Glass plate packing body

A glass plate and packaging technology, applied in packaging, transportation and packaging, packaging of fragile items, etc., can solve the problems of uneven stacking state, damage, and improper pressing force of glass plate stacks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be described below with reference to the drawings.

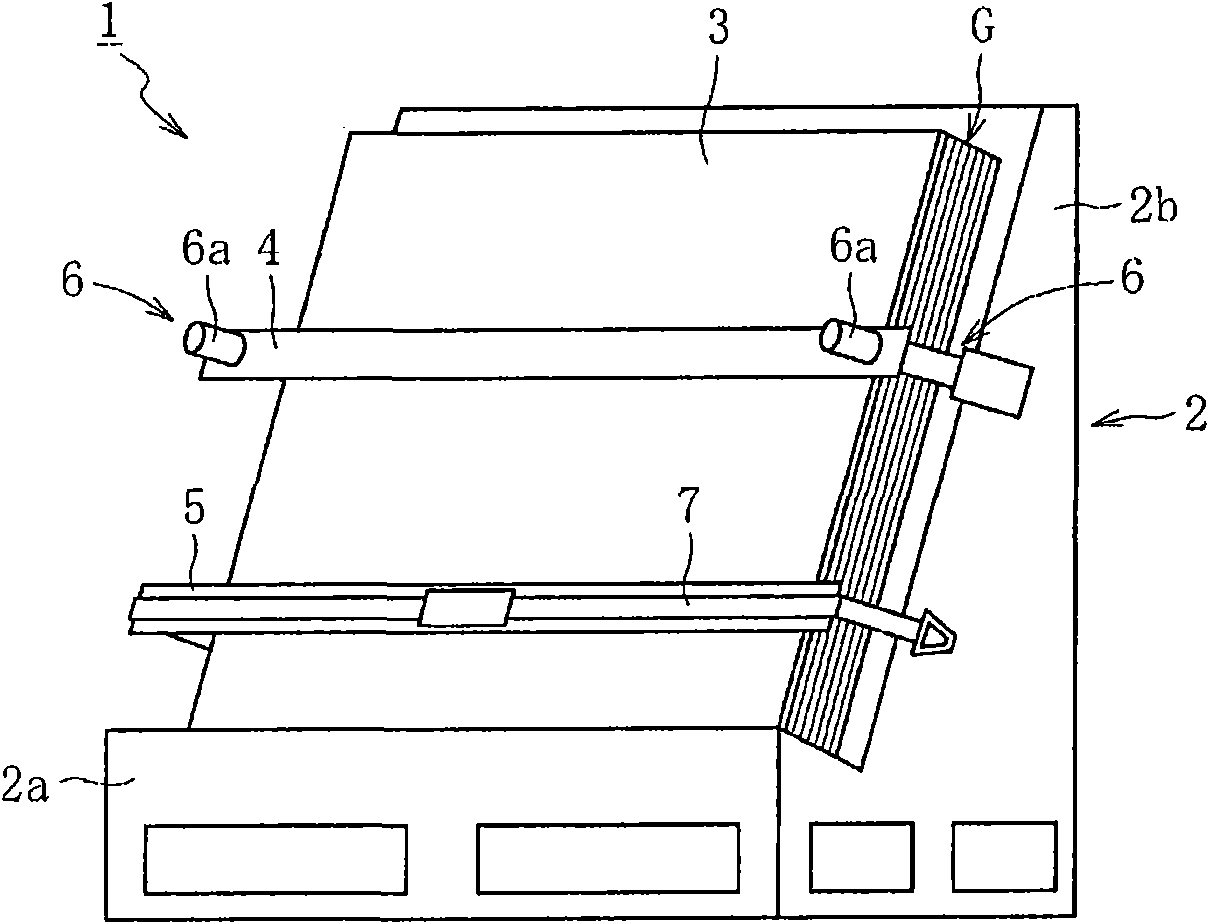

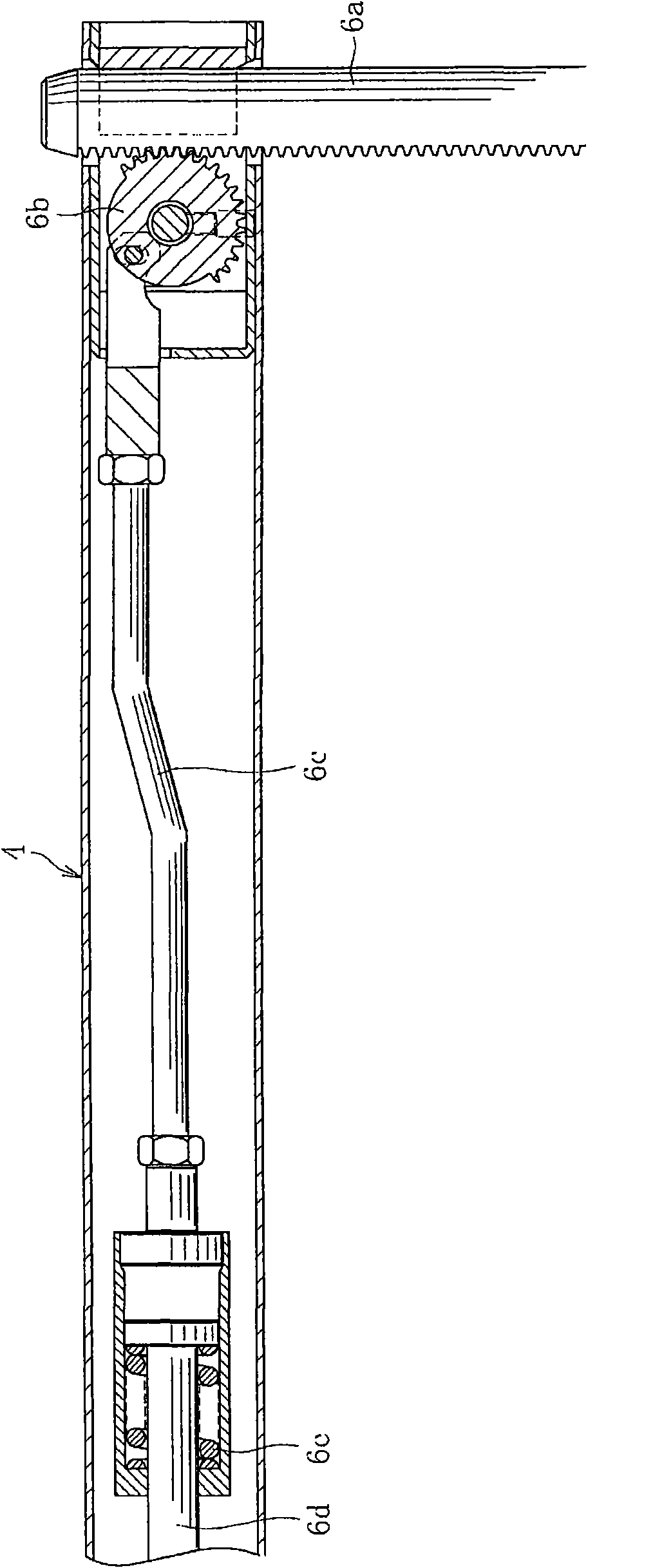

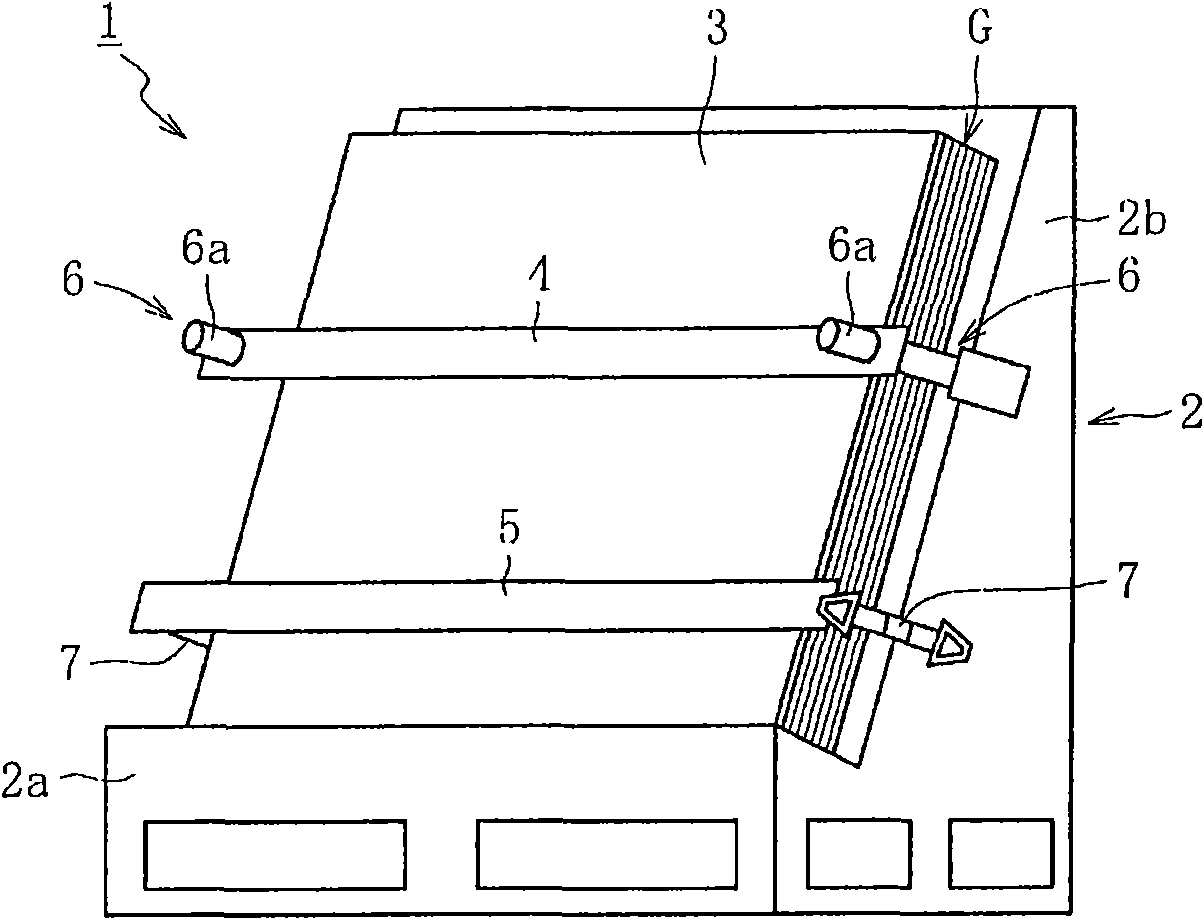

[0047] figure 1 It is a perspective view which schematically shows the glass plate package of 1st Embodiment of this invention. This glass plate package 1 is a member that laminates a plurality of glass plates in a vertical posture (inclined posture in the example of illustration) on a tray 2 and holds the glass plate laminated body G on the tray 2 .

[0048] The tray 2 has a base part 2a which supports the bottom part of a glass plate, and the back receiving part 2b which stands behind the base part 2a and supports the back surface of a glass plate. Then, by placing the lower edge portions of the plurality of glass plates on the base portion 2a and leaning the back portion of the last glass plate against the back receiving portion 2b, the plurality of glass plates are stacked on the tray 2 in a vertical posture. . This glass plate laminated body G is comprised by sandwichi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com