Anti-seismic strengthening device of prefabricated hollow floorslab brick mixed structure building floor

A technology of brick-concrete structure and hollow floor slab is applied in the direction of earthquake resistance, building components, building structure, etc. to achieve the effect of extending the length of the bearing, improving the seismic performance, and meeting the needs of aesthetics.

Active Publication Date: 2011-01-05

THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the problem of anti-seismic reinforcement of existing prefabricated hollow slab brick-concrete structure houses, the present invention provides a prefabricated hollow slab brick-concrete structure building floor anti-seismic reinforcement device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

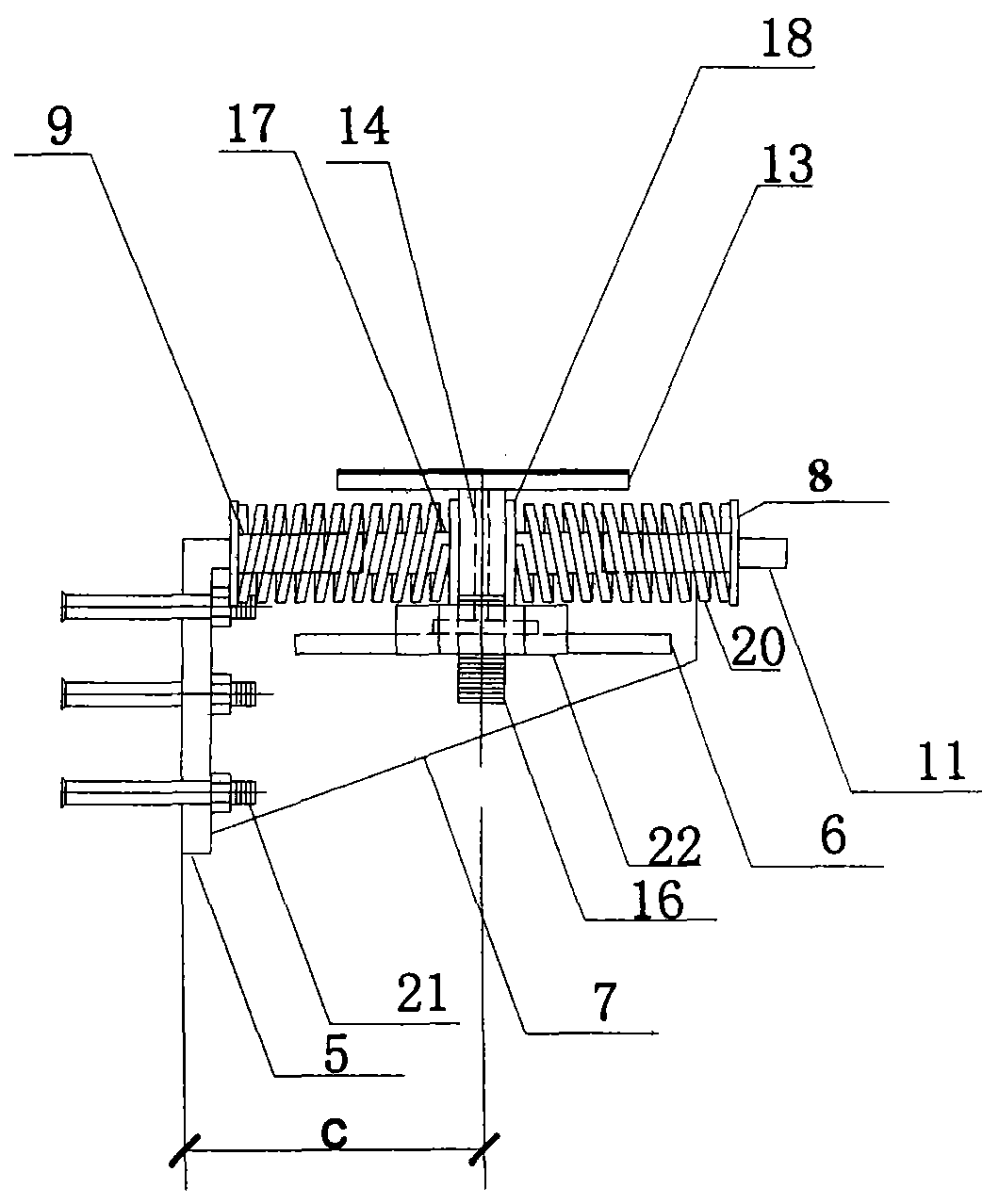

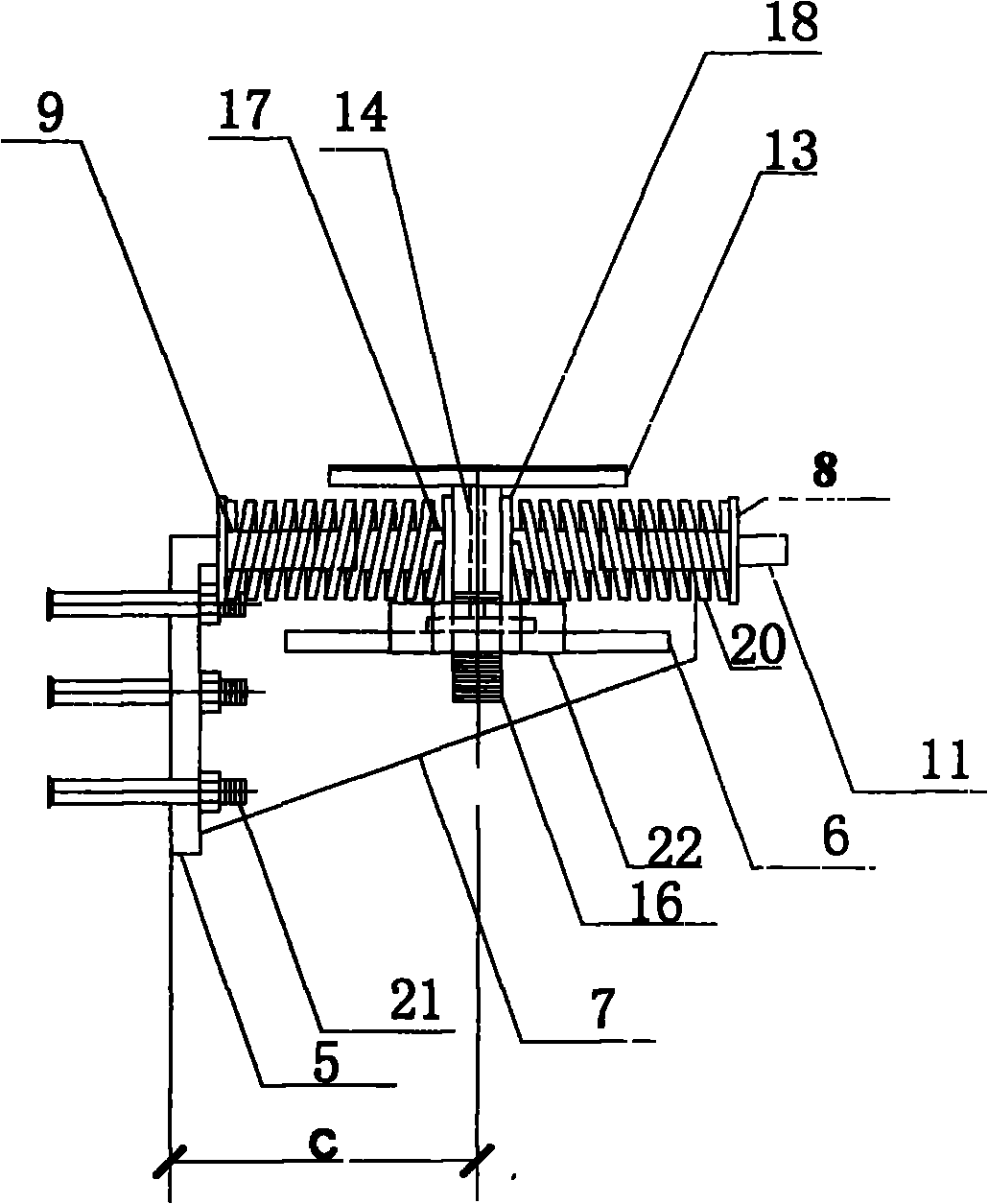

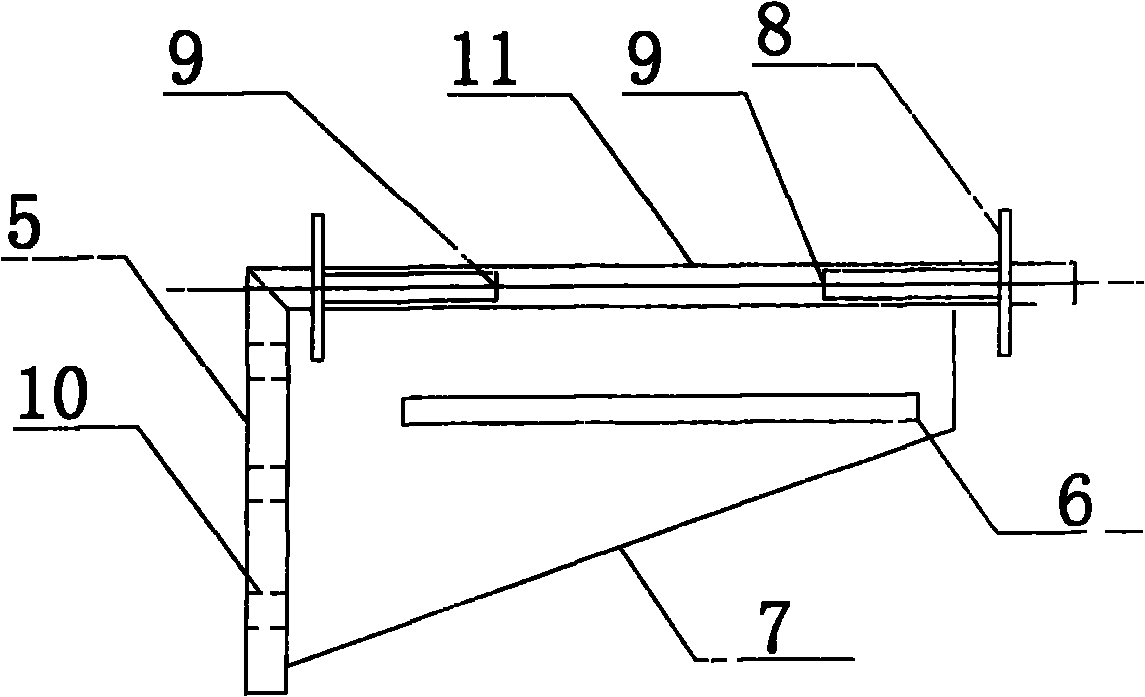

The invention relates to an anti-seismic strengthening device of a prefabricated hollow floorslab brick mixed structure building floor, comprising a bearing steel frame and an I-shaped steel band, wherein the bearing steel frame is a right-angle frame on which a catch spring plate and a catch spring shaft are arranged; the I-shaped steel band comprises a top flange plate, a web plate and a lower flange plate, wherein an installation slot is installed in the position in which an interval of 1200-1360 mm is formed between the lower flange plate and the web plate, and bolts, a catch spring sheetand a spring shaft sleeve are arranged in the installation slot. The invention has the following construction installation steps: installing the bearing steel frame on the side surface of a building ring beam in every 1.2 m by expansion bolts; splicing the top flange plate of the I-shaped steel band by engineering structural glue below the prefabricated hollow floorslab and above the bearing steel frame; putting the lower flange plate of the I-shaped steel band on the bearing plate of the bearing steel frame; and fixing the top flange plate between high-strength springs of the bearing steel frame by bolts. The hollow floorslab is elastically connected with the bearing steel frame by the I-shaped steel band and consumes seismic energy during the earthquake, preventing the hollow floorslab from falling off, preventing buildings from collapsing and ensuring safety of life and property of personnel.

Description

Prefabricated Hollow Slab Brick Concrete Structure Floor Seismic Strengthening Device technical field The invention relates to an anti-seismic reinforcement device for a prefabricated hollow floor brick-concrete structure building floor. Background technique Looking at the strong earthquakes in the world since the 20th century, the Alaska earthquake in the United States (March 28, 1964) was 8.8 on the Richter scale and 125 people died; on January 17, 1995 in Japan, a 7.3-magnitude earthquake occurred in the Hanshin area, killing 6434 people. ..... Among the previous earthquakes, my country suffered the most severe losses. More than 300,000 people were killed in the Tangshan earthquake and this Wenchuan earthquake. Beginning in 1996 after the Hanshin earthquake, Japan revised the "Building Standards Law" three times to raise the seismic standards of all types of buildings to the highest level, especially requiring the seismic capacity of commercial buildings to reach level ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04B1/98E04G23/02

Inventor 李明焦宁艳杨立胜张庆远

Owner THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com