Antistatic tool

An anti-static and appliance technology, applied in the direction of static electricity, application, circuit, etc., can solve problems such as the inability to fully solve the pressure marks, achieve reliable anti-static performance, improve yield and workability, and prevent explosions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

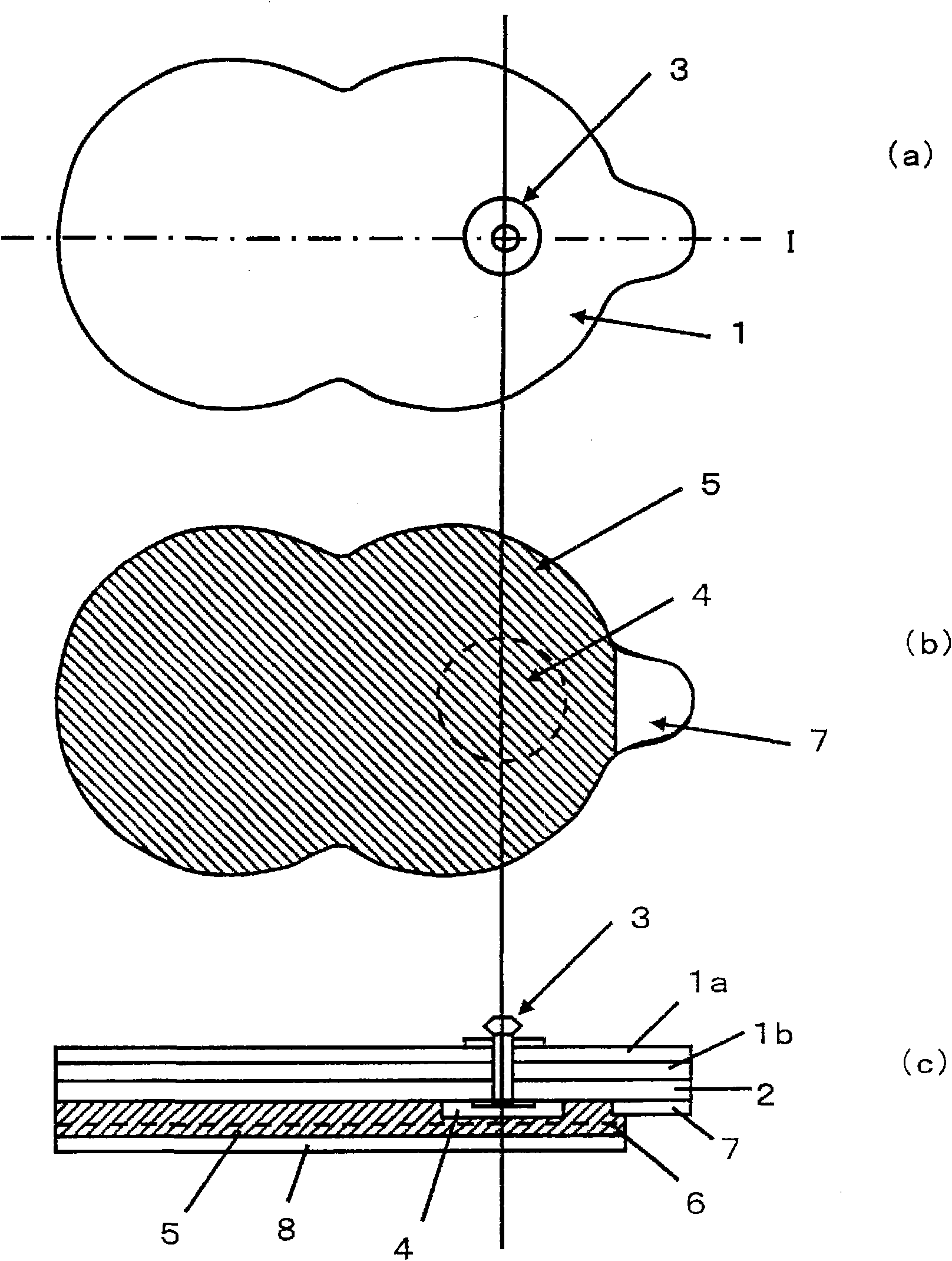

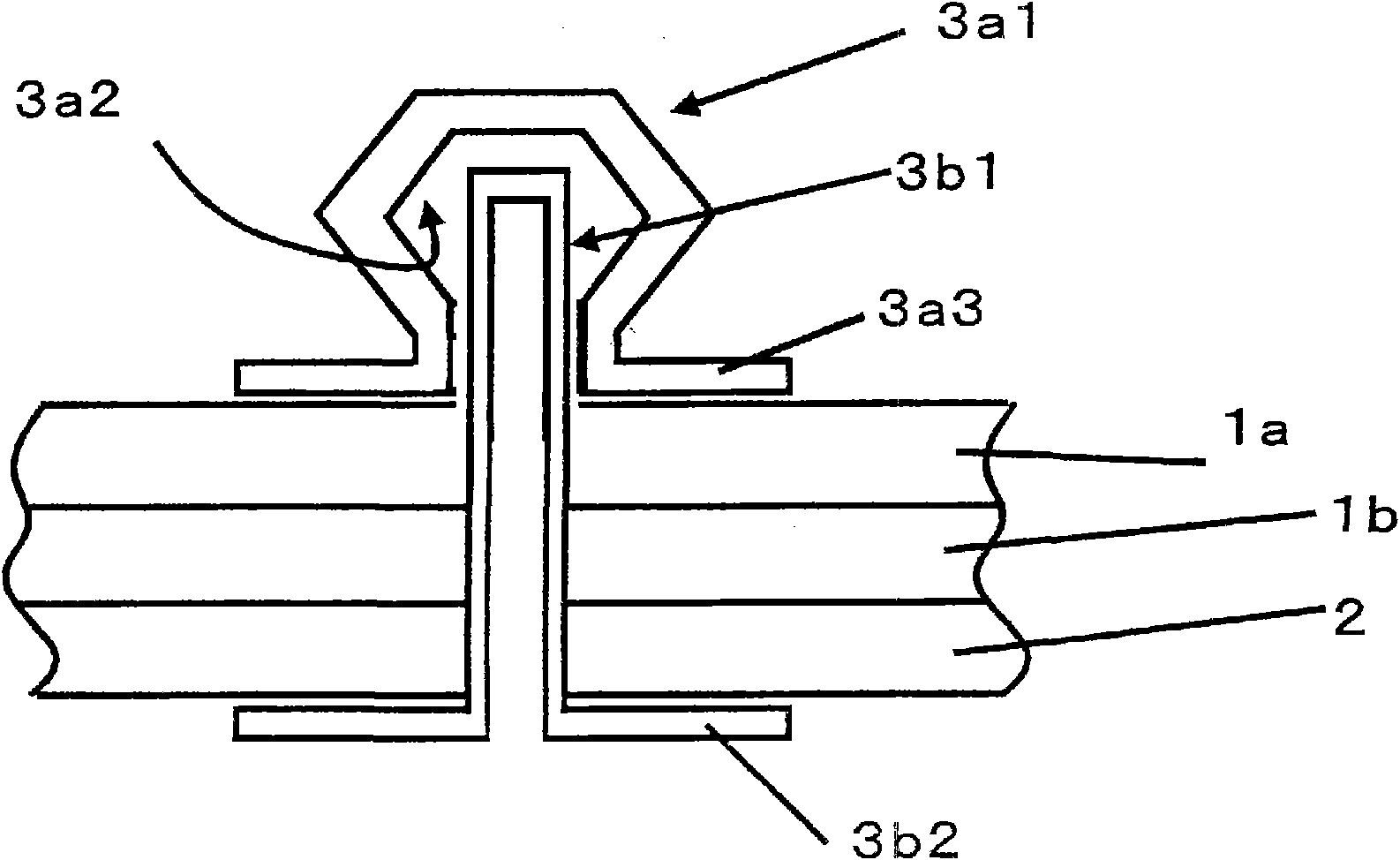

[0105] figure 1 (a)~(c) and figure 2 A schematic diagram of the antistatic appliance of Example 1 is shown in . figure 1 (a) is the top view schematic diagram of the antistatic appliance of embodiment 1, figure 1 (b) is the rear view schematic diagram of the antistatic appliance of embodiment 1, figure 1 (c) is the schematic sectional view of the I-I line of the antistatic appliance of embodiment 1, figure 2 yes figure 1 (c) An enlarged schematic view of the terminal portion. In addition, in figure 1 (a)~(c) and figure 2 Among them, reference numeral 1 is a supporting member, 1a is a soft polyethylene layer, 1b is a polyester film, 2 is a conductive layer, 3 is a terminal part, 3a is a conductive snap button, 3b is a conductive part, 4 is a cover layer, 5 is the conductive adhesive layer, 6 is the intermediate substrate, 7 is the non-adhesive layer, 8 is the protective film, 3a1 is the convex part of the conductive snap, 3a2 is the concave part of the conductive snap...

Embodiment 2

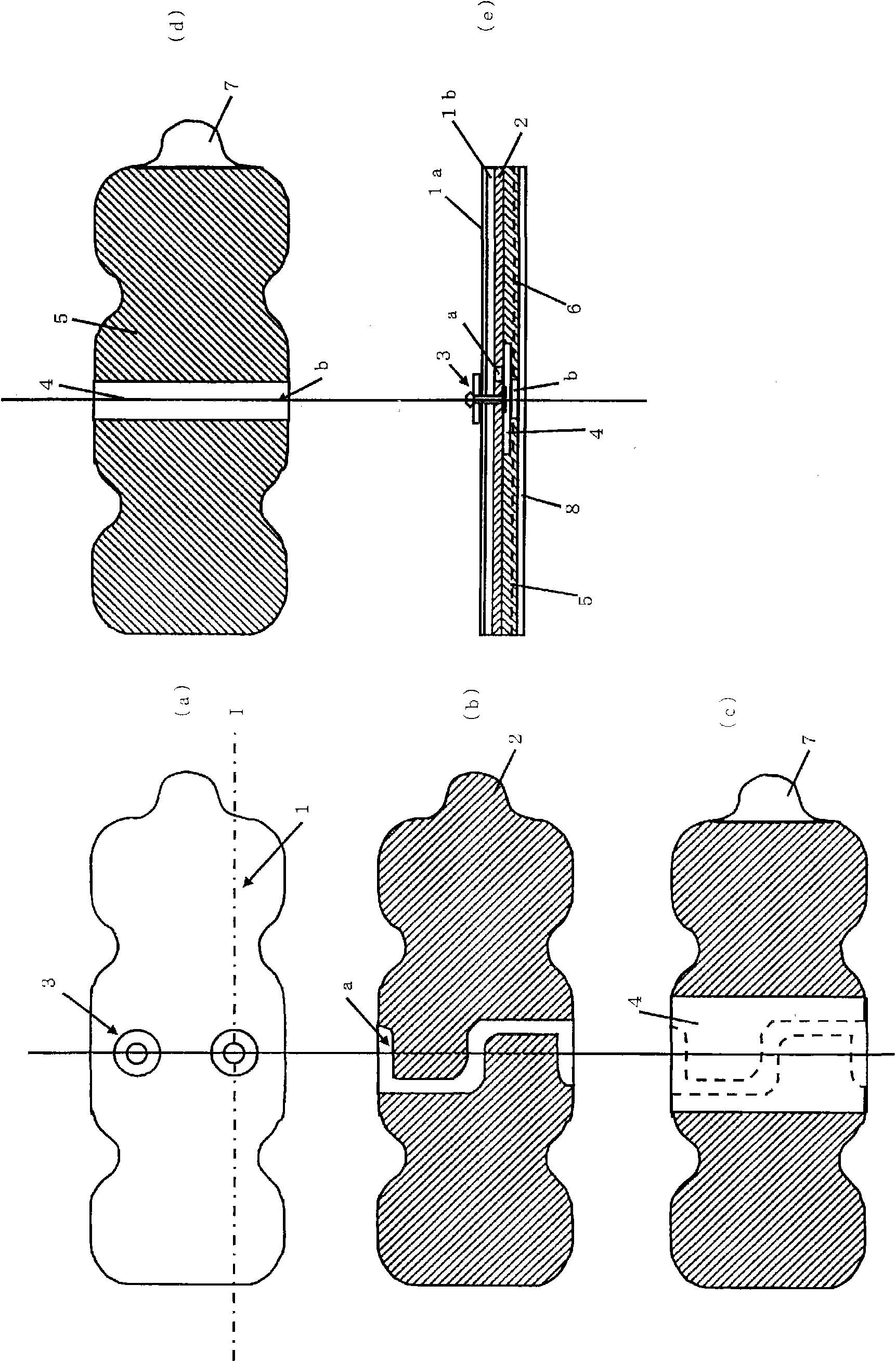

[0130] image 3 (a)-(e) shows the schematic diagram of the 2-terminal type antistatic tool of Example 2. image 3 (a) is the top view schematic diagram of the antistatic appliance of embodiment 2, image 3 (b) is a figure which shows the arrangement|positioning of the electroconductive layer of the antistatic tool of Example 1. image 3 The hatched portion in (b) is a conductive layer, and there is an S-shaped portion a where no conductive layer is formed near the center. image 3 (c) The figure which shows the state which laminated|stacked the covering layer and the non-adhesive layer. image 3 (d) The figure which shows the state which laminated|stacked the electroconductive adhesive layer. image 3 In (d), there exists a part b in which the electroconductive adhesive layer is not formed. image 3(e) is a schematic cross-sectional view of the I-I line of the antistatic appliance in embodiment 2. The terminal part of the antistatic appliance of embodiment 2 has figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com