Rotating disc type multi-nozzle three-dimensional controlled forming system for complex organ precursor

A multi-nozzle, turntable technology, applied in prosthetics, medical science, brackets, etc., can solve problems such as no specific instructions for multi-nozzle structure design, failure to meet the forming requirements of large-size brackets, and inconvenient switching of nozzle components, etc., to achieve Reduced power, high degree of structural automation, simple and reliable device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

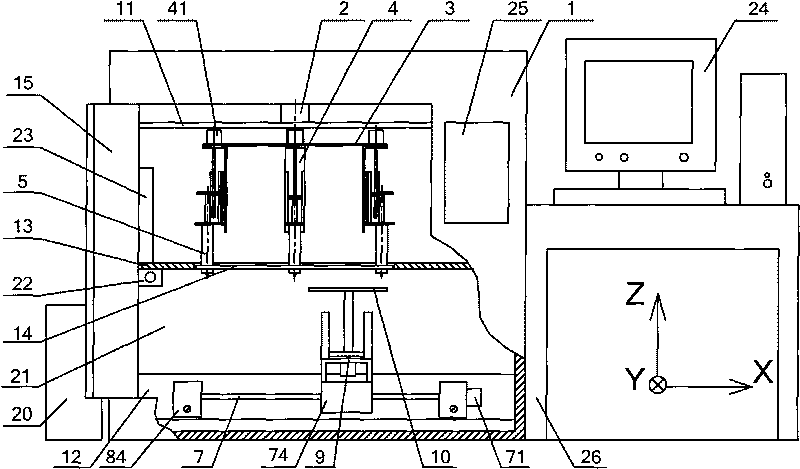

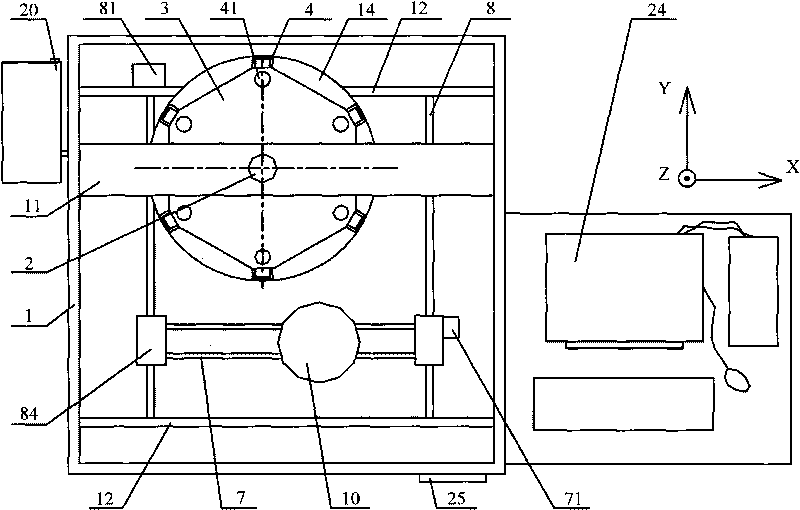

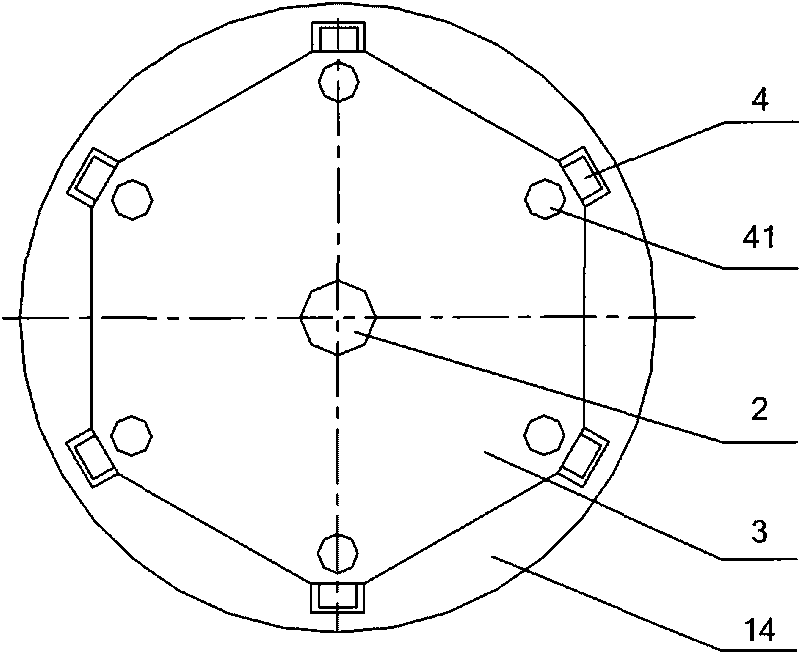

[0058] The specific structure, working principle and working process content of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0059] The embodiment of the three-dimensional controlled forming system of the rotary disk type multi-nozzle complex organ precursor designed by the present invention, such as Figure 1 ~ Figure 3 As shown, the system includes a box body 1, a bracket, a spraying device, a forming chamber 21, a three-dimensional motion mechanism, a forming table 10, a refrigeration device 20, and a control and data processing system. The spraying device is a rotary disc multi-nozzle spraying device , the turntable multi-nozzle spraying device includes a turntable 3 and at least one spray head assembly 4, the spray head assembly 4 is evenly distributed on the turntable 3 in the circumferential direction, and is fixed with the turntable 3, and the turntable rotates with the spray head assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com