Ultra-long optical fiber unit and its manufacturing method

A technology of optical fiber unit and manufacturing method, applied in the direction of fiber mechanical structure, etc., can solve the problems of complex construction, unstable signal, slow speed, etc., and achieve the effects of reducing mechanical and high temperature damage, good lubrication and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

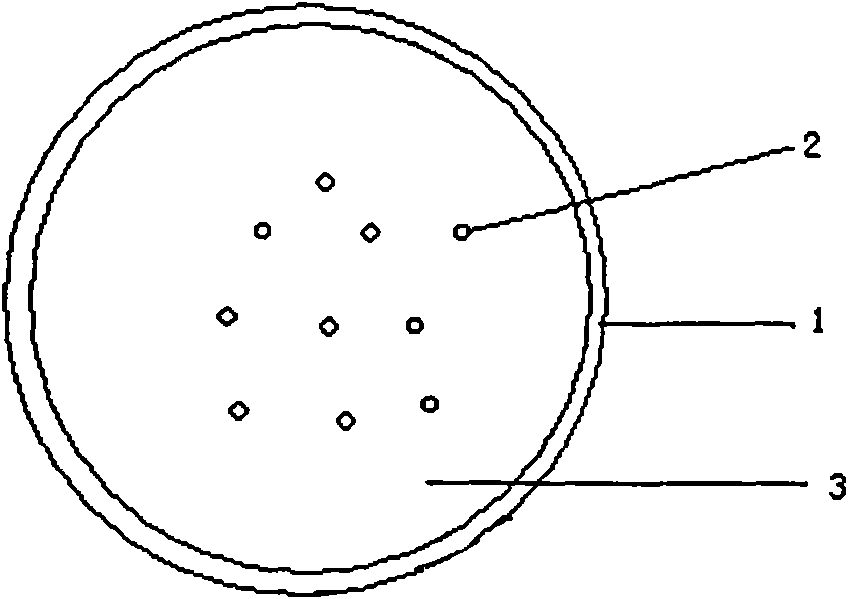

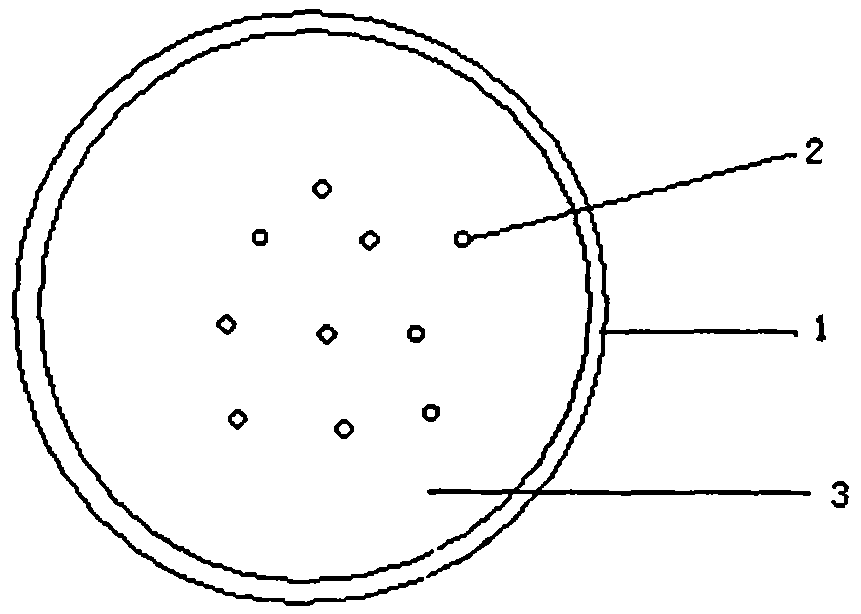

[0020] Reference attached figure 1 , The ultra-long optical fiber unit includes stainless steel tube 1, full-chromatographic submarine cable dedicated optical fiber 2 and high-viscosity hydrogen evolution fiber paste 3; stainless steel ribbon (304L), formed and welded into a stainless steel tube 1, imported full-chromatographic submarine cable dedicated optical fiber 2, full Fill high viscosity hydrogen evolution fiber paste 3. The outer diameter of the optical fiber unit is 2.5-4.5mm, the fiber core of the optical fiber unit is 2-144 dedicated optical fibers for submarine cables 2, and the length of the optical fiber unit is 50-120km. The stainless steel belt is a commercially available 304L stainless steel belt.

[0021] The manufacturing method of the ultra-long fiber unit is as follows:

[0022] 1. According to the length of the optical fiber unit, the optical fiber is manufactured according to the ratio of 1:1.05-1.1, and then after a large tension screening of 100-150g, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com