 are evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com