Spine clamp-spring connected clutch release bearing

A technology for separating bearings and clutches, applied in clutches, mechanical drive clutches, ball bearings, etc., can solve problems such as low production efficiency, unreliable connection, and increased labor intensity, and achieve improved production efficiency, reliable connection, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

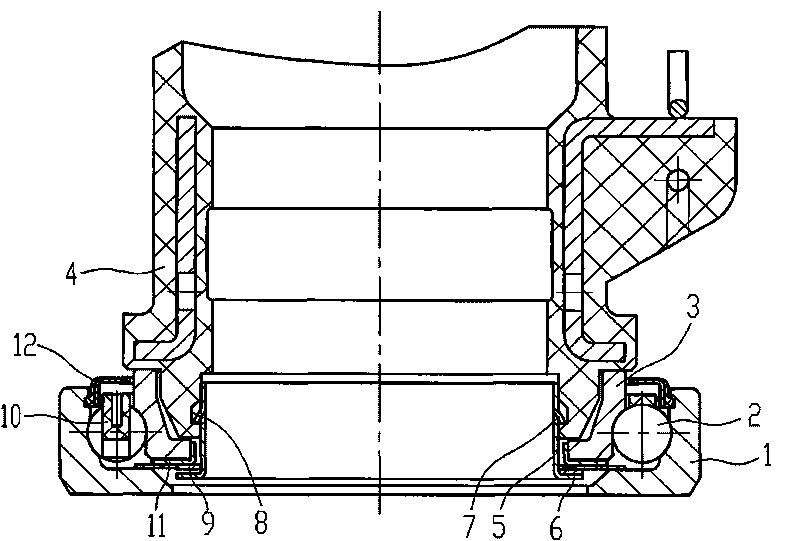

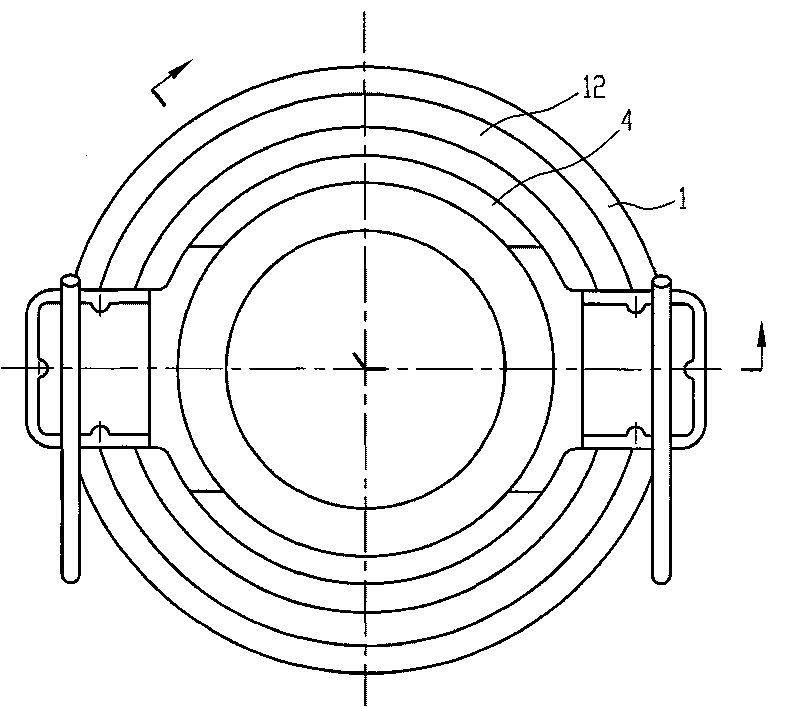

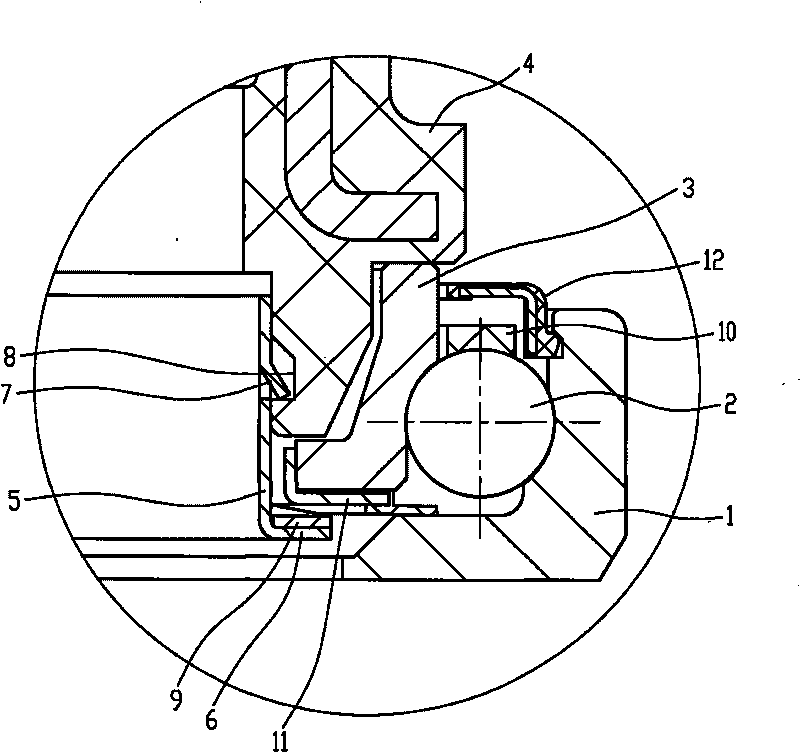

[0010] Such as figure 1 , 2 As shown in and 3, the ratchet-shaped circlip connection type clutch release bearing of this embodiment includes an outer ring 1, a roller 2, an inner ring 3, a bearing seat 4 and a ratchet-shaped circlip 5, and the ratchet-shaped circlip 5 is provided at the lower end. There is a circular body with an outer flanging 6, and the outer wall of the thorn-shaped circlip 5 is evenly distributed with thorns 7 facing downward. The ring 3 is set on the outside of the lower port of the bearing seat 4, and the ratchet-shaped circlip 5 is fixed on the inner side of the lower port of the bearing seat 4 through the thorn body 7. There is an annular pressing ring between the lower end surface of the inner ring 3 and the outer flange 6 of the ratchet-shaped circlip 5. Spring 9, the lower end surface of inner ring 3 is limited by the outward flange 6 of stage clip 9 and ratchet jumper 5.

[0011] A cage 10 is provided between the outer ring 1 and the inner ring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com