Packaging method and equipment of wood chip splinters

A packaging equipment and packaging method technology, applied in packaging, multiple packages, transportation and packaging, etc., can solve the problems of affecting workers' health, low efficiency of manual bagging, and high labor costs, so as to reduce packaging costs and improve efficiency. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

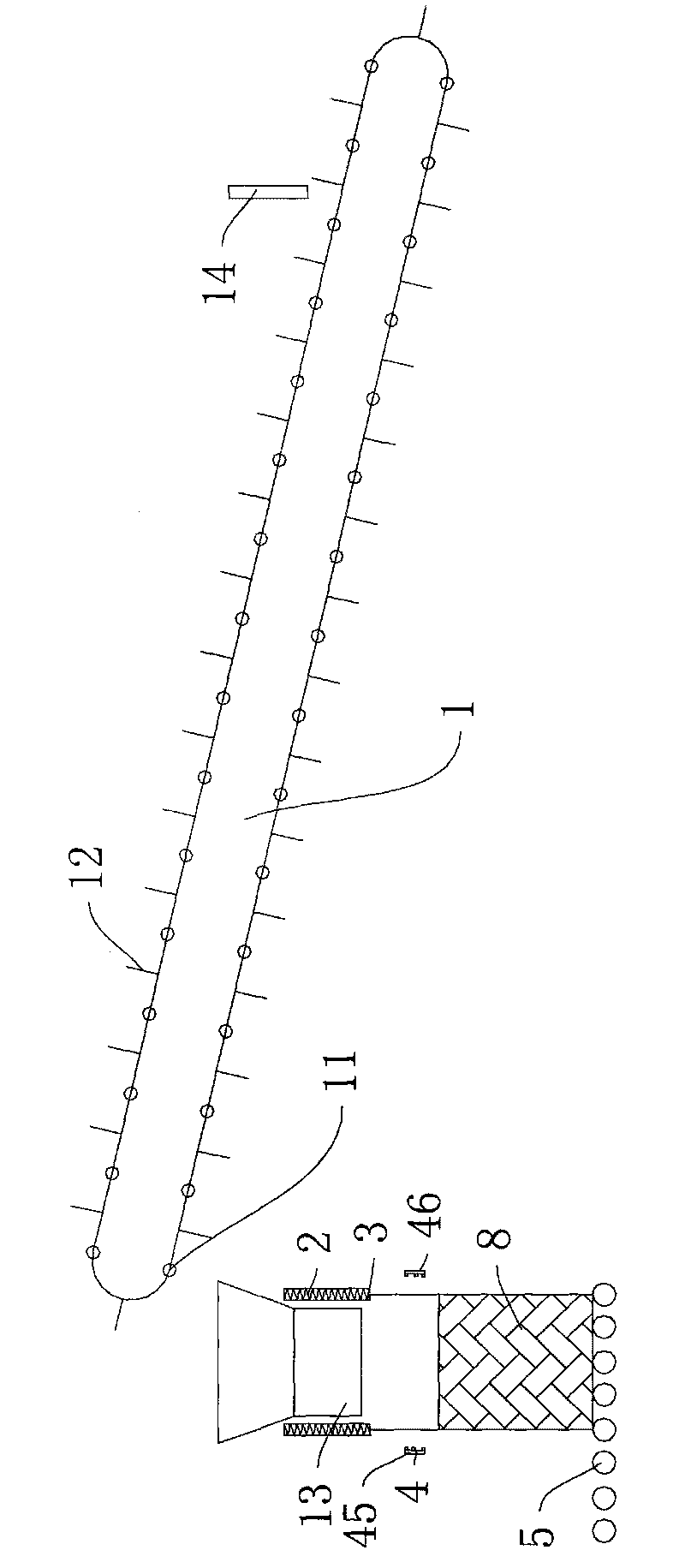

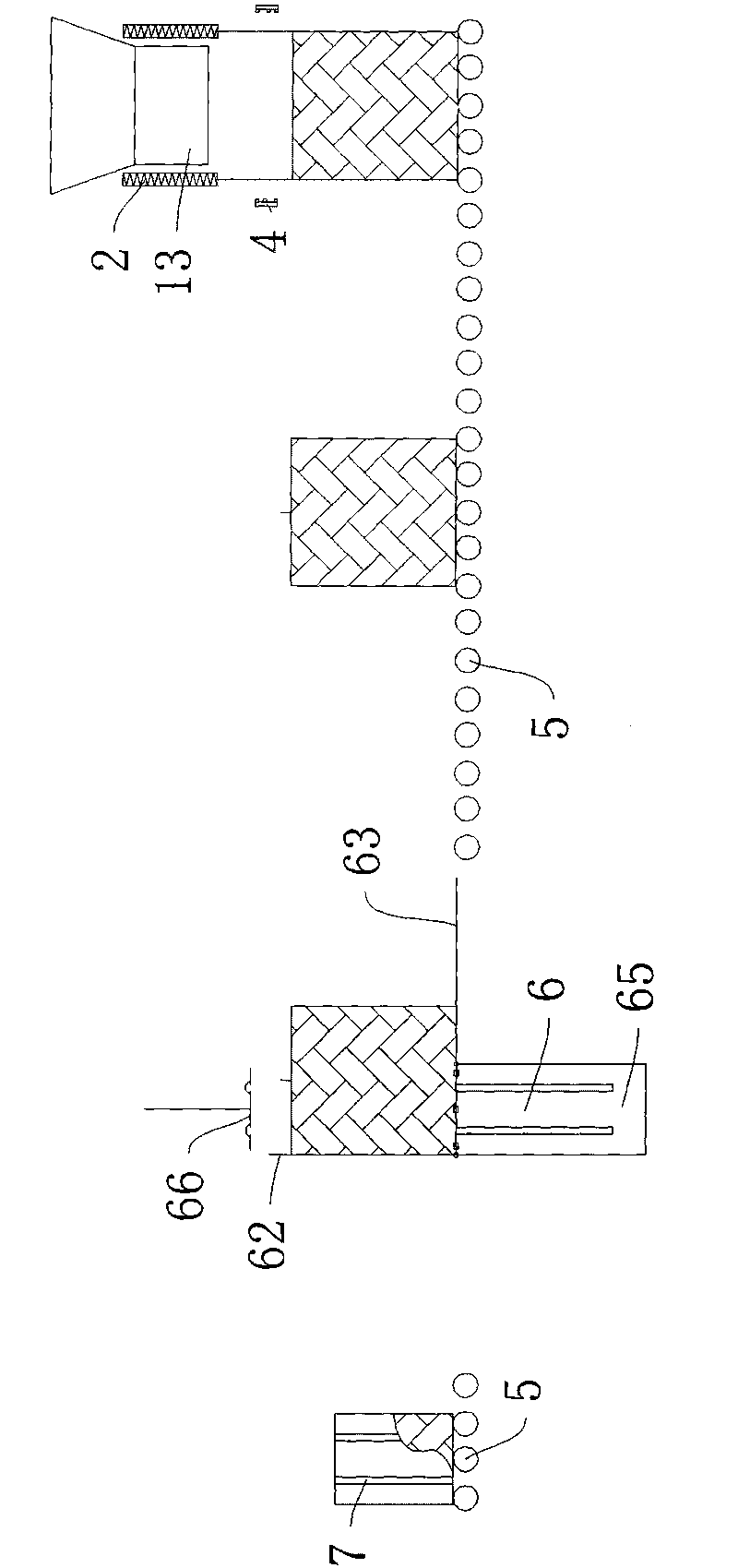

[0026] see figure 1 , 2 The shown wood chip scrap packaging line (wood chip scrap packaging equipment) includes a crawler conveyor 1 for conveying wood chips. In the crawler conveying device, each belt joint of the inclined crawler 11 is provided with a vertical baffle 12 of equal height and perpendicular to the crawler, the upper hanging scraper 14 is arranged above the baffle 12, and the lower end of the upper hanging scraper 14 is connected The upper ends of the baffle plate 12 are flush. After the wood chips are loaded, when the track is running, the wood chips that are higher than the baffle are scraped off by the upper hanging scraper, so that the height of the wood chips loaded in the adjacent baffles is flush with the baffles, so as to ensure the loading between adjacent baffles, etc. amount of wood chips.

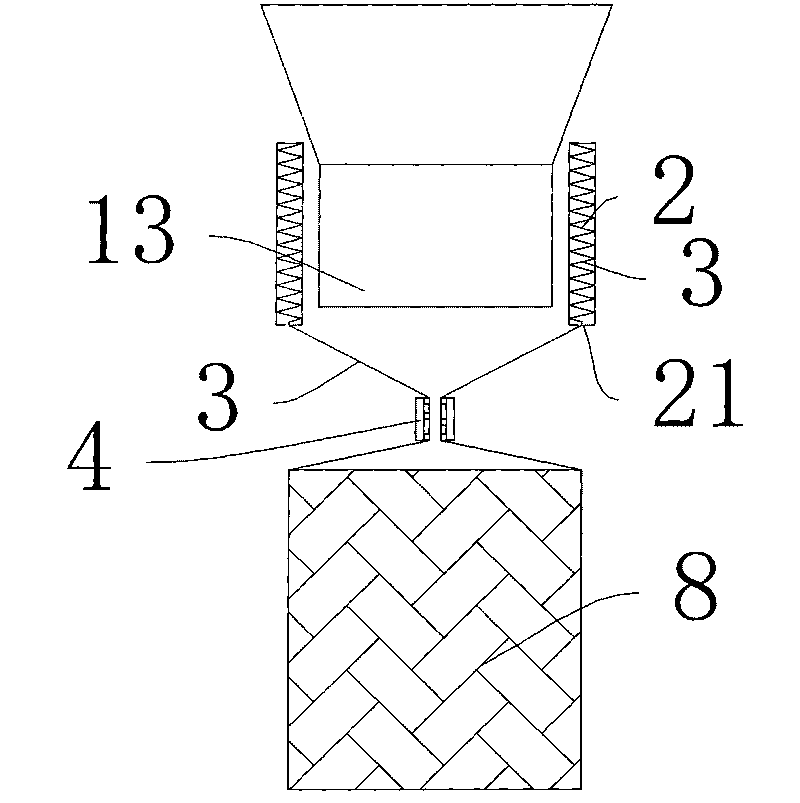

[0027] Around the discharge opening 13 of the crawler conveyor 1, a bag-releasing device 2 for storing and clamping plastic bags is provided, and a continuous p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com