Water level observation well and construction method thereof

A technology for water level observation wells and construction methods, which is applied in basic structure engineering, on-site foundation soil surveying, construction, etc., can solve problems such as easy leakage and distortion of observation results, and achieve a structure that is not easy to break, low in cost, and accurate in observation results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

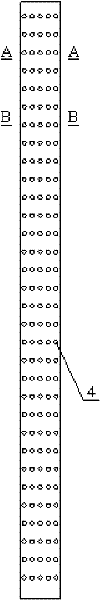

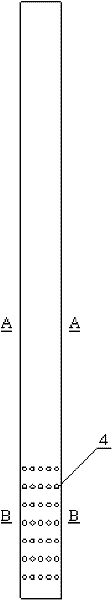

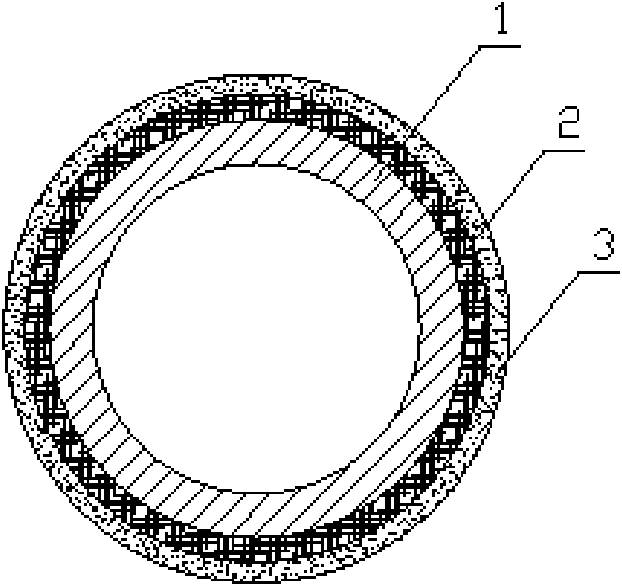

[0032] The excavation area of a high-rise residential building foundation pit project is 12,300 m 2 , and the depth of the foundation pit is 15.130m. The surrounding of the foundation pit adopts an underground diaphragm wall, the depth of which is 34 meters, and the thickness of the wall is 1.0 meters. The water level observation well of the submerged layer is arranged around the foundation pit, and the structure of the water level observation well is as follows: figure 1 , image 3 with Figure 4 shown.

[0033] The top-to-bottom vertical distribution of strata within the excavation depth range of the foundation pit is:

[0034] ①Artificial fill and miscellaneous fill, thickness 2.3m ;

[0035] ② Silty clay, thickness 5.1m;

[0036] ③ Silt, thickness 11.4m ;

[0037] ④ Silty clay, thickness 5.7m ;

[0038] ⑤silt, thickness 9.80m ;

[0039] ⑥silt, thickness 8.10m ;

[0040] ⑦silty clay, thickness 14.5m ;

[0041] ⑧silt, thickness 16.30m .

[0042] The abov...

Embodiment 2

[0046] The excavation project of a subway tunnel is 260m long, 20.5m wide, and the excavation depth is 15.420m. An underground continuous wall is adopted around the foundation pit, the ground connection wall is 35 meters deep and the wall thickness is 1.2 meters. Water level observation wells for aquifers and confined aquifers are arranged around the foundation pit, see Figure 1 ~ Figure 4 .

[0047] The top-to-bottom vertical distribution of strata within the excavation depth range of the foundation pit is:

[0048] ①Artificial fill and miscellaneous fill, thickness 3.4m ;

[0049]② Silt, thickness 12.1m ;

[0050] ③ Silty clay, thickness 3.6m;

[0051] ④ Silt, thickness 2.5m;

[0052] ⑤silt, thickness 10.0m ;

[0053] ⑥silty clay, thickness 12.5m ;

[0054] ⑦silt, thickness 10.3m ;

[0055] ⑧silt, thickness 5.4m .

[0056] The water level observation well in the aquifer uses PVC pipes. The nominal outer diameter of the PVC pipe section is 90mm, the thickness ...

Embodiment 3

[0062] The foundation pit project of a subway station is 463m long, 19.35m wide, and 18.590m deep. An underground continuous wall is adopted around the foundation pit, the depth of the ground connection wall is 38 meters, and the wall thickness is 1.2 meters. Water level observation wells for aquifers and confined aquifers are arranged around the foundation pit, see Figure 1 ~ Figure 4 .

[0063] The top-to-bottom vertical distribution of strata within the excavation depth range of the foundation pit is:

[0064] ①Artificial fill and miscellaneous fill, thickness 4.50m;

[0065] ② Silt, thickness 13.00m;

[0066] ③ Silty clay, thickness 4.0m;

[0067] ④ Silt, thickness 2.80m;

[0068] ⑤silt, thickness 13.10m;

[0069] ⑥Silly clay with a thickness of 21.5m.

[0070] The water level observation well in the aquifer uses PVC pipes. The nominal outer diameter of the PVC pipe section is 200mm, the thickness is 3.9mm, the total pipe length is 10m, the first pipe section is 6m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com